What is Global Laboratory Grinding Machine Market?

The Global Laboratory Grinding Machine Market is a specialized segment within the broader machinery industry, focusing on devices used to grind and pulverize materials in laboratory settings. These machines are essential for preparing samples for analysis, ensuring that materials are reduced to a fine consistency suitable for testing. Laboratories across various sectors, including pharmaceuticals, agriculture, and chemicals, rely on these machines to ensure precision and accuracy in their research and development processes. The market encompasses a range of grinding machines, each designed to handle specific types of materials and grinding requirements. As industries continue to advance and the demand for high-quality, reliable laboratory equipment grows, the market for laboratory grinding machines is expected to expand. This growth is driven by technological advancements, increased research activities, and the need for efficient sample preparation methods. The market is characterized by a diverse range of products, including ball mills, disc mills, rotor mills, and cutting mills, each offering unique features and benefits to meet the varied needs of laboratory professionals. As a result, the Global Laboratory Grinding Machine Market plays a crucial role in supporting scientific research and innovation across multiple industries.

Ball Mills, Disc Mills, Rotor Mills, Cutting Mills, Others in the Global Laboratory Grinding Machine Market:

Ball mills are a cornerstone of the Global Laboratory Grinding Machine Market, known for their versatility and efficiency in grinding a wide range of materials. These machines operate by rotating a cylinder filled with grinding media, such as balls, which crush and grind the material inside. Ball mills are particularly effective for grinding hard and brittle materials, making them ideal for use in laboratories that require precise particle size reduction. Their ability to handle both wet and dry grinding processes adds to their appeal, allowing for flexibility in sample preparation. Disc mills, on the other hand, utilize a pair of grinding discs to achieve size reduction. The material is fed between the discs, which rotate in opposite directions, creating a shearing action that grinds the material to the desired size. Disc mills are favored for their ability to produce uniform particle sizes and are commonly used in applications where consistency is critical. Rotor mills are another type of laboratory grinding machine, characterized by their high-speed rotors that generate impact and shear forces to pulverize materials. These machines are particularly effective for grinding soft to medium-hard materials and are often used in applications where rapid sample processing is required. Cutting mills, as the name suggests, use sharp blades to cut and grind materials. They are ideal for processing fibrous and tough materials, such as plastics and textiles, and are commonly used in laboratories that deal with heterogeneous samples. Each type of grinding machine offers distinct advantages, allowing laboratories to choose the most suitable equipment for their specific needs. The diversity of machines available in the Global Laboratory Grinding Machine Market ensures that laboratories can find the right solution for their grinding requirements, whether they need to process small or large volumes of material, achieve specific particle sizes, or handle challenging sample types. As technology continues to evolve, these machines are becoming more sophisticated, offering enhanced features such as digital controls, automated sample handling, and improved safety mechanisms. This ongoing innovation is driving the growth of the market, as laboratories seek out advanced equipment that can improve efficiency, accuracy, and reliability in their research processes.

Bio & Pharmaceutical, Agriculture & Food, Chemical Material, Other in the Global Laboratory Grinding Machine Market:

The Global Laboratory Grinding Machine Market finds extensive usage across various sectors, including bio & pharmaceutical, agriculture & food, chemical material, and others. In the bio & pharmaceutical industry, these machines are crucial for preparing samples for drug development and testing. The ability to achieve precise particle sizes is essential for ensuring the efficacy and safety of pharmaceutical products. Laboratory grinding machines enable researchers to process active pharmaceutical ingredients and excipients, facilitating the development of new drugs and formulations. In the agriculture & food sector, these machines are used to grind and analyze samples of crops, soil, and food products. Accurate sample preparation is vital for assessing the nutritional content, quality, and safety of agricultural and food products. Grinding machines help researchers and quality control professionals obtain consistent and reliable results, supporting efforts to improve crop yields, enhance food safety, and develop new food products. The chemical material industry also relies heavily on laboratory grinding machines for sample preparation. These machines are used to grind raw materials, intermediates, and finished products, enabling researchers to analyze chemical compositions, study reactions, and develop new materials. The ability to achieve uniform particle sizes is critical for ensuring the accuracy and reproducibility of chemical analyses. Beyond these primary sectors, laboratory grinding machines are used in a variety of other applications, including environmental testing, materials science, and forensic analysis. In environmental testing, these machines are used to prepare samples of soil, water, and air for analysis, helping researchers assess pollution levels and study environmental impacts. In materials science, grinding machines are used to prepare samples for microscopy and other analytical techniques, enabling researchers to study the properties and behavior of materials at the micro and nanoscale. In forensic analysis, these machines are used to prepare samples of evidence for examination, supporting efforts to solve crimes and ensure justice. The versatility and reliability of laboratory grinding machines make them indispensable tools in a wide range of scientific and industrial applications, driving demand and growth in the Global Laboratory Grinding Machine Market.

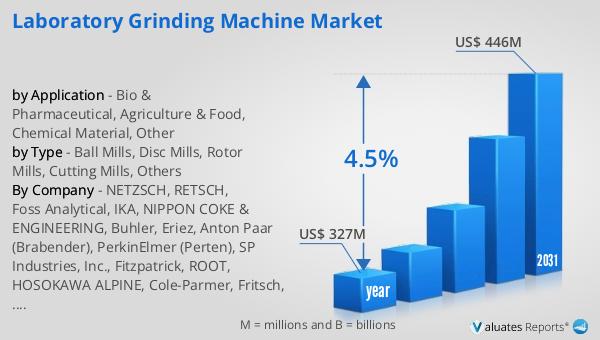

Global Laboratory Grinding Machine Market Outlook:

The global market for laboratory grinding machines was valued at $327 million in 2024 and is anticipated to grow to a revised size of $446 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period. Ball mills are the dominant force in this market, accounting for a significant share of approximately 34% of the global market. This dominance is attributed to their versatility and efficiency in handling a wide range of materials, making them a preferred choice for many laboratories. The Asia-Pacific region emerges as the largest consumer market for these devices, contributing around 36% of the global market. This prominence is driven by the rapid industrialization and technological advancements occurring in the region, which have increased the demand for high-quality laboratory equipment. The growth in this region is further supported by the expanding research and development activities across various industries, including pharmaceuticals, agriculture, and chemicals. As laboratories continue to seek advanced equipment that can enhance their research capabilities, the demand for laboratory grinding machines is expected to rise, fueling market growth. The ongoing innovation in grinding machine technology, coupled with the increasing need for efficient sample preparation methods, is likely to drive further expansion of the Global Laboratory Grinding Machine Market in the coming years.

| Report Metric | Details |

| Report Name | Laboratory Grinding Machine Market |

| Accounted market size in year | US$ 327 million |

| Forecasted market size in 2031 | US$ 446 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NETZSCH, RETSCH, Foss Analytical, IKA, NIPPON COKE & ENGINEERING, Buhler, Eriez, Anton Paar (Brabender), PerkinElmer (Perten), SP Industries, Inc., Fitzpatrick, ROOT, HOSOKAWA ALPINE, Cole-Parmer, Fritsch, SIEBTECHNIK GMBH, Ortoalresa, SIEHE, Malvern Panalytical, Kinematica, RUCCA, VIBROTECHNIK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |