What is Global Wind Turbine Lubricants Market?

The Global Wind Turbine Lubricants Market is a specialized segment within the broader lubricants industry, focusing on the production and distribution of lubricants specifically designed for wind turbines. These lubricants play a crucial role in ensuring the efficient and reliable operation of wind turbines, which are pivotal in harnessing wind energy as a renewable power source. The market encompasses a variety of lubricant types, including synthetic and mineral oils, each tailored to meet the unique demands of wind turbine components such as gearboxes, bearings, and other moving parts. As the demand for renewable energy sources continues to rise, driven by environmental concerns and the need for sustainable energy solutions, the wind turbine lubricants market is experiencing significant growth. This growth is further fueled by technological advancements in lubricant formulations that enhance the performance and longevity of wind turbines, thereby reducing maintenance costs and downtime. The market is characterized by a competitive landscape with numerous players striving to innovate and offer high-performance lubricants that meet the evolving needs of the wind energy sector. Overall, the Global Wind Turbine Lubricants Market is a dynamic and rapidly expanding industry, integral to the advancement of renewable energy technologies.

Synthetic Oil, Mineral Oil in the Global Wind Turbine Lubricants Market:

In the realm of the Global Wind Turbine Lubricants Market, synthetic oil and mineral oil are two predominant types of lubricants, each offering distinct advantages and characteristics. Synthetic oils are engineered through chemical synthesis, resulting in a lubricant with superior performance attributes compared to conventional mineral oils. These oils are designed to withstand extreme temperatures, resist oxidation, and provide excellent protection against wear and tear, making them ideal for the demanding conditions within wind turbines. The molecular structure of synthetic oils is uniform, which enhances their stability and performance under varying operational conditions. This stability is crucial for wind turbines, which often operate in harsh environments with fluctuating temperatures and high mechanical stress. Synthetic oils also offer extended service intervals, reducing the frequency of lubricant changes and thereby lowering maintenance costs. This is particularly beneficial for offshore wind farms, where maintenance operations can be logistically challenging and costly. On the other hand, mineral oils are derived from refining crude oil and are generally more cost-effective than synthetic oils. While they may not offer the same level of performance as synthetic oils, advancements in refining processes have improved the quality and capabilities of mineral oils. They provide adequate lubrication for wind turbine components, especially in less demanding environments or where cost considerations are paramount. Mineral oils are often enhanced with additives to improve their performance, such as anti-wear agents, rust inhibitors, and antioxidants. These additives help to extend the life of the lubricant and protect the turbine components from damage. The choice between synthetic and mineral oils in the wind turbine lubricants market often depends on several factors, including the specific operational conditions of the wind farm, budget constraints, and maintenance strategies. As the wind energy sector continues to evolve, there is a growing trend towards the adoption of synthetic oils due to their superior performance and long-term cost benefits. However, mineral oils remain a viable option for many operators, particularly in regions where cost is a significant consideration. Both types of oils play a vital role in the efficient operation of wind turbines, contributing to the overall reliability and sustainability of wind energy as a renewable power source. The ongoing advancements in lubricant technology are expected to further enhance the capabilities of both synthetic and mineral oils, ensuring they meet the ever-increasing demands of the global wind energy industry.

Gearbox, Bearing, Other in the Global Wind Turbine Lubricants Market:

The usage of Global Wind Turbine Lubricants Market products is critical in several key areas of wind turbine operation, including gearboxes, bearings, and other components. Gearboxes are one of the most vital parts of a wind turbine, responsible for converting the low-speed rotation of the turbine blades into high-speed rotation that drives the generator. This conversion process involves significant mechanical stress and friction, making effective lubrication essential to prevent wear and tear, reduce heat generation, and ensure smooth operation. Lubricants used in gearboxes must possess excellent thermal stability, high load-carrying capacity, and resistance to oxidation to withstand the harsh operational conditions. Synthetic oils are often preferred for gearbox lubrication due to their superior performance characteristics, although high-quality mineral oils can also be used in certain applications. Bearings, another critical component of wind turbines, facilitate the smooth rotation of the blades and other moving parts. They are subjected to constant mechanical stress and environmental factors such as temperature fluctuations and moisture. Lubricants for bearings must provide excellent protection against wear, corrosion, and moisture ingress to ensure the longevity and reliability of the bearings. Both synthetic and mineral oils are used for bearing lubrication, with the choice often depending on the specific operational conditions and maintenance strategies of the wind farm. In addition to gearboxes and bearings, wind turbine lubricants are also used in other components such as hydraulic systems, pitch and yaw systems, and cooling systems. These components require specialized lubricants that can withstand the unique demands of their respective functions. For instance, hydraulic systems require lubricants with excellent viscosity stability and anti-wear properties, while pitch and yaw systems need lubricants that can operate effectively under varying loads and temperatures. The use of high-quality lubricants in these areas is crucial for minimizing downtime, reducing maintenance costs, and enhancing the overall efficiency and reliability of wind turbines. As the wind energy sector continues to grow, the demand for advanced lubricants that can meet the evolving needs of wind turbine technology is expected to increase. This trend underscores the importance of ongoing research and development in the field of wind turbine lubricants, as manufacturers strive to develop innovative solutions that enhance the performance and sustainability of wind energy systems.

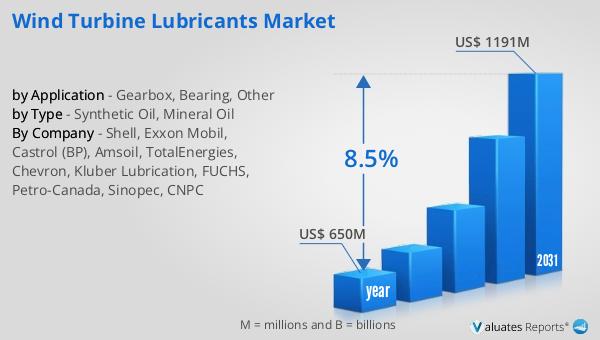

Global Wind Turbine Lubricants Market Outlook:

The global market for wind turbine lubricants was valued at $650 million in 2024, and it is anticipated to expand significantly, reaching an estimated $1,191 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.5% over the forecast period. This robust growth is indicative of the increasing demand for wind turbine lubricants, driven by the expanding wind energy sector and the need for efficient and reliable lubrication solutions. As wind energy continues to gain prominence as a sustainable and environmentally friendly power source, the demand for high-performance lubricants that can enhance the efficiency and longevity of wind turbines is expected to rise. The market's growth is also supported by technological advancements in lubricant formulations, which are designed to meet the specific needs of wind turbine components and operating conditions. These advancements are crucial for reducing maintenance costs, minimizing downtime, and ensuring the optimal performance of wind turbines. The competitive landscape of the wind turbine lubricants market is characterized by numerous players striving to innovate and offer products that meet the evolving demands of the industry. As the market continues to grow, it presents significant opportunities for manufacturers and suppliers to capitalize on the increasing demand for advanced lubrication solutions in the wind energy sector.

| Report Metric | Details |

| Report Name | Wind Turbine Lubricants Market |

| Accounted market size in year | US$ 650 million |

| Forecasted market size in 2031 | US$ 1191 million |

| CAGR | 8.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shell, Exxon Mobil, Castrol (BP), Amsoil, TotalEnergies, Chevron, Kluber Lubrication, FUCHS, Petro-Canada, Sinopec, CNPC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |