What is Global Medical Micro Machining Market?

The Global Medical Micro Machining Market is a specialized sector within the broader medical device industry, focusing on the production of extremely small and precise components used in medical applications. This market is driven by the increasing demand for miniaturized medical devices that offer enhanced performance, reliability, and patient comfort. Micro machining technologies enable the fabrication of intricate parts with high precision, which is essential for the development of advanced medical devices. These technologies include laser micro machining, micro CNC machining, micro electrical discharge machining, micro injection molding, and micro 3D printing. Each of these techniques offers unique advantages in terms of precision, material compatibility, and production efficiency. The market is characterized by continuous innovation and technological advancements, as manufacturers strive to meet the evolving needs of the healthcare industry. The growing prevalence of chronic diseases, an aging population, and the increasing adoption of minimally invasive surgical procedures are key factors driving the demand for micro machined medical components. As a result, the Global Medical Micro Machining Market is poised for significant growth, offering numerous opportunities for companies operating in this space.

Laser Micro Machining, Micro CNC Machining, Micro Electrical Discharge Machining, Micro Injection Molding, Micro 3D Printing in the Global Medical Micro Machining Market:

Laser micro machining is a pivotal technology in the Global Medical Micro Machining Market, known for its ability to produce highly precise and intricate components. This technique uses focused laser beams to cut, drill, or engrave materials with exceptional accuracy, making it ideal for creating complex geometries required in medical devices. The precision of laser micro machining allows for the production of components with tight tolerances, which is crucial for ensuring the reliability and performance of medical devices. Additionally, this method is versatile, capable of working with a wide range of materials, including metals, polymers, and ceramics. Micro CNC machining, on the other hand, involves the use of computer-controlled machines to fabricate small parts with high precision. This technique is particularly useful for producing components with complex shapes and features, as it allows for precise control over the machining process. Micro CNC machining is widely used in the production of surgical instruments, implants, and other medical devices that require intricate designs. Micro electrical discharge machining (EDM) is another important technology in this market, known for its ability to machine hard and brittle materials with high precision. This technique uses electrical discharges to erode material from the workpiece, allowing for the creation of complex shapes and fine details. Micro EDM is particularly useful for machining materials that are difficult to process using traditional methods, such as tungsten and titanium. Micro injection molding is a process used to produce small, intricate plastic components with high precision. This technique involves injecting molten plastic into a mold cavity, where it cools and solidifies to form the desired shape. Micro injection molding is widely used in the production of medical devices such as catheters, syringes, and other disposable components. Finally, micro 3D printing is an emerging technology that offers the ability to create complex, customized components with high precision. This technique involves the layer-by-layer deposition of material to build up a three-dimensional object, allowing for the creation of intricate geometries that would be difficult or impossible to achieve using traditional methods. Micro 3D printing is particularly useful for producing prototypes and small-batch production runs, as it allows for rapid iteration and customization. Overall, these micro machining technologies play a crucial role in the Global Medical Micro Machining Market, enabling the production of advanced medical devices that meet the stringent requirements of the healthcare industry.

Medical Implants, Microfluidics, Surgical Instruments, Catheters & Guidewires in the Global Medical Micro Machining Market:

The Global Medical Micro Machining Market finds extensive applications in various areas, including medical implants, microfluidics, surgical instruments, and catheters & guidewires. In the realm of medical implants, micro machining technologies are used to produce components with high precision and intricate designs, which are essential for ensuring the functionality and biocompatibility of implants. For instance, micro CNC machining and laser micro machining are commonly used to fabricate components for orthopedic implants, dental implants, and cardiovascular stents. These technologies enable the production of implants with complex geometries and tight tolerances, which are crucial for ensuring proper fit and function within the human body. In the field of microfluidics, micro machining technologies are used to create small, precise channels and structures that are essential for the manipulation of fluids at the microscale. Microfluidic devices are used in a wide range of medical applications, including diagnostics, drug delivery, and lab-on-a-chip systems. Techniques such as micro injection molding and micro 3D printing are particularly useful for producing microfluidic devices, as they allow for the creation of complex, customized designs with high precision. Surgical instruments are another key area of application for the Global Medical Micro Machining Market. Micro machining technologies are used to produce instruments with intricate designs and high precision, which are essential for ensuring the performance and reliability of surgical tools. Techniques such as micro CNC machining and micro EDM are commonly used to fabricate components for surgical instruments, as they allow for the creation of complex shapes and fine details. Finally, in the area of catheters & guidewires, micro machining technologies are used to produce components with high precision and intricate designs, which are essential for ensuring the functionality and performance of these devices. Techniques such as laser micro machining and micro injection molding are commonly used to fabricate components for catheters and guidewires, as they allow for the creation of complex geometries and tight tolerances. Overall, the Global Medical Micro Machining Market plays a crucial role in the production of advanced medical devices that meet the stringent requirements of the healthcare industry.

Global Medical Micro Machining Market Outlook:

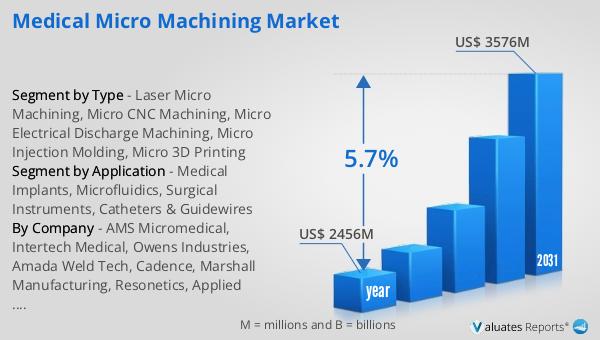

In 2024, the global market for Medical Micro Machining was valued at approximately $2,456 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach an estimated size of $3,576 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.7% throughout the forecast period. The expansion of this market can be attributed to several factors, including the increasing demand for miniaturized medical devices, advancements in micro machining technologies, and the growing prevalence of chronic diseases that necessitate advanced medical solutions. As the healthcare industry continues to evolve, the need for precise and reliable medical components becomes increasingly critical, driving the demand for micro machining technologies. Companies operating in this market are likely to benefit from the ongoing innovation and technological advancements, as they strive to meet the evolving needs of the healthcare sector. The projected growth of the Global Medical Micro Machining Market underscores the importance of these technologies in the development of advanced medical devices, offering numerous opportunities for businesses to capitalize on this expanding market.

| Report Metric | Details |

| Report Name | Medical Micro Machining Market |

| Accounted market size in year | US$ 2456 million |

| Forecasted market size in 2031 | US$ 3576 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | AMS Micromedical, Intertech Medical, Owens Industries, Amada Weld Tech, Cadence, Marshall Manufacturing, Resonetics, Applied Medical, Swiss Precision Machining, Mack Molding, EnvisionTEC, Acrotec Medtech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |