What is Global Magnetic Alloy Powder Market?

The Global Magnetic Alloy Powder Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries. Magnetic alloy powders are finely milled materials composed of magnetic metals and alloys, which exhibit magnetic properties. These powders are essential in the production of magnetic components used in a wide range of applications, from electronics to automotive industries. The market for these powders is driven by the increasing demand for efficient and compact magnetic components, which are integral to modern technology. As industries continue to innovate and seek more efficient solutions, the demand for high-performance magnetic alloy powders is expected to grow. These powders are not only used in traditional applications but are also finding new uses in emerging technologies, making them a vital component of the global industrial landscape. The market is characterized by a diverse range of products, each tailored to specific applications, and is supported by ongoing research and development efforts aimed at enhancing the performance and efficiency of magnetic materials. As a result, the Global Magnetic Alloy Powder Market is poised for significant growth, driven by technological advancements and the increasing need for sustainable and efficient energy solutions.

Fe-Si Alloys, Fe-Ni Alloys, Fe-Co Alloys, Fe-Cr Alloys, Pure Iron in the Global Magnetic Alloy Powder Market:

Fe-Si alloys, Fe-Ni alloys, Fe-Co alloys, Fe-Cr alloys, and pure iron are key components of the Global Magnetic Alloy Powder Market, each offering unique properties and applications. Fe-Si alloys, or iron-silicon alloys, are known for their excellent magnetic permeability and low core loss, making them ideal for use in transformers, inductors, and other electrical devices. These alloys are particularly valued for their ability to enhance energy efficiency in electrical systems. Fe-Ni alloys, also known as permalloys, are characterized by their high magnetic permeability and low coercivity, which makes them suitable for applications requiring precise magnetic field control, such as in magnetic shielding and sensors. Fe-Co alloys, or iron-cobalt alloys, are renowned for their high saturation magnetization and Curie temperature, making them suitable for high-performance applications in aerospace and defense industries. These alloys are often used in the production of high-speed motors and generators. Fe-Cr alloys, or iron-chromium alloys, offer excellent corrosion resistance and are used in applications where durability and longevity are critical, such as in harsh industrial environments. Pure iron, while not an alloy, is also a significant component of the magnetic alloy powder market due to its high magnetic permeability and low coercivity. It is often used in applications where high magnetic performance is required, such as in electromagnets and magnetic cores. Each of these materials plays a vital role in the development of advanced magnetic components, contributing to the growth and diversification of the Global Magnetic Alloy Powder Market. The ongoing research and development efforts in this field are focused on enhancing the properties of these materials to meet the evolving demands of various industries, ensuring that they remain at the forefront of technological innovation.

Automobile, Photovoltaic Wind Power, Home Appliances, Computers and Office Equipment, Communications, Industrial and Medical Instruments, Other in the Global Magnetic Alloy Powder Market:

The Global Magnetic Alloy Powder Market finds extensive usage across a variety of sectors, each benefiting from the unique properties of magnetic alloy powders. In the automobile industry, these powders are used in the production of electric motors, sensors, and other components that require precise magnetic properties. The demand for electric vehicles and advanced automotive technologies is driving the need for high-performance magnetic materials that can enhance energy efficiency and performance. In the photovoltaic and wind power sectors, magnetic alloy powders are used in the production of generators and transformers, which are essential for converting and distributing renewable energy. The push for sustainable energy solutions is increasing the demand for efficient magnetic components that can improve the performance and reliability of renewable energy systems. In the realm of home appliances, magnetic alloy powders are used in motors and sensors that power a wide range of devices, from refrigerators to washing machines. These materials help improve the energy efficiency and performance of household appliances, contributing to energy conservation efforts. In computers and office equipment, magnetic alloy powders are used in hard drives, printers, and other devices that require precise magnetic control. The demand for faster and more efficient computing solutions is driving the need for advanced magnetic materials that can enhance data storage and processing capabilities. In the communications sector, magnetic alloy powders are used in the production of antennas, filters, and other components that require precise magnetic properties. The increasing demand for high-speed and reliable communication networks is driving the need for advanced magnetic materials that can enhance signal quality and transmission efficiency. In industrial and medical instruments, magnetic alloy powders are used in the production of sensors, actuators, and other components that require precise magnetic control. These materials are essential for the development of advanced diagnostic and therapeutic devices that can improve patient outcomes and enhance industrial processes. Other applications of magnetic alloy powders include their use in consumer electronics, aerospace, and defense industries, where they are used in the production of high-performance components that require precise magnetic properties. The versatility and performance of magnetic alloy powders make them a critical component of modern technology, driving their demand across a wide range of industries.

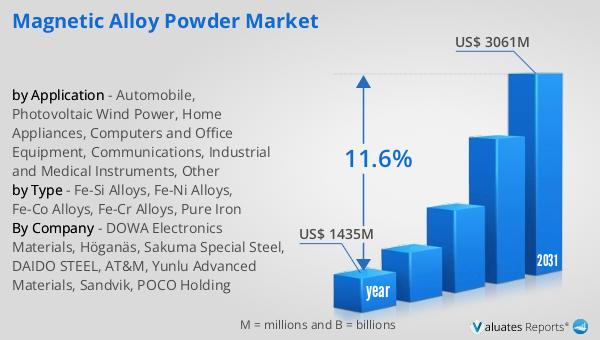

Global Magnetic Alloy Powder Market Outlook:

The global market for Magnetic Alloy Powder, valued at approximately $1,435 million in 2024, is on a trajectory to reach an estimated $3,061 million by 2031. This growth represents a compound annual growth rate (CAGR) of 11.6% over the forecast period. This significant expansion underscores the increasing demand for magnetic alloy powders across various industries, driven by technological advancements and the need for efficient and sustainable solutions. As industries continue to innovate and seek more efficient solutions, the demand for high-performance magnetic alloy powders is expected to grow. The market is characterized by a diverse range of products, each tailored to specific applications, and is supported by ongoing research and development efforts aimed at enhancing the performance and efficiency of magnetic materials. The ongoing research and development efforts in this field are focused on enhancing the properties of these materials to meet the evolving demands of various industries, ensuring that they remain at the forefront of technological innovation. The versatility and performance of magnetic alloy powders make them a critical component of modern technology, driving their demand across a wide range of industries.

| Report Metric | Details |

| Report Name | Magnetic Alloy Powder Market |

| Accounted market size in year | US$ 1435 million |

| Forecasted market size in 2031 | US$ 3061 million |

| CAGR | 11.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DOWA Electronics Materials, Höganäs, Sakuma Special Steel, DAIDO STEEL, AT&M, Yunlu Advanced Materials, Sandvik, POCO Holding |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |