What is Global Steel Powder Sales Market?

The global steel powder sales market is a dynamic and essential segment of the broader materials industry, playing a crucial role in various manufacturing processes. Steel powder is a fine, granular form of steel that is used in a wide range of applications, from automotive components to industrial machinery. The market for steel powder is driven by the demand for high-performance materials that can be used in advanced manufacturing techniques such as powder metallurgy and additive manufacturing. These techniques allow for the production of complex shapes and structures that would be difficult or impossible to achieve with traditional manufacturing methods. The global steel powder market is characterized by a diverse range of products, each tailored to specific applications and performance requirements. As industries continue to innovate and seek more efficient and sustainable production methods, the demand for steel powder is expected to grow, making it a vital component of the modern manufacturing landscape. The market is also influenced by factors such as technological advancements, environmental regulations, and the availability of raw materials, all of which can impact the supply and demand dynamics of steel powder.

in the Global Steel Powder Sales Market:

In the global steel powder sales market, various types of steel powder are utilized by customers based on their specific needs and applications. One of the most common types is atomized steel powder, which is produced by spraying molten steel into a chamber where it solidifies into fine particles. This type of powder is highly valued for its uniform particle size and shape, making it ideal for applications that require high precision and consistency, such as in the automotive and aerospace industries. Another type is reduced iron powder, which is produced by reducing iron ore in a furnace. This type of powder is often used in applications where cost is a significant factor, as it is generally less expensive than atomized powder. Additionally, there are alloyed steel powders, which are created by adding other elements to the steel to enhance its properties, such as strength, hardness, or corrosion resistance. These powders are used in applications that require specific performance characteristics, such as in the production of high-strength components for the construction and energy sectors. Furthermore, pre-alloyed powders, which are made by melting and atomizing a mixture of metals, offer a high degree of uniformity and are used in applications that demand consistent material properties. Each type of steel powder has its own set of advantages and limitations, and the choice of which to use depends on factors such as the desired properties of the final product, the manufacturing process being used, and the cost considerations. As the market continues to evolve, new types of steel powders are being developed to meet the changing needs of industries, offering improved performance and sustainability. The versatility of steel powder makes it an indispensable material in modern manufacturing, enabling the production of complex and high-performance components across a wide range of industries.

in the Global Steel Powder Sales Market:

Steel powder finds applications in a multitude of industries, each leveraging its unique properties to enhance their manufacturing processes and end products. In the automotive industry, steel powder is used extensively in the production of parts such as gears, bearings, and other components that require high strength and durability. The use of powder metallurgy allows for the production of complex shapes with minimal waste, making it a cost-effective solution for mass production. In the aerospace industry, steel powder is used in the manufacturing of lightweight and high-strength components, which are essential for improving fuel efficiency and performance. The ability to produce intricate shapes and structures using additive manufacturing techniques also allows for greater design flexibility and innovation. In the medical field, steel powder is used in the production of surgical instruments and implants, where biocompatibility and precision are critical. The use of steel powder in these applications allows for the creation of complex geometries that are tailored to the specific needs of patients. Additionally, in the energy sector, steel powder is used in the production of components for wind turbines, solar panels, and other renewable energy technologies. The demand for sustainable and efficient energy solutions is driving the development of new steel powder formulations that offer improved performance and durability. Furthermore, steel powder is used in the production of consumer goods, such as electronics and appliances, where it contributes to the miniaturization and enhancement of product performance. The versatility and adaptability of steel powder make it a valuable material in a wide range of applications, supporting innovation and efficiency across multiple industries. As the demand for high-performance materials continues to grow, the applications of steel powder are expected to expand, offering new opportunities for manufacturers and consumers alike.

Global Steel Powder Sales Market Outlook:

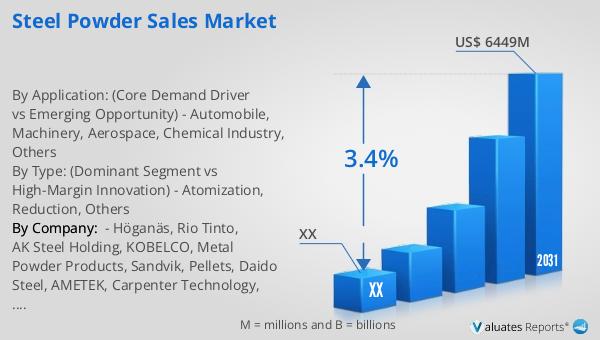

The global steel powder market is poised for significant growth in the coming years. In 2024, the market size was valued at approximately US$ 5,120 million, and it is projected to reach an adjusted size of US$ 6,449 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2025 to 2031. This growth is driven by the increasing demand for steel powder in various industries, including automotive, aerospace, and energy, where it is used to produce high-performance components. The market is dominated by a few key players, with the top five companies holding a combined market share of about 60%. This concentration of market power highlights the competitive nature of the industry and the importance of innovation and technological advancements in maintaining a competitive edge. Among the different types of steel powder, atomization is the largest segment, accounting for approximately 65% of the market. This is due to the superior properties of atomized steel powder, such as its uniform particle size and shape, which make it ideal for precision applications. As industries continue to seek more efficient and sustainable manufacturing solutions, the demand for high-quality steel powder is expected to rise, driving further growth in the market.

| Report Metric | Details |

| Report Name | Steel Powder Sales Market |

| Forecasted market size in 2031 | US$ 6449 million |

| CAGR | 3.4% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Höganäs, Rio Tinto, AK Steel Holding, KOBELCO, Metal Powder Products, Sandvik, Pellets, Daido Steel, AMETEK, Carpenter Technology, Pometon Powder, NANOSTEEL, Laiwu Iron&Steel Group, Jiande Yitong, Wuhan Iron&Steel Group, Ma Steel, Haining Feida |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |