What is Global Hydrogenated Bisphenol A Sales Market?

The Global Hydrogenated Bisphenol A Sales Market is a niche yet significant segment within the broader chemical industry. Hydrogenated Bisphenol A (HBPA) is a derivative of Bisphenol A, which is widely used in the production of epoxy resins and polycarbonate plastics. The hydrogenation process enhances the thermal stability and chemical resistance of Bisphenol A, making HBPA a valuable component in various industrial applications. The market for HBPA is driven by its demand in sectors such as electronics, automotive, and construction, where it is used to produce high-performance materials. The increasing need for durable and efficient materials in these industries has led to a steady growth in the HBPA market. Additionally, the push towards more sustainable and environmentally friendly products has further fueled the demand for HBPA, as it offers improved performance characteristics while reducing environmental impact. The market is characterized by a few key players who dominate the production and distribution of HBPA, ensuring a consistent supply to meet the growing demand. Overall, the Global Hydrogenated Bisphenol A Sales Market is poised for continued growth as industries seek advanced materials to enhance their products and processes.

in the Global Hydrogenated Bisphenol A Sales Market:

In the Global Hydrogenated Bisphenol A Sales Market, various types of HBPA are utilized by different customers based on their specific needs and applications. One of the primary types is the Epoxy Resin-used Hydrogenated Bisphenol A, which is the largest segment in the market, accounting for about 75% of the total share. This type is highly sought after due to its superior properties, such as excellent adhesion, chemical resistance, and mechanical strength, making it ideal for use in coatings, adhesives, and composite materials. Customers in the electronics industry, for instance, rely on this type of HBPA for manufacturing printed circuit boards and other electronic components that require high thermal stability and reliability. Another type of HBPA is used in the production of polycarbonate plastics, which are known for their transparency, impact resistance, and dimensional stability. These plastics are widely used in the automotive and construction industries for applications such as headlamp lenses, glazing, and roofing materials. The versatility of HBPA in enhancing the performance of polycarbonate plastics makes it a preferred choice for manufacturers looking to produce lightweight and durable products. Additionally, there is a growing demand for HBPA in the production of specialty polymers and elastomers, which are used in various high-performance applications. These materials benefit from the enhanced properties of HBPA, such as improved flexibility, toughness, and resistance to environmental factors. Customers in the automotive sector, for example, use these specialty polymers in the production of seals, gaskets, and other components that require long-lasting performance under harsh conditions. Furthermore, the construction industry utilizes HBPA-based materials for applications such as flooring, insulation, and structural components, where durability and resistance to wear and tear are crucial. The diverse range of HBPA types available in the market allows customers to select the most suitable option for their specific requirements, ensuring optimal performance and efficiency in their products and processes. As industries continue to evolve and demand more advanced materials, the Global Hydrogenated Bisphenol A Sales Market is expected to expand, offering new opportunities for innovation and growth.

in the Global Hydrogenated Bisphenol A Sales Market:

The Global Hydrogenated Bisphenol A Sales Market finds applications across a wide range of industries, each leveraging the unique properties of HBPA to enhance their products and processes. One of the primary applications is in the electronics industry, where HBPA is used in the production of epoxy resins for electronic packaging. This application accounts for about 40% of the market share, highlighting its significance in the industry. The use of HBPA in electronic packaging ensures high thermal stability, excellent electrical insulation, and resistance to moisture and chemicals, making it ideal for protecting sensitive electronic components. In the automotive industry, HBPA is used in the production of polycarbonate plastics and specialty polymers, which are essential for manufacturing lightweight and durable components. These materials are used in applications such as headlamp lenses, interior trims, and under-the-hood components, where they provide excellent impact resistance, dimensional stability, and resistance to environmental factors. The construction industry also benefits from the use of HBPA-based materials, particularly in applications that require high-performance coatings, adhesives, and composite materials. These materials offer superior adhesion, chemical resistance, and mechanical strength, making them suitable for use in flooring, insulation, and structural components. Additionally, the versatility of HBPA allows for its use in the production of specialty elastomers, which are used in various high-performance applications across different industries. These elastomers benefit from the enhanced properties of HBPA, such as improved flexibility, toughness, and resistance to environmental factors, making them ideal for use in seals, gaskets, and other components that require long-lasting performance under harsh conditions. As industries continue to seek advanced materials to enhance their products and processes, the applications of HBPA are expected to expand, offering new opportunities for innovation and growth in the Global Hydrogenated Bisphenol A Sales Market.

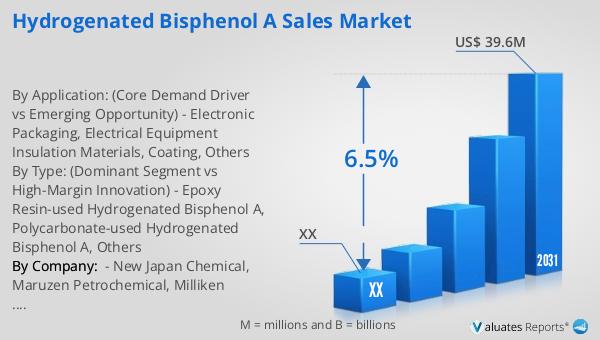

Global Hydrogenated Bisphenol A Sales Market Outlook:

The outlook for the Global Hydrogenated Bisphenol A market indicates a promising growth trajectory. In 2024, the market size was valued at approximately US$ 25.7 million, and it is projected to reach an adjusted size of US$ 39.6 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.5% during the forecast period from 2025 to 2031. This growth is driven by the increasing demand for HBPA in various industrial applications, particularly in the electronics and automotive sectors. The market is dominated by two major players who collectively hold over 60% of the market share, underscoring the competitive nature of the industry. In terms of product type, Epoxy Resin-used Hydrogenated Bisphenol A is the largest segment, accounting for about 75% of the market share. This dominance is attributed to the superior properties of epoxy resins, such as excellent adhesion, chemical resistance, and mechanical strength, which make them ideal for use in coatings, adhesives, and composite materials. In terms of application, electronic packaging holds a significant share of about 40%, highlighting the importance of HBPA in ensuring high thermal stability and reliability in electronic components. As industries continue to evolve and demand more advanced materials, the Global Hydrogenated Bisphenol A market is poised for continued growth, offering new opportunities for innovation and development.

| Report Metric | Details |

| Report Name | Hydrogenated Bisphenol A Sales Market |

| Forecasted market size in 2031 | US$ 39.6 million |

| CAGR | 6.5% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | New Japan Chemical, Maruzen Petrochemical, Milliken Chemical, Puyang Huicheng Electronic Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |