What is Global HSS Cold Saw Blade Market?

The Global HSS Cold Saw Blade Market is a specialized segment within the broader industrial tools market, focusing on high-speed steel (HSS) cold saw blades. These blades are essential for precision cutting in various industries, offering superior performance due to their ability to maintain sharpness and resist wear even under high-speed operations. HSS cold saw blades are primarily used in metalworking applications, where they provide clean, accurate cuts with minimal burrs. This market is driven by the demand for efficient and durable cutting tools in sectors such as automotive, construction, and manufacturing. The blades are designed to cut through metals like steel and aluminum with ease, making them indispensable in settings where precision and speed are critical. As industries continue to evolve and demand more efficient production processes, the need for high-quality cutting tools like HSS cold saw blades is expected to grow. This market is characterized by continuous innovation, with manufacturers striving to enhance blade performance through advanced materials and cutting-edge technologies. The global reach of this market underscores its importance, as industries worldwide seek reliable solutions for their cutting needs.

M2 Tool Steel, M35 Tool Steel, Other in the Global HSS Cold Saw Blade Market:

M2 Tool Steel, M35 Tool Steel, and other variants play a crucial role in the Global HSS Cold Saw Blade Market, each offering distinct properties that cater to specific cutting requirements. M2 Tool Steel is one of the most commonly used materials for HSS cold saw blades due to its excellent toughness and wear resistance. It is a high-speed steel that contains tungsten, molybdenum, and vanadium, which contribute to its ability to withstand high temperatures and maintain sharpness over extended periods. This makes M2 Tool Steel ideal for cutting through hard metals and alloys, providing a balance between performance and cost-effectiveness. On the other hand, M35 Tool Steel is an upgraded version of M2, with the addition of cobalt. The presence of cobalt enhances the blade's red hardness, allowing it to perform efficiently at higher temperatures. This makes M35 Tool Steel suitable for more demanding applications where prolonged cutting at high speeds is required. The increased hardness and wear resistance of M35 Tool Steel make it a preferred choice for industries that require precision and durability, such as aerospace and automotive manufacturing. Apart from M2 and M35, there are other tool steels used in the production of HSS cold saw blades, each offering unique benefits. These may include variations with different alloy compositions designed to enhance specific properties like toughness, corrosion resistance, or cutting speed. The choice of tool steel depends on the specific application and the material being cut. For instance, some blades may be optimized for cutting softer metals, while others are designed for harder, more abrasive materials. The diversity in tool steel options allows manufacturers to tailor their products to meet the diverse needs of their customers, ensuring optimal performance across various industries. The ongoing development of new tool steel formulations reflects the dynamic nature of the Global HSS Cold Saw Blade Market, as manufacturers strive to meet the evolving demands of modern industrial applications. By leveraging advanced metallurgical techniques and innovative design approaches, the industry continues to push the boundaries of what is possible with HSS cold saw blades, delivering cutting solutions that are both efficient and reliable.

Metal Cutting, Pipe and Tube Manufacturing, Maintenance and Repair, Others in the Global HSS Cold Saw Blade Market:

The Global HSS Cold Saw Blade Market finds extensive usage across several key areas, including metal cutting, pipe and tube manufacturing, maintenance and repair, and other specialized applications. In metal cutting, HSS cold saw blades are prized for their ability to deliver precise, clean cuts with minimal burrs, making them ideal for use in industries such as automotive, aerospace, and construction. These blades are capable of cutting through a variety of metals, including steel, aluminum, and copper, with ease and efficiency. The precision and durability of HSS cold saw blades make them a preferred choice for manufacturers seeking to optimize their production processes and improve product quality. In pipe and tube manufacturing, HSS cold saw blades are essential for cutting pipes and tubes to precise lengths and specifications. The ability of these blades to maintain sharpness and resist wear under high-speed operations ensures consistent performance and reduces downtime, which is critical in high-volume production environments. The use of HSS cold saw blades in this sector helps manufacturers achieve tight tolerances and smooth finishes, which are essential for ensuring the integrity and performance of the final product. Maintenance and repair operations also benefit from the use of HSS cold saw blades, as they provide a reliable solution for cutting and shaping metal components. Whether it's repairing machinery, fabricating replacement parts, or performing routine maintenance, the versatility and durability of HSS cold saw blades make them an invaluable tool for maintenance professionals. The ability to cut through a wide range of materials with precision and ease allows for efficient repairs and minimizes downtime, ultimately contributing to improved operational efficiency. Beyond these primary applications, HSS cold saw blades are used in a variety of other specialized areas, such as custom metal fabrication, artistic metalworking, and even in the production of musical instruments. The adaptability of these blades to different cutting tasks and materials underscores their importance in the Global HSS Cold Saw Blade Market. As industries continue to evolve and demand more efficient and precise cutting solutions, the role of HSS cold saw blades is expected to expand, driven by ongoing innovations in blade design and material technology.

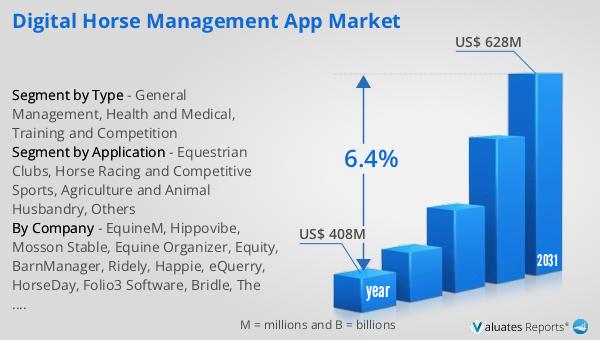

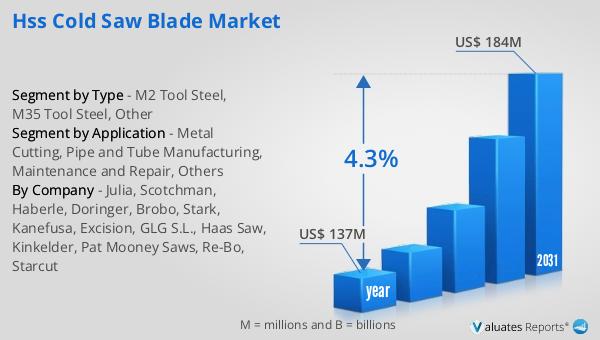

Global HSS Cold Saw Blade Market Outlook:

The global market for HSS Cold Saw Blades was valued at approximately $137 million in 2024, and it is anticipated to grow to a revised size of $184 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. This upward trend highlights the increasing demand for high-speed steel cold saw blades across various industries, driven by the need for efficient and precise cutting tools. The market's expansion is fueled by advancements in blade technology, which enhance cutting performance and durability, making these tools indispensable in sectors such as automotive, construction, and manufacturing. As industries continue to seek ways to optimize production processes and improve product quality, the demand for reliable and high-performance cutting solutions like HSS cold saw blades is expected to rise. The projected growth of the market underscores the importance of these blades in modern industrial applications, as they provide the precision and efficiency needed to meet the evolving demands of today's manufacturing landscape. The global reach of the market further emphasizes its significance, as industries worldwide rely on HSS cold saw blades to achieve their cutting needs with accuracy and reliability.

| Report Metric | Details |

| Report Name | HSS Cold Saw Blade Market |

| Accounted market size in year | US$ 137 million |

| Forecasted market size in 2031 | US$ 184 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Julia, Scotchman, Haberle, Doringer, Brobo, Stark, Kanefusa, Excision, GLG S.L., Haas Saw, Kinkelder, Pat Mooney Saws, Re-Bo, Starcut |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |