What is Global Niobium Carbide Sales Market?

The Global Niobium Carbide Sales Market is a specialized segment within the broader materials market, focusing on the production, distribution, and sale of niobium carbide. Niobium carbide is a hard, refractory ceramic material that is highly valued for its exceptional hardness, high melting point, and resistance to corrosion and wear. These properties make it an essential component in various industrial applications, particularly in the manufacturing of cutting tools, wear-resistant coatings, and high-temperature structural materials. The market for niobium carbide is driven by its demand in industries such as aerospace, automotive, and electronics, where advanced materials are crucial for enhancing performance and durability. The global market is characterized by a few key players who dominate production and distribution, with significant contributions from regions like Asia-Pacific, North America, and Europe. As industries continue to seek materials that offer superior performance and longevity, the demand for niobium carbide is expected to grow, making it a critical area of focus for manufacturers and researchers alike. The market dynamics are influenced by factors such as technological advancements, raw material availability, and regulatory policies, which collectively shape the growth trajectory of the niobium carbide market.

in the Global Niobium Carbide Sales Market:

In the Global Niobium Carbide Sales Market, various types of niobium carbide are utilized by different customers based on their specific needs and applications. One of the primary types is niobium carbide powder, which is widely used in the production of hard metals and cermets. This powder form is favored for its ease of integration into various manufacturing processes, allowing for the creation of components that require high hardness and wear resistance. Customers in the cutting tool industry, for instance, rely on niobium carbide powder to enhance the durability and efficiency of their products. Another type is niobium carbide coatings, which are applied to surfaces to improve their resistance to wear and corrosion. These coatings are particularly popular in the aerospace and automotive industries, where components are subjected to extreme conditions and require additional protection to ensure longevity and performance. Additionally, niobium carbide is available in granule form, which is used in the production of high-temperature structural materials. These granules are essential in applications where materials must withstand extreme heat and pressure, such as in the manufacturing of turbine blades and other critical components in the energy sector. The choice of niobium carbide type is often dictated by the specific requirements of the application, with factors such as particle size, purity, and form playing a crucial role in determining suitability. For instance, in the electronics industry, where precision and purity are paramount, high-purity niobium carbide is preferred to ensure optimal performance and reliability of electronic components. Similarly, in the production of wear-resistant coatings, the particle size of niobium carbide can significantly impact the coating's effectiveness, with finer particles often providing better coverage and adhesion. The market also sees a demand for customized niobium carbide solutions, where manufacturers work closely with customers to develop products that meet their unique specifications. This customization is particularly prevalent in industries with stringent performance requirements, such as defense and aerospace, where even minor deviations in material properties can have significant implications. As the market evolves, there is a growing emphasis on developing new types of niobium carbide that offer enhanced properties and performance. Research and development efforts are focused on improving the material's hardness, thermal stability, and resistance to oxidation, among other attributes. These advancements are expected to open up new applications and expand the market's reach, providing customers with more options to meet their specific needs. Overall, the Global Niobium Carbide Sales Market is characterized by a diverse range of products that cater to the varied demands of different industries, with each type offering unique benefits and applications.

in the Global Niobium Carbide Sales Market:

The Global Niobium Carbide Sales Market finds applications across a wide range of industries, each leveraging the material's unique properties to enhance performance and durability. One of the primary applications is in the manufacturing of cutting tools, where niobium carbide is used to improve the hardness and wear resistance of the tools. This is particularly important in industries such as metalworking and mining, where tools are subjected to intense wear and tear. By incorporating niobium carbide, manufacturers can produce cutting tools that last longer and perform more efficiently, reducing downtime and maintenance costs. Another significant application is in the production of wear-resistant coatings. Niobium carbide coatings are applied to various components to protect them from corrosion and wear, extending their lifespan and maintaining their performance. This is especially valuable in the aerospace and automotive industries, where components are exposed to harsh environments and require additional protection to ensure reliability and safety. In the electronics industry, niobium carbide is used in the production of semiconductors and other electronic components. Its high melting point and thermal stability make it an ideal material for applications that require excellent heat resistance and conductivity. This is crucial in the development of advanced electronic devices that demand high performance and reliability. Additionally, niobium carbide is used in the energy sector, particularly in the production of high-temperature structural materials. These materials are essential in applications such as turbine blades and other components that must withstand extreme heat and pressure. By utilizing niobium carbide, manufacturers can produce materials that offer superior performance and longevity, contributing to the efficiency and reliability of energy systems. The defense industry also benefits from the unique properties of niobium carbide, using it in the production of armor and other protective materials. Its hardness and resistance to impact make it an ideal choice for applications that require enhanced protection and durability. As industries continue to seek materials that offer superior performance and longevity, the demand for niobium carbide is expected to grow, making it a critical area of focus for manufacturers and researchers alike. The versatility of niobium carbide and its ability to enhance the performance of various applications make it an invaluable material in the modern industrial landscape.

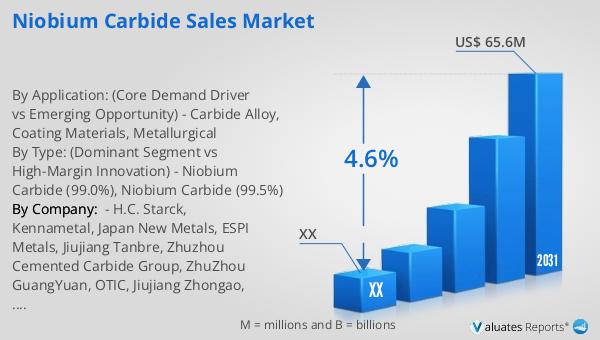

Global Niobium Carbide Sales Market Outlook:

The outlook for the Global Niobium Carbide Market indicates that the market size, which was valued at $48.1 million in 2024, is projected to grow to a revised size of $65.6 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2025 to 2031. The market is dominated by the top three global manufacturers, who collectively hold a market share exceeding 35%. The Asia-Pacific region emerges as the largest production hub, accounting for approximately 40% of the market share, followed by North America and Europe, which together hold about 50% of the market share. Chapter 4 of the market analysis focuses on type-based segmentation, highlighting the potential for discovering untapped markets, such as the demand for Niobium Carbide 99.5% in China. This segmentation analysis is crucial for identifying new opportunities and understanding the diverse needs of different regions and industries. The market dynamics are shaped by factors such as technological advancements, raw material availability, and regulatory policies, which collectively influence the growth trajectory of the niobium carbide market. As industries continue to seek materials that offer superior performance and longevity, the demand for niobium carbide is expected to grow, making it a critical area of focus for manufacturers and researchers alike.

| Report Metric | Details |

| Report Name | Niobium Carbide Sales Market |

| Forecasted market size in 2031 | US$ 65.6 million |

| CAGR | 4.6% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | H.C. Starck, Kennametal, Japan New Metals, ESPI Metals, Jiujiang Tanbre, Zhuzhou Cemented Carbide Group, ZhuZhou GuangYuan, OTIC, Jiujiang Zhongao, Jiangxi King-Tan Tantalum, Changsha Langfeng Metallic Material, WHNM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |