What is Global Intermediate Shaping Machine Market?

The Global Intermediate Shaping Machine Market is a specialized segment within the broader machinery industry, focusing on machines designed to shape materials into intermediate forms. These machines are crucial in various manufacturing processes, providing precision and efficiency in shaping materials such as metals, plastics, and composites. The market encompasses a range of machines that cater to different industrial needs, from small-scale operations to large manufacturing plants. These machines are integral in producing components that require specific shapes and dimensions, serving industries such as automotive, aerospace, electronics, and more. The demand for intermediate shaping machines is driven by the need for high-quality, precision-engineered components that meet stringent industry standards. As industries continue to evolve and demand more complex and precise components, the role of intermediate shaping machines becomes increasingly important. The market is characterized by technological advancements, with manufacturers continually innovating to improve machine performance, efficiency, and versatility. This ongoing innovation ensures that the Global Intermediate Shaping Machine Market remains dynamic and responsive to the changing needs of various industries. The market's growth is also supported by the increasing adoption of automation and digital technologies, which enhance the capabilities and efficiency of shaping machines.

Vertical, Horizontal in the Global Intermediate Shaping Machine Market:

In the Global Intermediate Shaping Machine Market, machines are primarily categorized into vertical and horizontal configurations, each offering distinct advantages and applications. Vertical shaping machines are designed with a vertical spindle orientation, making them ideal for tasks that require precision and stability. These machines are often used in applications where the workpiece needs to be held in place securely, such as in the production of intricate components for the aerospace and automotive industries. The vertical design allows for better control over the shaping process, reducing the risk of errors and ensuring high-quality output. Additionally, vertical shaping machines are known for their compact design, making them suitable for facilities with limited space. On the other hand, horizontal shaping machines feature a horizontal spindle orientation, which is advantageous for handling larger and heavier workpieces. These machines are commonly used in industries that require the shaping of large components, such as in the construction and heavy machinery sectors. The horizontal design provides better support for the workpiece, allowing for more efficient material removal and shaping. This configuration is particularly beneficial for tasks that involve long or bulky materials, as it minimizes the risk of deflection and ensures consistent results. Both vertical and horizontal shaping machines are equipped with advanced features that enhance their performance and versatility. For instance, many modern machines come with computer numerical control (CNC) systems, which allow for precise control over the shaping process. This technology enables manufacturers to produce complex shapes with high accuracy, reducing waste and improving overall efficiency. Furthermore, the integration of automation and digital technologies in shaping machines has revolutionized the manufacturing process, allowing for greater flexibility and customization. Manufacturers can now easily switch between different shaping tasks, adapting to changing production needs without significant downtime. This adaptability is crucial in today's fast-paced industrial environment, where the ability to respond quickly to market demands is a key competitive advantage. The choice between vertical and horizontal shaping machines ultimately depends on the specific requirements of the application. Factors such as the size and weight of the workpiece, the desired level of precision, and the available space in the facility all play a role in determining the most suitable machine configuration. As the Global Intermediate Shaping Machine Market continues to grow, manufacturers are likely to see an increasing demand for both vertical and horizontal machines, driven by the diverse needs of various industries. The ongoing development of new technologies and materials will further expand the capabilities of these machines, opening up new possibilities for innovation and efficiency in the shaping process.

Automotive, Home Appliances, Mechanical Equipment, Robot, Others in the Global Intermediate Shaping Machine Market:

The Global Intermediate Shaping Machine Market plays a vital role in several key industries, including automotive, home appliances, mechanical equipment, robotics, and others. In the automotive industry, shaping machines are essential for producing components that require high precision and durability. These machines are used to shape parts such as engine components, transmission parts, and body panels, ensuring they meet the stringent quality standards required for automotive applications. The ability to produce complex shapes with high accuracy is crucial in this industry, where even minor deviations can impact the performance and safety of vehicles. In the home appliances sector, intermediate shaping machines are used to manufacture components for products such as refrigerators, washing machines, and air conditioners. These machines enable manufacturers to produce parts with the exact specifications needed to ensure the proper functioning and longevity of appliances. The demand for energy-efficient and reliable home appliances has driven the need for high-quality components, further boosting the market for shaping machines. In the field of mechanical equipment, shaping machines are used to produce a wide range of components, from gears and shafts to brackets and housings. These machines provide the precision and consistency needed to ensure that mechanical equipment operates smoothly and efficiently. The ability to produce components with tight tolerances is particularly important in this industry, where the performance and reliability of equipment are critical. In the robotics industry, shaping machines are used to manufacture components for robotic arms, joints, and other parts. The precision and accuracy offered by these machines are essential for producing components that meet the exacting standards required for robotic applications. As the demand for automation and robotics continues to grow, the need for high-quality shaping machines is expected to increase. Beyond these industries, intermediate shaping machines are also used in various other sectors, including aerospace, electronics, and medical devices. In each of these areas, the ability to produce components with high precision and consistency is crucial for meeting industry standards and ensuring the performance and reliability of products. The versatility and adaptability of shaping machines make them an indispensable tool in modern manufacturing, enabling companies to produce high-quality components that meet the diverse needs of their customers.

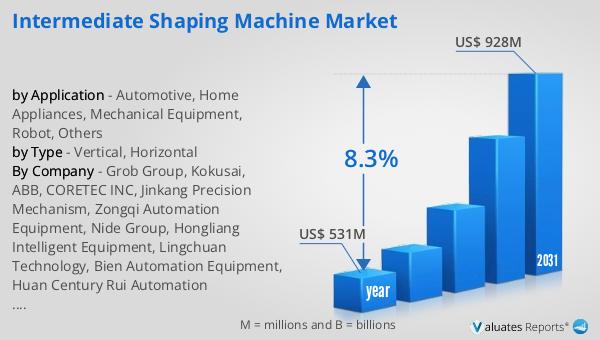

Global Intermediate Shaping Machine Market Outlook:

The outlook for the Global Intermediate Shaping Machine Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $531 million, reflecting its significant role in various industries. Looking ahead, the market is projected to expand substantially, reaching an estimated value of $928 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 8.3% over the forecast period. This upward trend underscores the increasing demand for intermediate shaping machines across different sectors, driven by the need for precision-engineered components and the adoption of advanced manufacturing technologies. The market's expansion is supported by several factors, including technological advancements, the rise of automation, and the growing emphasis on quality and efficiency in manufacturing processes. As industries continue to evolve and require more complex and precise components, the demand for shaping machines is likely to increase. This growth presents significant opportunities for manufacturers and suppliers in the market, as they strive to meet the evolving needs of their customers. The projected growth of the Global Intermediate Shaping Machine Market highlights its importance in modern manufacturing and its potential for continued expansion in the coming years.

| Report Metric | Details |

| Report Name | Intermediate Shaping Machine Market |

| Accounted market size in year | US$ 531 million |

| Forecasted market size in 2031 | US$ 928 million |

| CAGR | 8.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Grob Group, Kokusai, ABB, CORETEC INC, Jinkang Precision Mechanism, Zongqi Automation Equipment, Nide Group, Hongliang Intelligent Equipment, Lingchuan Technology, Bien Automation Equipment, Huan Century Rui Automation Equipment, Hongdian Automation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |