What is Global Heavy Duty Knife Gate Valve Market?

The Global Heavy Duty Knife Gate Valve Market is a specialized segment within the broader industrial valve industry, focusing on valves designed to handle challenging and abrasive materials. These valves are essential in industries where the flow of thick, viscous, or particulate-laden fluids needs to be controlled. Heavy duty knife gate valves are characterized by their robust construction, which allows them to cut through solid materials and provide a tight seal, preventing leakage. They are typically used in applications where other types of valves might fail due to the harsh conditions. The market for these valves is driven by the demand from industries such as mining, wastewater treatment, and pulp and paper, where the handling of slurry and other abrasive materials is common. As industries continue to expand and modernize, the need for reliable and efficient flow control solutions like heavy duty knife gate valves is expected to grow. These valves are crucial for maintaining operational efficiency and minimizing downtime, making them a vital component in industrial processes. The market is also influenced by technological advancements that enhance the performance and durability of these valves, ensuring they meet the rigorous demands of various applications.

Full-Flanged Type, Wafer-Style Type, Others in the Global Heavy Duty Knife Gate Valve Market:

In the Global Heavy Duty Knife Gate Valve Market, there are several types of valves, each designed to meet specific needs and applications. The Full-Flanged Type is one of the most common designs, featuring flanges on both ends of the valve body. This design allows for easy installation and removal, making it ideal for systems that require frequent maintenance or replacement. The full-flanged type provides a secure connection to the pipeline, ensuring a tight seal and preventing leaks. This type of valve is often used in applications where high pressure and temperature conditions are present, as the flanged design can withstand significant stress. The Wafer-Style Type, on the other hand, is a more compact and lightweight option. It is designed to fit between two flanges in a pipeline, held in place by bolts that pass through the flanges. This design is advantageous in systems where space is limited, as it requires less room for installation. The wafer-style valve is also easier to install and remove, making it a cost-effective choice for many applications. Despite its lighter construction, it still provides reliable performance in controlling the flow of abrasive materials. Other types of heavy duty knife gate valves include the lug-style and the through-conduit designs. The lug-style valve is similar to the wafer-style but features threaded lugs on the valve body, allowing it to be installed in systems where one side of the pipeline may need to be disconnected without affecting the other side. This design is particularly useful in applications where maintenance or repair work is frequently required. The through-conduit design, meanwhile, is engineered for applications that demand minimal pressure drop and high flow capacity. It features a full-bore opening, allowing for unobstructed flow of materials. This type of valve is often used in industries where the efficient handling of large volumes of slurry or other abrasive materials is critical. Each of these valve types plays a crucial role in the Global Heavy Duty Knife Gate Valve Market, offering unique benefits and capabilities to meet the diverse needs of industrial applications. As industries continue to evolve, the demand for specialized valve solutions is expected to grow, driving innovation and development in this market segment.

Mining, Electricity, Chemicals, Water Treatment, Others in the Global Heavy Duty Knife Gate Valve Market:

The Global Heavy Duty Knife Gate Valve Market finds extensive usage across various industries, each with its unique requirements and challenges. In the mining industry, these valves are indispensable for handling slurry, a mixture of water and finely ground rock, which is a byproduct of mineral processing. The robust construction of heavy duty knife gate valves allows them to cut through the thick slurry and provide a reliable seal, preventing leaks and ensuring efficient operation. This is crucial in mining operations, where downtime can lead to significant financial losses. In the electricity sector, heavy duty knife gate valves are used in power plants to control the flow of cooling water, ash slurry, and other fluids. Their ability to handle high-pressure and high-temperature conditions makes them ideal for such demanding applications. These valves help maintain the efficiency and safety of power generation processes, contributing to the overall reliability of the electricity supply. The chemical industry also relies heavily on these valves for handling corrosive and abrasive fluids. The materials used in the construction of heavy duty knife gate valves are chosen for their resistance to chemical attack, ensuring long service life and minimal maintenance requirements. This is particularly important in chemical processing, where the integrity of the flow control system is critical to preventing leaks and ensuring safe operation. In water treatment facilities, heavy duty knife gate valves are used to manage the flow of wastewater and sludge. Their ability to handle thick, particulate-laden fluids makes them ideal for this application, where efficient flow control is essential for the treatment process. These valves help ensure that water treatment plants operate smoothly, protecting the environment and public health. Other industries, such as pulp and paper, also benefit from the use of heavy duty knife gate valves. In these applications, the valves are used to control the flow of pulp slurry, a mixture of water and cellulose fibers. The ability of these valves to handle abrasive materials and provide a tight seal is crucial for maintaining the efficiency of the production process. Overall, the Global Heavy Duty Knife Gate Valve Market plays a vital role in supporting the operations of various industries, providing reliable and efficient flow control solutions that meet the demands of challenging applications.

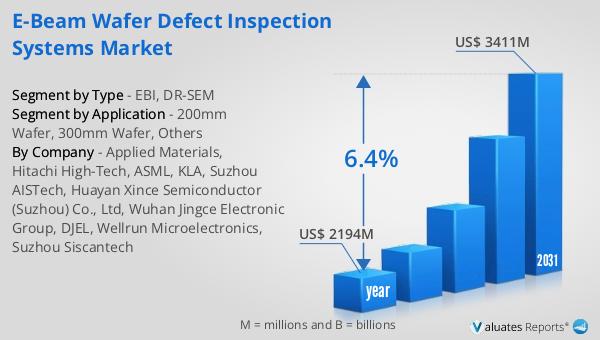

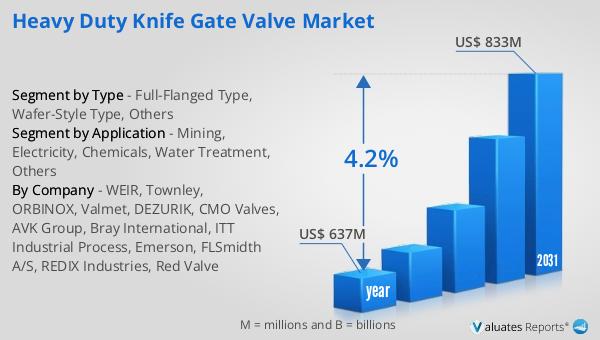

Global Heavy Duty Knife Gate Valve Market Outlook:

The global market for Heavy Duty Knife Gate Valves was valued at approximately $637 million in 2024. This market is anticipated to grow steadily, reaching an estimated size of $833 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. The increasing demand for these valves across various industries, such as mining, electricity, chemicals, and water treatment, is a key factor driving this growth. As industries continue to expand and modernize, the need for reliable and efficient flow control solutions becomes more critical. Heavy duty knife gate valves, with their robust construction and ability to handle abrasive and viscous materials, are well-suited to meet these demands. Additionally, technological advancements in valve design and materials are enhancing the performance and durability of these valves, further contributing to market growth. The market's expansion is also supported by the growing emphasis on operational efficiency and environmental sustainability, as industries seek to minimize downtime and reduce their environmental impact. As a result, the Global Heavy Duty Knife Gate Valve Market is poised for continued growth, offering significant opportunities for manufacturers and suppliers in this sector.

| Report Metric | Details |

| Report Name | Heavy Duty Knife Gate Valve Market |

| Accounted market size in year | US$ 637 million |

| Forecasted market size in 2031 | US$ 833 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | WEIR, Townley, ORBINOX, Valmet, DEZURIK, CMO Valves, AVK Group, Bray International, ITT Industrial Process, Emerson, FLSmidth A/S, REDIX Industries, Red Valve |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |