What is Global Metal Alloy Powder Core Market?

The Global Metal Alloy Powder Core Market is a specialized segment within the broader materials industry, focusing on the production and application of metal alloy powder cores. These cores are essential components in various electronic and electrical devices, serving as the backbone for inductors, transformers, and other magnetic components. The market is driven by the increasing demand for efficient energy conversion and management solutions across multiple industries, including automotive, renewable energy, and consumer electronics. Metal alloy powder cores are favored for their superior magnetic properties, which include high permeability, low core loss, and excellent thermal stability. These characteristics make them ideal for applications requiring high efficiency and reliability. The market is characterized by continuous innovation, with manufacturers investing in research and development to enhance the performance and cost-effectiveness of these materials. As industries strive for more sustainable and energy-efficient solutions, the demand for metal alloy powder cores is expected to grow, driven by advancements in technology and the increasing adoption of renewable energy sources. The market's growth is also supported by the expansion of the electric vehicle sector and the rising need for advanced electronic devices.

Fe-Si Alloys Powder Core, Fe-Ni Alloys Powder Core, FeSiAl Powder Core, Other in the Global Metal Alloy Powder Core Market:

Fe-Si Alloys Powder Core, Fe-Ni Alloys Powder Core, FeSiAl Powder Core, and other variants play a crucial role in the Global Metal Alloy Powder Core Market. Fe-Si (Iron-Silicon) Alloys Powder Core is widely used due to its excellent magnetic properties, including high saturation magnetization and low core loss. These characteristics make it suitable for applications in transformers and inductors, where efficiency and performance are paramount. The Fe-Si alloy is particularly favored in high-frequency applications, where its ability to minimize energy loss is critical. On the other hand, Fe-Ni (Iron-Nickel) Alloys Powder Core is known for its high permeability and low coercivity, making it ideal for applications requiring precise magnetic control. This type of core is often used in sensitive electronic equipment, where stability and accuracy are essential. FeSiAl (Iron-Silicon-Aluminum) Powder Core combines the benefits of both Fe-Si and Fe-Ni alloys, offering a balanced performance with high saturation magnetization and low core loss. This makes it a versatile choice for a wide range of applications, from power electronics to renewable energy systems. Other metal alloy powder cores, such as those incorporating cobalt or other elements, are designed to meet specific performance requirements, offering tailored solutions for niche applications. These variants are often used in specialized industries, where unique magnetic properties are required to achieve optimal performance. The diversity of metal alloy powder cores available in the market allows manufacturers to select the most appropriate material for their specific needs, ensuring that the final product meets the desired performance criteria. As technology continues to advance, the development of new alloy compositions and manufacturing techniques is expected to further enhance the capabilities of metal alloy powder cores, driving innovation and growth in the market.

Automobile, Photovoltaic Wind Power, Home Appliances, Other in the Global Metal Alloy Powder Core Market:

The Global Metal Alloy Powder Core Market finds extensive usage across various sectors, including the automobile, photovoltaic wind power, home appliances, and other industries. In the automobile industry, metal alloy powder cores are integral to the development of electric vehicles (EVs) and hybrid vehicles. They are used in the manufacturing of inductors and transformers, which are essential for the efficient operation of electric drivetrains and power management systems. The demand for lightweight and energy-efficient components in the automotive sector is driving the adoption of metal alloy powder cores, as they offer superior performance and reliability. In the photovoltaic wind power sector, metal alloy powder cores are used in the design of inverters and transformers, which are critical for converting and managing the energy generated by solar panels and wind turbines. The high efficiency and low energy loss characteristics of these cores make them ideal for renewable energy applications, where maximizing energy output is crucial. In the home appliances sector, metal alloy powder cores are used in a variety of electronic devices, including refrigerators, air conditioners, and washing machines. They help improve the energy efficiency and performance of these appliances, contributing to reduced energy consumption and lower utility bills for consumers. Other industries, such as telecommunications and industrial automation, also benefit from the use of metal alloy powder cores, as they provide reliable and efficient solutions for managing electrical energy. The versatility and adaptability of metal alloy powder cores make them a valuable component in a wide range of applications, supporting the ongoing trend towards energy efficiency and sustainability across multiple industries.

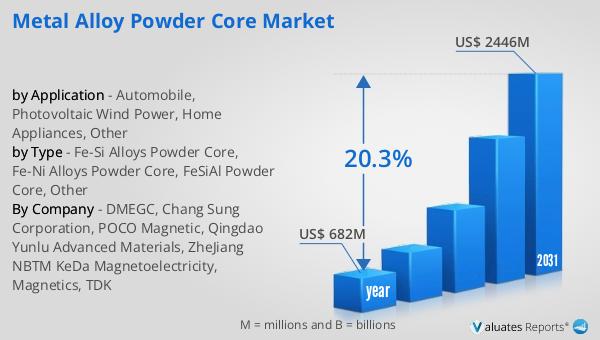

Global Metal Alloy Powder Core Market Outlook:

The global market for Metal Alloy Powder Core was valued at $682 million in 2024 and is anticipated to expand significantly, reaching an estimated $2,446 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 20.3% over the forecast period. The substantial increase in market size is driven by the rising demand for energy-efficient and high-performance materials across various industries. As the world moves towards more sustainable and environmentally friendly solutions, the need for advanced materials like metal alloy powder cores becomes increasingly important. These materials offer superior magnetic properties, making them ideal for applications in renewable energy systems, electric vehicles, and advanced electronic devices. The market's growth is further supported by technological advancements and the increasing adoption of renewable energy sources, which require efficient energy conversion and management solutions. As industries continue to prioritize energy efficiency and sustainability, the demand for metal alloy powder cores is expected to rise, driving market expansion and innovation. The projected growth of the market highlights the importance of metal alloy powder cores in the development of next-generation technologies and their role in supporting the global transition towards a more sustainable future.

| Report Metric | Details |

| Report Name | Metal Alloy Powder Core Market |

| Accounted market size in year | US$ 682 million |

| Forecasted market size in 2031 | US$ 2446 million |

| CAGR | 20.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DMEGC, Chang Sung Corporation, POCO Magnetic, Qingdao Yunlu Advanced Materials, ZheJiang NBTM KeDa Magnetoelectricity, Magnetics, TDK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |