What is Global Small Batch Prototyping Market?

The Global Small Batch Prototyping Market is a dynamic and evolving sector that caters to the need for producing limited quantities of prototypes quickly and efficiently. This market is crucial for industries that require rapid development and testing of new products before mass production. Small batch prototyping allows companies to experiment with design, functionality, and materials without the commitment of large-scale manufacturing. This approach is particularly beneficial for startups and small businesses that need to innovate rapidly while managing costs. The market encompasses various technologies and methods, including additive manufacturing, CNC machining, injection molding, vacuum casting, and sheet metal prototyping. Each of these techniques offers unique advantages, such as speed, precision, and material versatility, making them suitable for different applications across industries. As businesses increasingly prioritize agility and innovation, the demand for small batch prototyping continues to grow, driving advancements in technology and expanding the market's reach globally. This market not only supports product development but also fosters creativity and innovation, enabling companies to bring new ideas to life efficiently and cost-effectively.

Additive Manufacturing, CNC Machining, Injection Molding, Vacuum Casting, Sheet Metal Prototyping in the Global Small Batch Prototyping Market:

Additive manufacturing, commonly known as 3D printing, is a cornerstone of the Global Small Batch Prototyping Market. This technology builds objects layer by layer from digital models, allowing for complex geometries and intricate designs that traditional methods might struggle to achieve. It's particularly advantageous for creating prototypes with detailed features and for testing different materials, as it supports a wide range of plastics, metals, and composites. CNC machining, on the other hand, involves the use of computer-controlled machines to remove material from a solid block to create a desired shape. This method is known for its precision and is ideal for producing prototypes that require tight tolerances and high-quality finishes. It's widely used in industries where accuracy is paramount, such as aerospace and automotive. Injection molding is another critical process in small batch prototyping, especially for plastic parts. It involves injecting molten material into a mold to form a part. This method is efficient for producing multiple copies of a prototype quickly and is often used when the design is nearing finalization. Vacuum casting is a technique used to create high-quality prototypes that mimic the properties of production parts. It involves creating a silicone mold from a master model and then using it to cast parts in a vacuum chamber. This process is beneficial for producing prototypes with fine details and smooth surfaces, often used in consumer goods and medical devices. Lastly, sheet metal prototyping involves cutting, bending, and assembling metal sheets to create prototypes. This method is essential for industries like automotive and aerospace, where metal components are prevalent. Each of these technologies plays a vital role in the small batch prototyping market, offering unique benefits that cater to the diverse needs of different industries. By leveraging these methods, companies can accelerate their product development cycles, reduce costs, and improve the overall quality of their prototypes.

Product Design, Medical Devices, Automotive Parts, Aerospace & Defense, Architecture, Consumer Goods, Jewelry & Fashion, Others in the Global Small Batch Prototyping Market:

The Global Small Batch Prototyping Market finds extensive application across various sectors, each benefiting uniquely from the ability to produce prototypes quickly and efficiently. In product design, small batch prototyping allows designers to iterate rapidly, testing different concepts and materials to refine their ideas before committing to full-scale production. This flexibility is crucial for innovation, enabling designers to explore creative solutions without the constraints of traditional manufacturing. In the medical devices sector, prototyping is essential for developing new tools and equipment that meet stringent regulatory standards. Small batch prototyping allows for the creation of functional models that can be tested for usability and safety, ensuring that the final product is both effective and compliant. Automotive parts manufacturers use small batch prototyping to test new designs and materials, improving performance and safety while reducing time to market. This approach is particularly valuable in an industry where innovation is key to staying competitive. In aerospace and defense, prototyping is used to develop components that meet rigorous performance and safety standards. The ability to produce small batches of prototypes allows for thorough testing and validation, ensuring that the final products are reliable and effective. Architecture firms use prototyping to create scale models of buildings and structures, allowing for detailed visualization and analysis of design concepts. This process helps architects and clients make informed decisions about design and construction. In the consumer goods sector, small batch prototyping enables companies to test new products with consumers before launching them on a larger scale. This approach reduces risk and increases the likelihood of market success. In the jewelry and fashion industries, prototyping allows designers to experiment with new styles and materials, creating unique pieces that stand out in a competitive market. Finally, other industries, such as electronics and home appliances, also benefit from small batch prototyping, using it to develop innovative products that meet the changing needs of consumers. Overall, the Global Small Batch Prototyping Market plays a crucial role in driving innovation and efficiency across a wide range of industries, enabling companies to bring new products to market faster and more effectively.

Global Small Batch Prototyping Market Outlook:

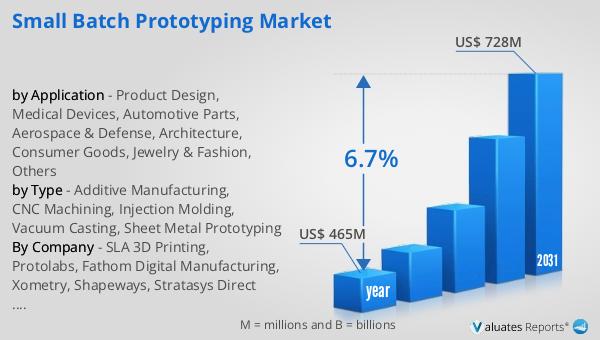

The Global Small Batch Prototyping Market is experiencing significant growth, with its value estimated at $465 million in 2024. This market is projected to expand to a revised size of $728 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.7% over the forecast period. This growth is driven by the increasing demand for rapid prototyping solutions across various industries, as companies seek to innovate and bring new products to market more quickly. The ability to produce small batches of prototypes allows businesses to test and refine their designs before committing to large-scale production, reducing risk and improving the overall quality of their products. As technology continues to advance, the capabilities of small batch prototyping are expanding, offering new opportunities for companies to explore creative solutions and improve their product development processes. This market is not only supporting innovation but also driving economic growth by enabling companies to compete more effectively in a global marketplace. With its projected growth, the Global Small Batch Prototyping Market is poised to play an increasingly important role in shaping the future of product development and manufacturing.

| Report Metric | Details |

| Report Name | Small Batch Prototyping Market |

| Accounted market size in year | US$ 465 million |

| Forecasted market size in 2031 | US$ 728 million |

| CAGR | 6.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SLA 3D Printing, Protolabs, Fathom Digital Manufacturing, Xometry, Shapeways, Stratasys Direct Manufacturing, Fast Radius, Voodoo Manufacturing, Nexa3D, Sculpteo, 3D Hubs |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |