What is Global Machining Centers Market?

The Global Machining Centers Market is a dynamic and essential segment of the manufacturing industry, encompassing a wide range of machinery used for precision cutting, shaping, and finishing of metal and other materials. These machining centers are pivotal in producing complex parts and components with high accuracy and efficiency. The market is driven by the increasing demand for automation and precision in manufacturing processes across various industries, including automotive, aerospace, and medical equipment. Technological advancements, such as the integration of computer numerical control (CNC) systems, have significantly enhanced the capabilities of machining centers, allowing for greater flexibility and productivity. Additionally, the rise in industrialization and the need for high-quality products have further fueled the growth of this market. As industries continue to evolve, the Global Machining Centers Market is expected to expand, offering innovative solutions to meet the diverse needs of manufacturers worldwide. The market's growth is also supported by the increasing adoption of smart manufacturing practices, which emphasize efficiency, sustainability, and cost-effectiveness. Overall, the Global Machining Centers Market plays a crucial role in advancing manufacturing technologies and supporting economic development across the globe.

Vertical Machining Centers, Horizontal Machining Centers, Double-Column Machining Centers in the Global Machining Centers Market:

Vertical Machining Centers (VMCs), Horizontal Machining Centers (HMCs), and Double-Column Machining Centers are integral components of the Global Machining Centers Market, each offering unique capabilities and advantages. Vertical Machining Centers are characterized by their vertical spindle orientation, which makes them ideal for operations that require precision and speed, such as milling, drilling, and tapping. VMCs are widely used in industries where space is a constraint, as they typically occupy less floor space compared to their horizontal counterparts. They are particularly favored in the production of small to medium-sized components and are known for their versatility and ease of use. On the other hand, Horizontal Machining Centers feature a horizontal spindle orientation, which allows for the efficient machining of larger and heavier workpieces. HMCs are preferred for operations that require extensive material removal and are commonly used in the automotive and aerospace industries. Their design facilitates better chip evacuation, reducing the risk of tool damage and improving overall productivity. Double-Column Machining Centers, also known as gantry-type machining centers, are designed for handling large and heavy workpieces with high precision. These machines are equipped with two columns that support the spindle head, providing enhanced stability and rigidity during machining operations. Double-Column Machining Centers are ideal for applications that demand high accuracy and surface finish, such as the production of molds, dies, and large structural components. They are extensively used in industries like aerospace, automotive, and heavy machinery manufacturing. The choice between these types of machining centers depends on various factors, including the size and complexity of the workpiece, production volume, and specific industry requirements. Each type of machining center offers distinct advantages, making them indispensable tools in modern manufacturing processes. As the Global Machining Centers Market continues to evolve, manufacturers are increasingly focusing on developing advanced machining centers that incorporate cutting-edge technologies, such as automation, artificial intelligence, and the Internet of Things (IoT), to enhance performance and meet the growing demands of various industries.

Automotive, Mechanical Egineering, Tool Manufacturing, Medical Equipment, Aerospace & Defense, Others in the Global Machining Centers Market:

The Global Machining Centers Market finds extensive usage across a wide range of industries, each benefiting from the precision, efficiency, and versatility offered by these advanced machines. In the automotive industry, machining centers are crucial for producing various components, such as engine blocks, transmission cases, and suspension parts. The ability to achieve high precision and repeatability is essential in this sector, where quality and performance are paramount. Machining centers enable manufacturers to produce complex geometries and tight tolerances, ensuring that automotive components meet stringent industry standards. In the field of mechanical engineering, machining centers play a vital role in the production of machinery and equipment used in various applications. These machines are used to manufacture parts with intricate designs and high precision, contributing to the development of innovative engineering solutions. Tool manufacturing is another area where machining centers are indispensable. They are used to produce cutting tools, molds, and dies with exceptional accuracy and surface finish, ensuring the quality and longevity of the tools. In the medical equipment industry, machining centers are used to manufacture components for medical devices, such as surgical instruments, implants, and diagnostic equipment. The precision and reliability of machining centers are critical in this sector, where the quality of medical components can directly impact patient safety and outcomes. The aerospace and defense industries also rely heavily on machining centers for the production of complex components, such as turbine blades, aircraft frames, and missile parts. The ability to machine high-strength materials with precision and consistency is crucial in these sectors, where performance and safety are of utmost importance. Additionally, machining centers are used in various other industries, including electronics, energy, and consumer goods, where they contribute to the production of high-quality products with intricate designs and specifications. The versatility and adaptability of machining centers make them valuable assets in modern manufacturing, enabling industries to meet the ever-evolving demands of the global market.

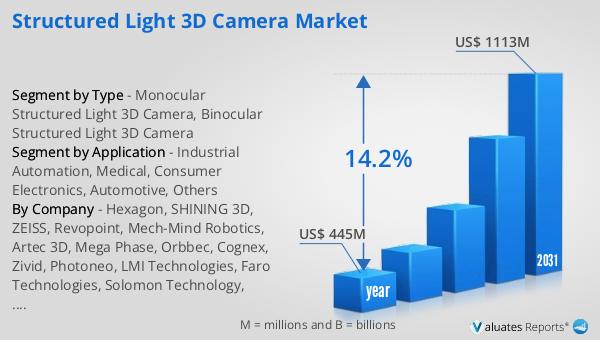

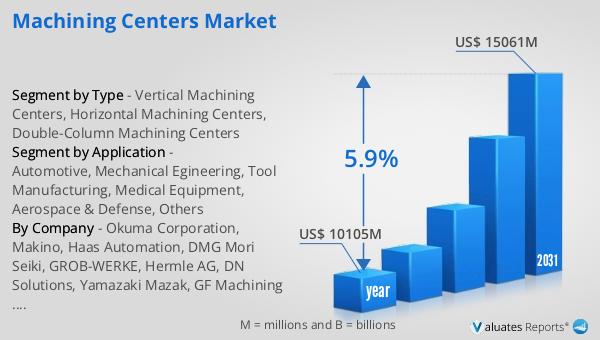

Global Machining Centers Market Outlook:

In 2024, the global market for Machining Centers was valued at approximately $10,105 million. This market is anticipated to experience significant growth, reaching an estimated size of $15,061 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.9% over the forecast period. The expansion of the Machining Centers Market can be attributed to several factors, including the increasing demand for precision manufacturing and automation across various industries. As manufacturers strive to enhance productivity and efficiency, the adoption of advanced machining centers is expected to rise. These machines offer the capability to produce complex components with high accuracy, meeting the stringent quality standards required in sectors such as automotive, aerospace, and medical equipment. Additionally, the integration of cutting-edge technologies, such as computer numerical control (CNC) systems and smart manufacturing practices, is driving the market's growth. These advancements enable manufacturers to optimize production processes, reduce operational costs, and improve overall product quality. As the global economy continues to recover and industrial activities gain momentum, the demand for machining centers is likely to increase, further propelling the market's expansion. The projected growth of the Global Machining Centers Market underscores the importance of these machines in modern manufacturing and their role in supporting economic development worldwide.

| Report Metric | Details |

| Report Name | Machining Centers Market |

| Accounted market size in year | US$ 10105 million |

| Forecasted market size in 2031 | US$ 15061 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Okuma Corporation, Makino, Haas Automation, DMG Mori Seiki, GROB-WERKE, Hermle AG, DN Solutions, Yamazaki Mazak, GF Machining Solutions, Shenzhen Create Century Machinery, Hyundai WIA, JTEKT Corporation, Haitian Precision, CHIRON Group SE, Fair Friend Group, Hurco Companies Inc, Neway CNC Equipment, Starrag Group, China General Technology, Jyoti CNC Automation, Qinchuan Machine Tool, SPINNER, EMAG Group, SMEC CO, INDEX-Werke, Alzmetall, RIFA Precision, FOM Industrie, Fidia S.p.A., CB Ferrari |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |