What is Global Multi-Access Laser Micromachining Sales Market?

The Global Multi-Access Laser Micromachining Sales Market is a specialized segment within the broader laser technology industry, focusing on the precision machining of materials using laser technology. This market involves the sale and distribution of laser micromachining systems that are capable of performing intricate and precise cutting, drilling, and engraving tasks on a microscopic scale. These systems are utilized across various industries, including electronics, automotive, aerospace, and medical devices, where high precision and accuracy are paramount. The market is driven by the increasing demand for miniaturized components and devices, which require advanced manufacturing techniques to produce. As industries continue to innovate and develop smaller, more complex products, the need for multi-access laser micromachining systems is expected to grow. These systems offer significant advantages over traditional machining methods, including higher precision, reduced material waste, and the ability to work with a wide range of materials. The market is characterized by rapid technological advancements, with manufacturers continuously developing new and improved systems to meet the evolving needs of their customers. As a result, the Global Multi-Access Laser Micromachining Sales Market is poised for significant growth in the coming years.

in the Global Multi-Access Laser Micromachining Sales Market:

The Global Multi-Access Laser Micromachining Sales Market encompasses a variety of types that cater to the diverse needs of customers across different industries. One of the primary types is the Multi-Axis Low Power Micromachining system, which holds a significant share of the market. These systems are designed for applications that require high precision but do not demand high power output. They are ideal for industries such as electronics and medical devices, where delicate and intricate components are common. Another type is the Multi-Axis High Power Micromachining system, which is used for applications that require more robust machining capabilities. These systems are suitable for industries like aerospace and automotive, where materials are often tougher and require more power to machine effectively. Additionally, there are specialized systems designed for specific applications, such as laser drilling, cutting, and engraving. Each of these systems offers unique features and capabilities, allowing customers to choose the one that best meets their specific needs. The choice of system often depends on factors such as the material being machined, the desired level of precision, and the production volume. For instance, in the electronics industry, where components are becoming increasingly miniaturized, the demand for low power, high precision systems is particularly high. These systems enable manufacturers to produce intricate components with minimal material waste and high repeatability. In contrast, the automotive and aerospace industries often require high power systems capable of machining tougher materials like metals and composites. These industries benefit from the ability to produce complex parts with high structural integrity and precision. Furthermore, advancements in laser technology have led to the development of hybrid systems that combine multiple machining capabilities in a single unit. These systems offer greater flexibility and efficiency, allowing manufacturers to perform a variety of tasks without the need for multiple machines. This versatility is particularly valuable in industries where production requirements can vary significantly. Overall, the Global Multi-Access Laser Micromachining Sales Market offers a wide range of systems to meet the diverse needs of its customers. As technology continues to advance, the capabilities of these systems are expected to expand, further enhancing their appeal to industries seeking precision and efficiency in their manufacturing processes.

in the Global Multi-Access Laser Micromachining Sales Market:

The applications of the Global Multi-Access Laser Micromachining Sales Market are vast and varied, spanning multiple industries that require precision and accuracy in their manufacturing processes. In the electronics industry, laser micromachining is used extensively for the production of microelectronic components, such as semiconductors, printed circuit boards (PCBs), and microelectromechanical systems (MEMS). These components require intricate designs and high precision, which laser micromachining systems can provide. The ability to produce small, complex features with high accuracy makes these systems invaluable in the electronics sector. In the medical industry, laser micromachining is used for the production of medical devices and implants. The precision offered by these systems is crucial for creating components that meet the stringent quality and safety standards required in the medical field. Applications include the production of stents, catheters, and other implantable devices, where precision and biocompatibility are essential. The aerospace industry also benefits from laser micromachining, particularly in the production of lightweight and high-strength components. The ability to machine complex geometries with high precision allows manufacturers to produce parts that meet the demanding performance requirements of the aerospace sector. This includes components for aircraft engines, structural parts, and other critical systems. In the automotive industry, laser micromachining is used for the production of components that require high precision and durability. This includes parts for engines, transmissions, and other critical systems where precision machining is essential for performance and reliability. The ability to produce complex shapes and features with high accuracy is a significant advantage in this industry. Additionally, laser micromachining is used in the production of consumer electronics, where the demand for miniaturized and complex components is high. The precision and flexibility offered by these systems make them ideal for producing components for smartphones, tablets, and other electronic devices. Overall, the applications of the Global Multi-Access Laser Micromachining Sales Market are diverse and continue to expand as industries seek more advanced manufacturing solutions. The precision, efficiency, and versatility of these systems make them an essential tool in modern manufacturing, driving innovation and enabling the production of increasingly complex and high-performance products.

Global Multi-Access Laser Micromachining Sales Market Outlook:

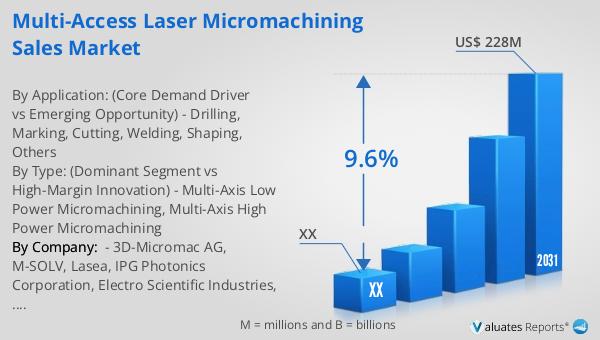

In 2024, the global Multi-Access Laser Micromachining market was valued at approximately $121 million. Projections indicate that by 2031, this market will grow to an adjusted size of around $228 million, reflecting a compound annual growth rate (CAGR) of 9.6% during the forecast period from 2025 to 2031. This growth is indicative of the increasing demand for precision machining solutions across various industries. Notably, the top five manufacturers in this market hold a significant share, accounting for over 80% of the market. This concentration suggests that a few key players dominate the industry, likely due to their advanced technology and established customer bases. Within the product segments, Multi-Axis Low Power Micromachining emerges as the largest, capturing over 75% of the market share. This dominance can be attributed to the widespread application of low power systems in industries that require high precision but not necessarily high power output, such as electronics and medical devices. The market's growth trajectory underscores the importance of laser micromachining technology in modern manufacturing, as industries continue to seek solutions that offer precision, efficiency, and versatility. As the market evolves, it is expected that technological advancements and increased adoption across various sectors will further drive its expansion.

| Report Metric | Details |

| Report Name | Multi-Access Laser Micromachining Sales Market |

| Forecasted market size in 2031 | US$ 228 million |

| CAGR | 9.6% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | 3D-Micromac AG, M-SOLV, Lasea, IPG Photonics Corporation, Electro Scientific Industries, 4JET microtech GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |