What is Global Pneumatic Butter Pump Market?

The Global Pneumatic Butter Pump Market is a specialized segment within the broader industrial equipment sector, focusing on devices designed to efficiently transfer viscous substances like butter and similar materials. These pumps are powered by compressed air, making them highly efficient and reliable for continuous operation in various industrial settings. The market for pneumatic butter pumps is driven by the need for efficient and hygienic transfer of viscous materials in industries such as food processing, pharmaceuticals, and cosmetics. These pumps are particularly valued for their ability to handle high-viscosity substances without causing contamination or degradation of the product. The global market is characterized by a diverse range of products, each designed to meet specific industrial needs, from small-scale operations to large manufacturing facilities. As industries continue to seek more efficient and sustainable solutions for material handling, the demand for pneumatic butter pumps is expected to grow, driven by advancements in technology and increasing awareness of the benefits of pneumatic systems over traditional mechanical pumps. The market is also influenced by regulatory standards that emphasize hygiene and efficiency, further propelling the adoption of these pumps across various sectors.

Single Acting Pneumatic Grease Pump, Double Acting Pneumatic Grease Pump, Other in the Global Pneumatic Butter Pump Market:

In the Global Pneumatic Butter Pump Market, there are several types of pumps, each designed to meet specific industrial needs. The Single Acting Pneumatic Grease Pump is a type of pump that operates with a single stroke mechanism. It uses compressed air to move a piston in one direction, which in turn moves the grease or butter through the pump. This type of pump is typically used in applications where a continuous flow of material is not required, making it ideal for smaller operations or where precise control over the amount of material dispensed is necessary. The simplicity of the single acting pump makes it easy to maintain and operate, which is a significant advantage in industries where downtime can be costly. On the other hand, the Double Acting Pneumatic Grease Pump is designed for applications that require a continuous flow of material. This pump uses compressed air to move a piston back and forth, allowing for a more consistent and efficient transfer of grease or butter. The double acting mechanism ensures that there is always material being moved through the pump, which is crucial in high-demand environments such as large manufacturing facilities. The continuous operation of the double acting pump reduces the risk of interruptions in the production process, making it a preferred choice for many industries. In addition to these two main types, there are other variations of pneumatic butter pumps available in the market. These include pumps with specialized features such as variable speed control, which allows for more precise handling of materials, and pumps designed for specific applications such as high-pressure environments or those requiring a high degree of hygiene. These specialized pumps are often used in industries such as pharmaceuticals and food processing, where the quality and safety of the product are of utmost importance. The choice of pump depends on several factors, including the type of material being handled, the required flow rate, and the specific needs of the application. As technology continues to advance, the range of options available in the pneumatic butter pump market is expected to expand, offering even more tailored solutions for industrial material handling.

Automobile Industry, Construction Machinery, Port Transportation, Mining and Metallurgy, Other in the Global Pneumatic Butter Pump Market:

The Global Pneumatic Butter Pump Market finds extensive usage across various industries due to its efficiency and reliability in handling viscous materials. In the Automobile Industry, these pumps are used for the lubrication of machinery and components. The ability to handle high-viscosity substances makes pneumatic butter pumps ideal for ensuring that automotive parts are adequately lubricated, reducing wear and tear and extending the lifespan of the components. This is particularly important in the production and maintenance of vehicles, where precision and reliability are crucial. In the Construction Machinery sector, pneumatic butter pumps are used to lubricate heavy machinery and equipment. The harsh conditions and demanding environments in construction require equipment that can withstand significant wear and tear. Pneumatic butter pumps ensure that machinery is well-lubricated, reducing the risk of breakdowns and increasing operational efficiency. This is essential for maintaining productivity and minimizing downtime on construction sites. Port Transportation also benefits from the use of pneumatic butter pumps. The equipment used in ports, such as cranes and forklifts, requires regular maintenance to ensure smooth operation. Pneumatic butter pumps provide an efficient solution for lubricating these machines, ensuring that they operate reliably and efficiently. This is crucial in a port environment, where delays can have significant financial implications. In the Mining and Metallurgy industries, pneumatic butter pumps are used to lubricate machinery and equipment used in the extraction and processing of minerals. The harsh and demanding conditions in these industries require equipment that is robust and reliable. Pneumatic butter pumps provide a solution that ensures machinery is well-maintained, reducing the risk of breakdowns and increasing operational efficiency. This is essential for maintaining productivity and minimizing downtime in these industries. Other industries that benefit from the use of pneumatic butter pumps include food processing, pharmaceuticals, and cosmetics. In these industries, the ability to handle high-viscosity substances without causing contamination or degradation of the product is crucial. Pneumatic butter pumps provide a hygienic and efficient solution for transferring materials, ensuring that the quality and safety of the product are maintained. As industries continue to seek more efficient and sustainable solutions for material handling, the demand for pneumatic butter pumps is expected to grow, driven by advancements in technology and increasing awareness of the benefits of pneumatic systems over traditional mechanical pumps.

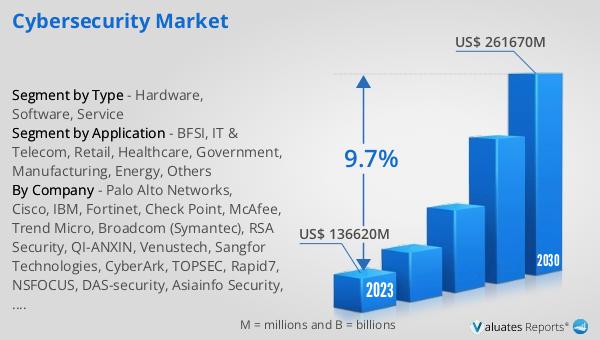

Global Pneumatic Butter Pump Market Outlook:

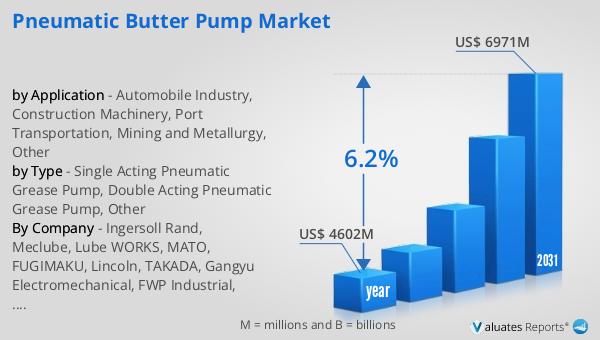

The global market for Pneumatic Butter Pump was valued at approximately $4,602 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $6,971 million by 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 6.2% over the forecast period. The increasing demand for efficient and reliable material handling solutions across various industries is a key driver of this growth. Pneumatic butter pumps are valued for their ability to handle high-viscosity substances without causing contamination or degradation of the product, making them an ideal choice for industries such as food processing, pharmaceuticals, and cosmetics. The market is also influenced by regulatory standards that emphasize hygiene and efficiency, further propelling the adoption of these pumps across various sectors. As industries continue to seek more efficient and sustainable solutions for material handling, the demand for pneumatic butter pumps is expected to grow, driven by advancements in technology and increasing awareness of the benefits of pneumatic systems over traditional mechanical pumps. The market is characterized by a diverse range of products, each designed to meet specific industrial needs, from small-scale operations to large manufacturing facilities. As technology continues to advance, the range of options available in the pneumatic butter pump market is expected to expand, offering even more tailored solutions for industrial material handling.

| Report Metric | Details |

| Report Name | Pneumatic Butter Pump Market |

| Accounted market size in year | US$ 4602 million |

| Forecasted market size in 2031 | US$ 6971 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ingersoll Rand, Meclube, Lube WORKS, MATO, FUGIMAKU, Lincoln, TAKADA, Gangyu Electromechanical, FWP Industrial, Zhushan Jixie, EQUAN Pumb, Jolong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |