What is Global Industrial Self-Regulating Heat Trace Cables Market?

The Global Industrial Self-Regulating Heat Trace Cables Market is a specialized segment within the broader electrical and thermal management industry. These cables are designed to regulate their heat output in response to changes in ambient temperature, making them highly efficient for maintaining consistent temperatures in various industrial applications. Unlike traditional heating cables, self-regulating heat trace cables adjust their power output automatically, reducing the risk of overheating and conserving energy. This technology is particularly valuable in industries where precise temperature control is crucial, such as in the prevention of pipe freezing, maintaining process temperatures, and ensuring the safe operation of equipment in cold environments. The market for these cables is driven by the increasing demand for energy-efficient solutions and the need for reliable temperature maintenance systems in industries like oil and gas, chemicals, and power generation. As industries continue to prioritize energy efficiency and operational safety, the demand for self-regulating heat trace cables is expected to grow, making this market a vital component of modern industrial infrastructure.

Low Temperature: Up to 80 °C, Medium Temperature: Up to 110 °C, High Temperature: Up to 250 °C in the Global Industrial Self-Regulating Heat Trace Cables Market:

In the Global Industrial Self-Regulating Heat Trace Cables Market, temperature classifications are crucial for understanding the applications and limitations of these cables. The low-temperature category, which includes cables that can handle temperatures up to 80°C, is typically used in applications where minimal heat is required to prevent freezing or maintain a stable temperature. These cables are ideal for residential and light commercial applications, such as maintaining the temperature of water pipes or small tanks. The medium-temperature category, with a threshold of up to 110°C, is suited for more demanding industrial applications. These cables are often used in environments where moderate heat is necessary to maintain process temperatures or prevent condensation in pipes and vessels. They are commonly found in industries like food processing, where maintaining specific temperatures is essential for product quality and safety. The high-temperature category, capable of withstanding temperatures up to 250°C, is designed for the most demanding industrial applications. These cables are used in environments where high heat is necessary, such as in petrochemical plants, refineries, and other heavy industrial settings. They are essential for maintaining the integrity of processes that require high temperatures and for ensuring the safe operation of equipment in extreme conditions. The ability of self-regulating heat trace cables to adjust their heat output based on ambient conditions makes them an invaluable tool in these high-temperature applications, as they provide both safety and efficiency. Overall, the classification of these cables by temperature range allows industries to select the appropriate solution for their specific needs, ensuring optimal performance and safety across a wide range of applications.

Petroleum, Chemical Industry, Electricity, Medicine, Ships, Other in the Global Industrial Self-Regulating Heat Trace Cables Market:

The Global Industrial Self-Regulating Heat Trace Cables Market finds extensive usage across various sectors, each with unique requirements and challenges. In the petroleum industry, these cables are crucial for maintaining the flow of oil and gas in pipelines, especially in cold climates where the risk of freezing is high. By ensuring that the temperature of the pipelines remains above the freezing point, self-regulating heat trace cables help prevent blockages and maintain the efficiency of the transportation process. In the chemical industry, precise temperature control is essential for maintaining the integrity of chemical reactions and processes. Self-regulating heat trace cables provide the necessary temperature stability, ensuring that reactions occur under optimal conditions and that the quality of the final product is maintained. The electricity sector also benefits from these cables, particularly in power plants where they are used to maintain the temperature of critical equipment and prevent the formation of ice on power lines. In the field of medicine, self-regulating heat trace cables are used to maintain the temperature of sensitive medical equipment and supplies, ensuring their efficacy and safety. On ships, these cables are used to prevent the freezing of pipes and equipment, ensuring the smooth operation of the vessel even in harsh maritime environments. Other industries, such as food processing and manufacturing, also rely on self-regulating heat trace cables to maintain process temperatures and ensure product quality. The versatility and efficiency of these cables make them an essential component in a wide range of industrial applications, providing reliable temperature control and energy savings.

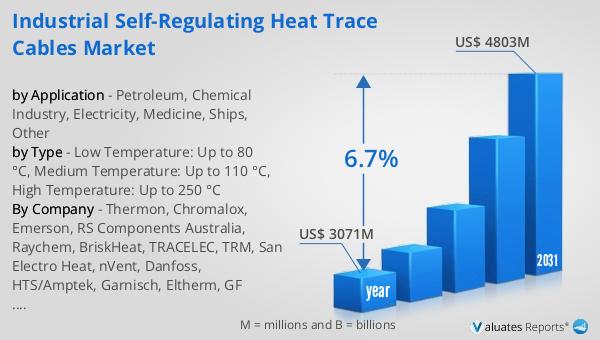

Global Industrial Self-Regulating Heat Trace Cables Market Outlook:

The global market for Industrial Self-Regulating Heat Trace Cables was valued at approximately $3,071 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $4,803 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.7% over the forecast period. The increasing demand for energy-efficient and reliable temperature maintenance solutions across various industries is a key driver of this market growth. As industries continue to prioritize operational efficiency and safety, the adoption of self-regulating heat trace cables is expected to rise. These cables offer significant advantages over traditional heating solutions, including energy savings, reduced risk of overheating, and enhanced safety. The ability of these cables to automatically adjust their heat output in response to changes in ambient temperature makes them an attractive option for industries seeking to optimize their thermal management systems. As a result, the market for self-regulating heat trace cables is poised for substantial growth, driven by the increasing need for efficient and reliable temperature control solutions in a wide range of industrial applications.

| Report Metric | Details |

| Report Name | Industrial Self-Regulating Heat Trace Cables Market |

| Accounted market size in year | US$ 3071 million |

| Forecasted market size in 2031 | US$ 4803 million |

| CAGR | 6.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Thermon, Chromalox, Emerson, RS Components Australia, Raychem, BriskHeat, TRACELEC, TRM, San Electro Heat, nVent, Danfoss, HTS/Amptek, Garnisch, Eltherm, GF Urecon, Flexelec, Fine Korea, Wuhu Jiahong New Material, Anhui Huanrui |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |