What is Global Ready to Press SiC Powder Market?

The Global Ready to Press SiC Powder Market is a specialized segment within the broader materials industry, focusing on silicon carbide (SiC) powders that are ready to be pressed into various forms for industrial applications. Silicon carbide is a compound of silicon and carbon known for its exceptional hardness, thermal conductivity, and resistance to wear and chemical corrosion. These properties make it an ideal material for a wide range of applications, from abrasives to electronics. The market for ready-to-press SiC powder is driven by the demand for high-performance materials in industries such as automotive, aerospace, electronics, and energy. The powder is engineered to have specific particle sizes and purity levels, which are crucial for achieving the desired performance characteristics in the final product. As industries continue to seek materials that can withstand extreme conditions and improve efficiency, the demand for ready-to-press SiC powder is expected to grow. This market is characterized by technological advancements in powder processing and a focus on sustainability, as manufacturers aim to reduce waste and energy consumption in production processes. The global reach of this market is evident as it caters to diverse industries across different regions, each with its unique requirements and standards.

Purity Above 85%, Purity Above 90%, Purity Above 98% in the Global Ready to Press SiC Powder Market:

In the Global Ready to Press SiC Powder Market, purity levels play a critical role in determining the suitability of the powder for various applications. Purity levels are typically categorized as above 85%, above 90%, and above 98%, each serving different industrial needs. SiC powder with a purity above 85% is often used in applications where extreme precision is not the primary concern, but where the material's inherent hardness and thermal properties are still beneficial. This level of purity is suitable for general-purpose industrial applications, such as certain types of abrasives and basic refractory materials, where cost-effectiveness is a priority. On the other hand, SiC powder with a purity above 90% is used in more demanding applications where higher performance is required. This includes more advanced refractory materials and some types of ceramics, where the material's ability to withstand high temperatures and corrosive environments is crucial. The higher purity ensures fewer impurities that could compromise the material's performance under stress. The highest purity level, above 98%, is reserved for the most demanding applications, such as in the semiconductor and electronics industries. Here, even the smallest impurities can significantly affect the performance of electronic components, making ultra-high purity SiC powder essential. This level of purity is also critical in advanced ceramics used in aerospace and defense applications, where material failure is not an option. The production of high-purity SiC powder involves advanced processing techniques to remove impurities and achieve the desired particle size distribution. This often includes processes such as chemical vapor deposition and advanced milling techniques. As the demand for high-performance materials continues to grow, the market for high-purity SiC powder is expected to expand, driven by innovations in processing technology and the increasing complexity of industrial applications. Manufacturers are continually investing in research and development to improve the purity and performance of SiC powders, aiming to meet the evolving needs of industries that rely on these advanced materials.

Industrial Abrasives And Tools, Ceramics, Refractory Materials, Semiconductor And Electronic Components, Other in the Global Ready to Press SiC Powder Market:

The Global Ready to Press SiC Powder Market finds its applications across various industries, each leveraging the unique properties of silicon carbide to enhance their products and processes. In the realm of industrial abrasives and tools, SiC powder is prized for its hardness and durability. It is used to manufacture grinding wheels, cutting tools, and sandpapers that can efficiently cut, grind, and polish hard materials like metals, stones, and ceramics. The ability of SiC to maintain its sharpness and resist wear makes it an ideal choice for these applications, where performance and longevity are critical. In the ceramics industry, SiC powder is used to produce advanced ceramics that are lightweight yet incredibly strong and resistant to thermal shock. These ceramics are used in applications ranging from armor plating to heat exchangers, where their ability to withstand extreme temperatures and mechanical stress is essential. The refractory materials industry also benefits from SiC powder, as it is used to produce linings for furnaces, kilns, and reactors. These linings must withstand high temperatures and corrosive environments, and SiC's thermal conductivity and chemical resistance make it an excellent choice. In the semiconductor and electronic components sector, high-purity SiC powder is used to produce substrates and components that can operate at high temperatures and voltages. This is particularly important in power electronics and high-frequency applications, where traditional materials like silicon may not perform adequately. Finally, SiC powder is used in a variety of other applications, including the production of brake discs, seals, and bearings, where its mechanical properties and resistance to wear and corrosion are advantageous. As industries continue to push the boundaries of performance and efficiency, the demand for SiC powder in these applications is expected to grow, driving innovation and development in the market.

Global Ready to Press SiC Powder Market Outlook:

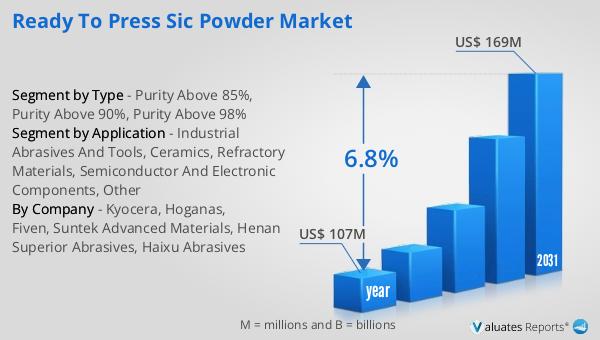

The global market for Ready to Press SiC Powder was valued at approximately $107 million in 2024, and projections indicate that it will grow to an estimated $169 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.8% over the forecast period. This upward trend is driven by the increasing demand for high-performance materials across various industries, including automotive, aerospace, electronics, and energy. As these industries continue to evolve and seek materials that can withstand extreme conditions and improve efficiency, the demand for ready-to-press SiC powder is expected to rise. The market's growth is also supported by advancements in powder processing technologies, which enable manufacturers to produce SiC powders with higher purity levels and more precise particle size distributions. These advancements are crucial for meeting the stringent requirements of industries that rely on SiC powder for critical applications. Additionally, the focus on sustainability and reducing waste in production processes is driving innovation in the market, as manufacturers strive to develop more efficient and environmentally friendly methods of producing SiC powder. As a result, the Global Ready to Press SiC Powder Market is poised for significant growth in the coming years, offering opportunities for manufacturers and suppliers to capitalize on the increasing demand for high-performance materials.

| Report Metric | Details |

| Report Name | Ready to Press SiC Powder Market |

| Accounted market size in year | US$ 107 million |

| Forecasted market size in 2031 | US$ 169 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kyocera, Hoganas, Fiven, Suntek Advanced Materials, Henan Superior Abrasives, Haixu Abrasives |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |