What is Global Ultrasonic Metal Welding Machine Sales Market?

The Global Ultrasonic Metal Welding Machine Sales Market refers to the worldwide industry focused on the production, distribution, and sale of machines that utilize ultrasonic technology to weld metal components together. Ultrasonic metal welding is a process that uses high-frequency ultrasonic vibrations to create solid-state welds between metals without melting them. This technique is highly valued for its ability to produce strong, reliable joints quickly and efficiently, making it a popular choice in industries such as automotive, electronics, and aerospace. The market for these machines is driven by the increasing demand for lightweight and durable metal components, as well as the need for environmentally friendly and energy-efficient manufacturing processes. As industries continue to innovate and seek more efficient production methods, the demand for ultrasonic metal welding machines is expected to grow, with manufacturers focusing on developing advanced technologies to meet the evolving needs of their customers. The market is characterized by a mix of established players and new entrants, all competing to offer the most advanced and cost-effective solutions to their clients.

in the Global Ultrasonic Metal Welding Machine Sales Market:

In the Global Ultrasonic Metal Welding Machine Sales Market, various types of machines are utilized by different customers based on their specific needs and applications. One of the primary types is the Spot Ultrasonic Metal Welder, which is widely used for its ability to create precise and strong welds in small areas. This type of welder is particularly popular in the automotive industry, where it is used to join thin metal sheets and components in car bodies and other parts. Another type is the Seam Ultrasonic Metal Welder, which is designed for continuous welding along a seam or joint. This type of machine is often used in the production of metal tubes, pipes, and other cylindrical components, where a continuous weld is required for strength and durability. Additionally, there are Wire Splicing Ultrasonic Metal Welders, which are specifically designed for joining electrical wires and cables. These machines are commonly used in the electronics and electrical industries, where they provide a reliable and efficient method for creating strong connections between wires. Another important type is the Tube Sealing Ultrasonic Metal Welder, which is used to seal the ends of metal tubes and containers. This type of machine is often used in the packaging industry, where it provides a secure and leak-proof seal for metal containers. Each type of ultrasonic metal welding machine is designed to meet the specific needs of different industries and applications, offering a range of features and capabilities to ensure optimal performance and efficiency. Customers in the market for these machines typically consider factors such as the type of materials they need to weld, the size and shape of the components, and the required strength and durability of the welds. Manufacturers in the market are continually innovating and developing new technologies to meet the evolving needs of their customers, offering machines with advanced features such as automated controls, real-time monitoring, and enhanced precision and accuracy. As the demand for ultrasonic metal welding machines continues to grow, manufacturers are also focusing on developing more energy-efficient and environmentally friendly solutions, helping customers reduce their carbon footprint and meet sustainability goals. Overall, the Global Ultrasonic Metal Welding Machine Sales Market offers a wide range of options for customers, with machines designed to meet the specific needs and requirements of different industries and applications.

in the Global Ultrasonic Metal Welding Machine Sales Market:

The Global Ultrasonic Metal Welding Machine Sales Market serves a wide range of applications across various industries, each benefiting from the unique advantages of ultrasonic welding technology. In the automotive industry, ultrasonic metal welding machines are used extensively for joining thin metal sheets and components, such as car bodies, exhaust systems, and fuel tanks. The ability to create strong, reliable welds without the need for additional materials or adhesives makes ultrasonic welding an ideal choice for automotive manufacturers looking to reduce weight and improve fuel efficiency. In the electronics industry, ultrasonic metal welding machines are used to join electrical wires, connectors, and other components, providing a reliable and efficient method for creating strong connections. This is particularly important in the production of electronic devices, where the integrity of electrical connections is critical to the performance and reliability of the final product. The aerospace industry also relies on ultrasonic metal welding machines for the production of lightweight and durable components, such as aircraft panels and structural parts. The ability to create strong, reliable welds without the need for additional materials or adhesives makes ultrasonic welding an ideal choice for aerospace manufacturers looking to reduce weight and improve fuel efficiency. In the medical industry, ultrasonic metal welding machines are used to join metal components in medical devices and equipment, such as surgical instruments and implants. The ability to create strong, reliable welds without the need for additional materials or adhesives makes ultrasonic welding an ideal choice for medical manufacturers looking to ensure the safety and reliability of their products. Additionally, the packaging industry uses ultrasonic metal welding machines to seal metal containers and tubes, providing a secure and leak-proof seal that is essential for preserving the integrity and quality of the contents. Overall, the Global Ultrasonic Metal Welding Machine Sales Market serves a wide range of applications across various industries, each benefiting from the unique advantages of ultrasonic welding technology.

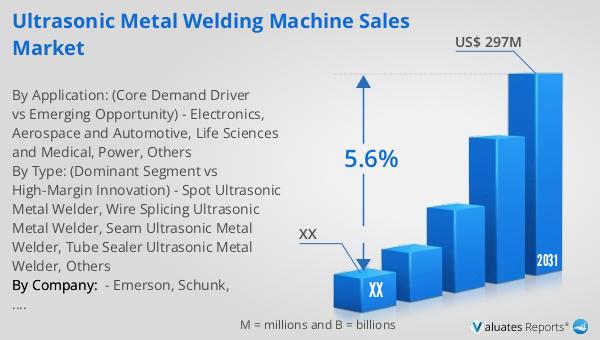

Global Ultrasonic Metal Welding Machine Sales Market Outlook:

The global Ultrasonic Metal Welding Machine market is projected to grow significantly in the coming years. In 2024, the market size was valued at approximately US$ 204 million, and it is anticipated to reach an adjusted size of US$ 297 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period from 2025 to 2031. The market is dominated by the top four manufacturers, who collectively hold a substantial share of about 75%. Geographically, North America represents the largest market, accounting for over 30% of the total market share. This is followed by Europe and the Asia-Pacific region, which together hold a combined share of over 55%. In terms of product segments, the Spot Ultrasonic Metal Welder is the largest, with a market share exceeding 30%. This segment's prominence is attributed to its widespread application across various industries, including automotive and electronics, where precision and reliability are paramount. The market's growth is driven by the increasing demand for lightweight and durable metal components, as well as the need for environmentally friendly and energy-efficient manufacturing processes. As industries continue to innovate and seek more efficient production methods, the demand for ultrasonic metal welding machines is expected to grow, with manufacturers focusing on developing advanced technologies to meet the evolving needs of their customers.

| Report Metric | Details |

| Report Name | Ultrasonic Metal Welding Machine Sales Market |

| Forecasted market size in 2031 | US$ 297 million |

| CAGR | 5.6% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Emerson, Schunk, Herrmann Ultraschalltechnik, Telsonic, Nippon Avionics, Sonics & Materials, TECH-SONIC, Kormax System, Chuxin, Sonobond |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |