What is Global Magnetic Powder Clutch Market?

The Global Magnetic Powder Clutch Market is a specialized segment within the broader mechanical and industrial equipment industry. Magnetic powder clutches are devices that use magnetic powder to transmit torque between an input and an output shaft. These clutches are known for their precise control and smooth operation, making them ideal for applications requiring variable torque and speed control. The market for these clutches is driven by their widespread use in various industries, including automotive, packaging, printing, and textiles, where they are used to control tension and speed in machinery. The demand for magnetic powder clutches is also influenced by the growing need for automation and efficient machinery in manufacturing processes. As industries continue to seek ways to improve productivity and reduce downtime, the adoption of magnetic powder clutches is expected to rise. Additionally, advancements in technology and materials are leading to the development of more efficient and durable clutches, further fueling market growth. The market is characterized by a mix of established players and new entrants, all competing to offer innovative solutions to meet the evolving needs of their customers.

Dual Shaft Magnetic Powder Clutch, Single Shaft Magnetic Powder Clutch, Hollow Shaft Magnetic Powder Clutch in the Global Magnetic Powder Clutch Market:

In the Global Magnetic Powder Clutch Market, there are several types of clutches, each designed to meet specific application requirements. The Dual Shaft Magnetic Powder Clutch is one of the most common types, known for its ability to handle high torque loads while maintaining precise control. This type of clutch is typically used in applications where two shafts need to be synchronized, such as in printing presses or conveyor systems. The dual shaft design allows for smooth and efficient power transmission, reducing wear and tear on machinery and extending the lifespan of equipment. On the other hand, the Single Shaft Magnetic Powder Clutch is designed for applications where only one shaft requires torque control. This type of clutch is often used in machinery where space is limited, as it is more compact than its dual shaft counterpart. Despite its smaller size, the single shaft clutch offers excellent performance and reliability, making it a popular choice in industries such as packaging and textiles. Lastly, the Hollow Shaft Magnetic Powder Clutch is designed for applications where weight and space are critical factors. The hollow shaft design reduces the overall weight of the clutch, making it ideal for use in lightweight machinery or equipment with limited space. This type of clutch is often used in robotics and other high-tech applications where precision and efficiency are paramount. Each of these clutches offers unique advantages, and the choice of which to use depends on the specific needs of the application. Manufacturers in the Global Magnetic Powder Clutch Market continue to innovate and improve these products, ensuring they meet the ever-changing demands of their customers.

Mechanical Equipment, Test Equipment, Other Equipment in the Global Magnetic Powder Clutch Market:

The Global Magnetic Powder Clutch Market finds extensive usage across various sectors, particularly in mechanical equipment, test equipment, and other specialized machinery. In the realm of mechanical equipment, magnetic powder clutches are integral to the operation of machines that require precise control over torque and speed. For instance, in the automotive industry, these clutches are used in dynamometers to test engine performance by simulating different driving conditions. They allow for smooth transitions and accurate measurements, which are crucial for developing efficient and reliable vehicles. Similarly, in the packaging industry, magnetic powder clutches help maintain consistent tension in wrapping and labeling machines, ensuring high-quality output and reducing material waste. In test equipment, magnetic powder clutches are essential for applications that demand high precision and repeatability. They are often used in testing rigs for motors and gearboxes, where they provide controlled resistance to simulate real-world operating conditions. This capability is vital for manufacturers looking to validate the performance and durability of their products before they reach the market. Additionally, in the field of robotics, magnetic powder clutches enable precise movement control, which is critical for tasks that require high accuracy and repeatability. Beyond these applications, magnetic powder clutches are also used in other specialized equipment, such as printing presses and textile machinery. In printing, they help control the tension of paper or other materials as they pass through the press, ensuring sharp and clear prints. In textiles, they are used to regulate the tension of threads and fabrics, which is essential for producing high-quality garments and textiles. The versatility and reliability of magnetic powder clutches make them a valuable component in a wide range of industries, driving their demand in the global market.

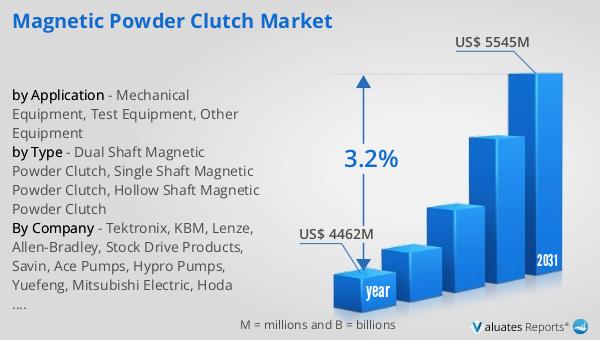

Global Magnetic Powder Clutch Market Outlook:

The global market for Magnetic Powder Clutch was valued at approximately $4,462 million in 2024. It is anticipated to expand to a revised size of around $5,545 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.2% over the forecast period. This growth trajectory underscores the increasing demand for magnetic powder clutches across various industries, driven by the need for precise torque control and efficient machinery operation. As industries continue to evolve and seek more advanced solutions for their mechanical and automation needs, the role of magnetic powder clutches becomes increasingly significant. The steady growth rate also indicates a stable market environment, where both established players and new entrants can find opportunities for innovation and expansion. The projected market size by 2031 highlights the potential for continued investment and development in this sector, as manufacturers strive to meet the diverse and changing needs of their customers. With advancements in technology and materials, the magnetic powder clutch market is poised for sustained growth, offering numerous opportunities for businesses to capitalize on the increasing demand for high-performance and reliable clutch solutions.

| Report Metric | Details |

| Report Name | Magnetic Powder Clutch Market |

| Accounted market size in year | US$ 4462 million |

| Forecasted market size in 2031 | US$ 5545 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tektronix, KBM, Lenze, Allen-Bradley, Stock Drive Products, Savin, Ace Pumps, Hypro Pumps, Yuefeng, Mitsubishi Electric, Hoda Electromechanical, STANNO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |