What is Global Inclined Impact Testing Machine Market?

The Global Inclined Impact Testing Machine Market refers to the industry focused on the production and distribution of machines designed to test the impact resistance of materials and products. These machines are crucial in assessing how materials behave under sudden force or impact, which is essential for ensuring safety and durability in various applications. The market encompasses a range of machines that vary in complexity and automation, catering to different industry needs. These machines are used extensively in industries such as packaging, transportation, and scientific research, where understanding the impact resistance of materials is vital. The market is driven by the increasing demand for high-quality, durable products that can withstand physical stress and impact. As industries continue to innovate and develop new materials, the need for reliable testing equipment like inclined impact testing machines grows, making this market an essential component of quality assurance processes across multiple sectors.

Manual, Semi-Automatic, Fully Automatic in the Global Inclined Impact Testing Machine Market:

Inclined impact testing machines are categorized based on their level of automation: manual, semi-automatic, and fully automatic. Manual inclined impact testing machines require human intervention for operation. These machines are typically more affordable and are suitable for smaller operations or educational purposes where budget constraints are a concern. They offer flexibility and control, allowing operators to manually adjust settings and parameters to suit specific testing requirements. However, manual machines can be labor-intensive and may not be ideal for high-volume testing due to the time and effort required for each test. Semi-automatic inclined impact testing machines offer a balance between manual and fully automatic systems. They incorporate some level of automation, reducing the need for constant human intervention while still allowing for manual adjustments. These machines are ideal for medium-sized operations where efficiency and precision are important but full automation is not necessary. Semi-automatic machines can handle a moderate volume of tests with greater consistency and accuracy than manual machines, making them a popular choice for many industries. Fully automatic inclined impact testing machines represent the pinnacle of technology in this market. These machines are designed for high-volume testing environments where speed, accuracy, and consistency are paramount. Fully automatic machines require minimal human intervention, as they are equipped with advanced software and sensors that control the entire testing process. This level of automation ensures that tests are conducted with precision and repeatability, reducing the risk of human error. Fully automatic machines are ideal for large-scale industrial applications where the demand for testing is high, and the cost of errors can be significant. The choice between manual, semi-automatic, and fully automatic inclined impact testing machines depends on several factors, including budget, testing volume, and the level of precision required. Each type of machine offers unique advantages and is suited to different applications, making it important for businesses to carefully consider their specific needs when selecting a testing machine. As technology continues to advance, the capabilities of these machines are likely to improve, offering even greater efficiency and accuracy in impact testing.

Packaging Industry, Scientific Research Industry, Transportation Industry, Others in the Global Inclined Impact Testing Machine Market:

The Global Inclined Impact Testing Machine Market finds its application across various industries, each with specific requirements and benefits from using these machines. In the packaging industry, inclined impact testing machines are crucial for ensuring that packaging materials can withstand the rigors of transportation and handling. These machines help manufacturers test the durability and impact resistance of packaging materials, such as cardboard, plastic, and metal, ensuring that products are protected during transit. By simulating real-world impact scenarios, these machines enable packaging companies to design more robust and reliable packaging solutions, reducing the risk of damage and loss during shipping. In the scientific research industry, inclined impact testing machines are used to study the properties of materials under impact conditions. Researchers use these machines to test new materials and composites, gaining insights into their behavior and performance. This information is vital for developing innovative materials with enhanced impact resistance, which can be used in various applications, from aerospace to consumer electronics. The ability to accurately measure and analyze the impact resistance of materials is essential for advancing scientific knowledge and driving innovation in material science. The transportation industry also relies heavily on inclined impact testing machines to ensure the safety and reliability of vehicles and components. These machines are used to test the impact resistance of various parts, such as bumpers, doors, and chassis, ensuring that they can withstand collisions and other impact events. By conducting rigorous testing, manufacturers can improve the safety features of vehicles, reducing the risk of injury and damage in the event of an accident. Inclined impact testing machines play a critical role in the development of safer and more reliable transportation solutions. Beyond these industries, inclined impact testing machines are used in various other sectors, including construction, electronics, and consumer goods. In construction, these machines help test the impact resistance of building materials, ensuring that structures can withstand environmental forces and physical stress. In electronics, they are used to test the durability of devices and components, ensuring that they can withstand drops and impacts. In the consumer goods industry, inclined impact testing machines help manufacturers ensure that products are durable and safe for everyday use. Overall, the Global Inclined Impact Testing Machine Market serves a wide range of industries, providing essential tools for testing and ensuring the quality and safety of materials and products.

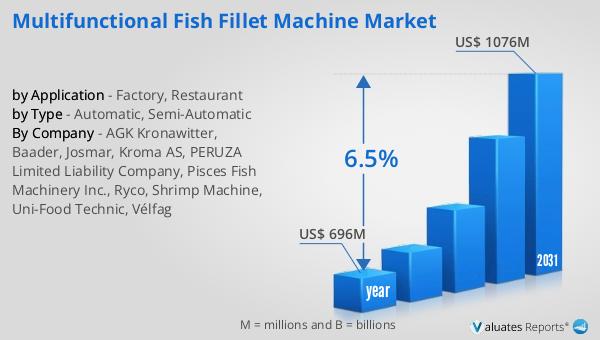

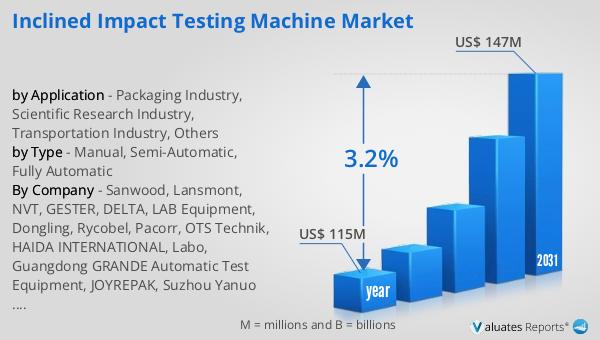

Global Inclined Impact Testing Machine Market Outlook:

The global market for Inclined Impact Testing Machines was valued at approximately $115 million in 2024. It is anticipated to grow steadily, reaching an estimated value of $147 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.2% over the forecast period. The market's expansion is driven by the increasing demand for reliable and efficient testing equipment across various industries. As companies continue to prioritize quality assurance and safety, the need for advanced testing machines that can accurately assess the impact resistance of materials and products becomes more critical. The market's growth is also supported by technological advancements in testing equipment, which enhance the precision and efficiency of impact testing processes. As industries such as packaging, transportation, and scientific research continue to evolve and innovate, the demand for inclined impact testing machines is expected to rise. This market outlook highlights the importance of inclined impact testing machines in ensuring the quality and safety of products across multiple sectors, making them an essential component of modern manufacturing and quality assurance processes.

| Report Metric | Details |

| Report Name | Inclined Impact Testing Machine Market |

| Accounted market size in year | US$ 115 million |

| Forecasted market size in 2031 | US$ 147 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sanwood, Lansmont, NVT, GESTER, DELTA, LAB Equipment, Dongling, Rycobel, Pacorr, OTS Technik, HAIDA INTERNATIONAL, Labo, Guangdong GRANDE Automatic Test Equipment, JOYREPAK, Suzhou Yanuo World Instrument, Labtone, WEEKEND, HENGYU, GBTC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |