What is Global Ultrasonic Tool Holder Market?

The Global Ultrasonic Tool Holder Market is a specialized segment within the broader manufacturing and industrial tools industry. Ultrasonic tool holders are advanced devices used to enhance the precision and efficiency of machining processes. They utilize ultrasonic vibrations to improve the cutting performance of tools, making them particularly useful in high-precision applications. These tool holders are designed to reduce friction and heat during machining, which not only extends the life of the cutting tools but also improves the quality of the finished product. The market for these tool holders is driven by the increasing demand for high-precision components in various industries such as aerospace, automotive, and electronics. As manufacturers strive for greater efficiency and precision, the adoption of ultrasonic tool holders is expected to grow. The market is characterized by continuous technological advancements, with manufacturers focusing on developing more efficient and versatile tool holders to meet the evolving needs of their customers. The global reach of this market is expanding as more industries recognize the benefits of ultrasonic machining, leading to increased investments in research and development to further enhance the capabilities of these tools.

Integrated, Modular in the Global Ultrasonic Tool Holder Market:

In the Global Ultrasonic Tool Holder Market, the concepts of integrated and modular systems play a crucial role in defining the functionality and adaptability of these tools. Integrated ultrasonic tool holders are designed as a single cohesive unit where the ultrasonic transducer, power supply, and tool holder are combined into one system. This integration offers several advantages, such as reduced setup time and increased reliability, as there are fewer components that can fail. Integrated systems are often preferred in environments where space is limited or where the machining process requires a high degree of precision and stability. The seamless design of integrated tool holders ensures that the ultrasonic vibrations are transmitted efficiently to the cutting tool, enhancing the overall performance of the machining process. On the other hand, modular ultrasonic tool holders offer a different set of benefits. These systems are designed with interchangeable components, allowing users to customize the tool holder according to their specific needs. The modular approach provides greater flexibility, as users can easily swap out different parts of the system to accommodate various machining tasks. This adaptability is particularly beneficial in industries where the machining requirements frequently change, such as in prototyping or small-batch production. Modular systems also facilitate easier maintenance and repair, as individual components can be replaced without the need to dismantle the entire system. The choice between integrated and modular ultrasonic tool holders often depends on the specific requirements of the application and the preferences of the user. While integrated systems offer simplicity and reliability, modular systems provide versatility and customization. Both types of systems are essential in the Global Ultrasonic Tool Holder Market, catering to a wide range of industries and applications. As technology continues to advance, manufacturers are exploring ways to combine the benefits of both integrated and modular systems, creating hybrid solutions that offer the best of both worlds. These innovations are expected to drive further growth in the market, as more industries seek to leverage the advantages of ultrasonic machining for their manufacturing processes. The ongoing development of new materials and machining techniques is also contributing to the evolution of ultrasonic tool holders, as manufacturers strive to meet the increasing demands for precision and efficiency in modern manufacturing. As a result, the Global Ultrasonic Tool Holder Market is poised for significant growth, with integrated and modular systems playing a key role in shaping the future of this dynamic industry.

Semiconductor, Optical Components, Aerospace, Medical Devices, Others in the Global Ultrasonic Tool Holder Market:

The Global Ultrasonic Tool Holder Market finds its applications across various industries, each benefiting from the unique advantages offered by ultrasonic machining. In the semiconductor industry, ultrasonic tool holders are used to achieve the high precision required for manufacturing semiconductor components. The ability to produce intricate designs with minimal defects is crucial in this industry, and ultrasonic tool holders provide the necessary precision and control. The reduction in friction and heat during machining also helps in maintaining the integrity of delicate semiconductor materials. Similarly, in the production of optical components, ultrasonic tool holders are invaluable. The precision and smooth finish required for lenses and other optical parts are easily achieved with ultrasonic machining. The technology ensures that the surfaces are free from micro-cracks and other imperfections that could affect the performance of optical components. In the aerospace industry, the demand for lightweight and high-strength components is ever-increasing. Ultrasonic tool holders enable the machining of advanced materials such as titanium and composites, which are commonly used in aerospace applications. The precision and efficiency of ultrasonic machining help in producing components that meet the stringent quality standards of the aerospace industry. Medical devices also benefit from the use of ultrasonic tool holders. The precision required for manufacturing medical implants and instruments is critical, and ultrasonic machining provides the accuracy needed to produce these components. The technology also allows for the machining of biocompatible materials, ensuring that the finished products are safe for use in medical applications. Beyond these specific industries, ultrasonic tool holders are used in various other sectors where precision and efficiency are paramount. The versatility of ultrasonic machining makes it suitable for a wide range of applications, from automotive components to consumer electronics. As industries continue to demand higher precision and efficiency, the use of ultrasonic tool holders is expected to grow, driving further advancements in the technology and expanding its applications across different sectors.

Global Ultrasonic Tool Holder Market Outlook:

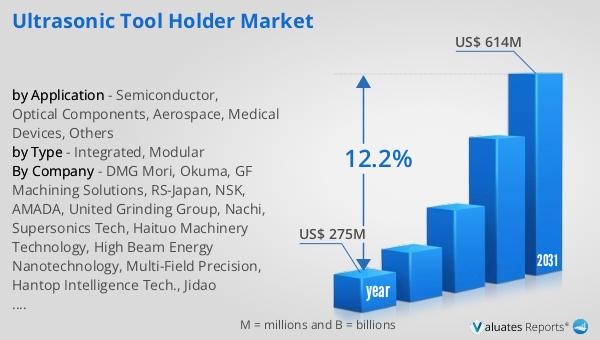

The outlook for the Global Ultrasonic Tool Holder Market is promising, with significant growth expected in the coming years. In 2024, the market was valued at approximately $275 million, and it is projected to reach a revised size of $614 million by 2031. This growth represents a compound annual growth rate (CAGR) of 12.2% during the forecast period. The increasing demand for high-precision machining solutions across various industries is a key driver of this growth. As manufacturers seek to improve the efficiency and quality of their production processes, the adoption of ultrasonic tool holders is expected to rise. The market is also benefiting from continuous technological advancements, with manufacturers developing more efficient and versatile tool holders to meet the evolving needs of their customers. The expansion of the market is further supported by the growing recognition of the benefits of ultrasonic machining, leading to increased investments in research and development. As a result, the Global Ultrasonic Tool Holder Market is poised for significant growth, with a bright future ahead as more industries embrace the advantages of ultrasonic machining for their manufacturing processes.

| Report Metric | Details |

| Report Name | Ultrasonic Tool Holder Market |

| Accounted market size in year | US$ 275 million |

| Forecasted market size in 2031 | US$ 614 million |

| CAGR | 12.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DMG Mori, Okuma, GF Machining Solutions, RS-Japan, NSK, AMADA, United Grinding Group, Nachi, Supersonics Tech, Haituo Machinery Technology, High Beam Energy Nanotechnology, Multi-Field Precision, Hantop Intelligence Tech., Jidao Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |