What is Global High Temperature Insulating Bulk Fibres Market?

The Global High Temperature Insulating Bulk Fibres Market is a specialized segment within the broader insulation industry, focusing on materials that can withstand extremely high temperatures while providing effective thermal insulation. These fibres are essential in industries where high heat resistance is crucial, such as aerospace, automotive, and industrial manufacturing. The market is driven by the increasing demand for energy-efficient solutions and the need to reduce energy consumption in high-temperature applications. High temperature insulating bulk fibres are typically made from materials like alumina, silica, and zirconia, which can endure temperatures exceeding 1000°C. These fibres are used in various forms, including blankets, boards, and papers, to suit different industrial needs. The market is characterized by continuous innovation, with manufacturers striving to develop fibres that offer better insulation properties, longer lifespans, and are environmentally friendly. As industries continue to seek ways to improve energy efficiency and reduce carbon footprints, the demand for high temperature insulating bulk fibres is expected to grow, making it a vital component of modern industrial processes.

Short Fiber, Long Fiber in the Global High Temperature Insulating Bulk Fibres Market:

In the Global High Temperature Insulating Bulk Fibres Market, fibres are generally categorized into short fibres and long fibres, each serving distinct purposes and applications. Short fibres are typically less than 10 millimeters in length and are often used in applications where flexibility and ease of handling are crucial. These fibres are commonly used in the production of lightweight insulating materials, such as felts and mats, which can be easily shaped and installed in complex geometries. Short fibres are particularly valued for their ability to provide uniform insulation coverage, making them ideal for applications in the aerospace and automotive industries, where weight reduction and thermal efficiency are paramount. On the other hand, long fibres, which can exceed 10 millimeters in length, are used in applications that require higher mechanical strength and durability. These fibres are often woven into fabrics or used to reinforce composite materials, providing enhanced structural integrity and thermal resistance. Long fibres are commonly used in the construction of high-temperature industrial equipment, such as kilns and furnaces, where they help maintain structural stability under extreme heat conditions. The choice between short and long fibres depends on the specific requirements of the application, including factors such as temperature range, mechanical stress, and environmental conditions. Manufacturers in the Global High Temperature Insulating Bulk Fibres Market are continually innovating to improve the performance characteristics of both short and long fibres, focusing on enhancing thermal insulation properties, mechanical strength, and environmental sustainability. This ongoing innovation is driven by the increasing demand for high-performance insulating materials in various industries, including aerospace, automotive, and industrial manufacturing. As industries continue to evolve and seek more efficient and sustainable solutions, the role of short and long fibres in the Global High Temperature Insulating Bulk Fibres Market is expected to become increasingly significant, offering new opportunities for growth and development.

Metallurgical Industry, Petrochemical Industry, Electronics Industry, Others in the Global High Temperature Insulating Bulk Fibres Market:

The Global High Temperature Insulating Bulk Fibres Market finds extensive usage across various industries, including the metallurgical, petrochemical, electronics, and others, due to its exceptional thermal insulation properties. In the metallurgical industry, these fibres are crucial for lining furnaces, kilns, and other high-temperature processing equipment. They help in maintaining the necessary temperature levels while minimizing heat loss, thereby improving energy efficiency and reducing operational costs. The ability of these fibres to withstand extreme temperatures without degrading makes them ideal for use in environments where metals are melted, cast, or heat-treated. In the petrochemical industry, high temperature insulating bulk fibres are used in the insulation of reactors, reformers, and other processing units that operate at elevated temperatures. These fibres help in maintaining the thermal stability of the equipment, ensuring efficient chemical reactions and preventing heat-related damage. The use of these fibres in the petrochemical industry also contributes to energy conservation and emission reduction, aligning with the industry's goals of sustainability and environmental responsibility. In the electronics industry, high temperature insulating bulk fibres are used in the manufacturing of components that require thermal management, such as semiconductors and circuit boards. These fibres help in dissipating heat generated during the operation of electronic devices, preventing overheating and ensuring optimal performance. The use of high temperature insulating bulk fibres in the electronics industry is driven by the increasing demand for miniaturized and high-performance electronic devices, which require efficient thermal management solutions. Beyond these industries, high temperature insulating bulk fibres are also used in various other applications, including the construction of high-temperature industrial equipment, automotive components, and aerospace systems. The versatility and adaptability of these fibres make them an essential component in modern industrial processes, contributing to improved energy efficiency, reduced environmental impact, and enhanced performance across a wide range of applications.

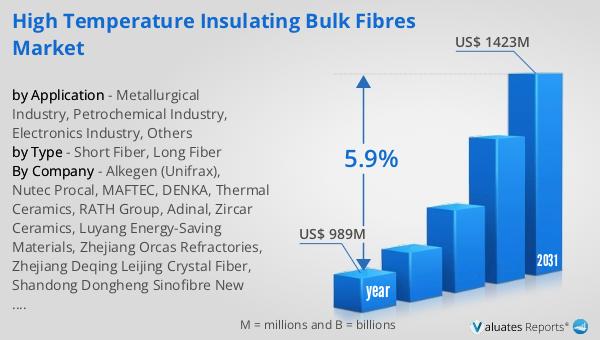

Global High Temperature Insulating Bulk Fibres Market Outlook:

The global market for High Temperature Insulating Bulk Fibres was valued at approximately $989 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is expected to reach an estimated size of $1,423 million, reflecting a compound annual growth rate (CAGR) of 5.9% during the forecast period. This growth is driven by the increasing demand for energy-efficient solutions and the need to reduce energy consumption in high-temperature applications across various industries. The market's expansion is also supported by continuous innovation in fibre materials and manufacturing processes, which aim to enhance the thermal insulation properties, mechanical strength, and environmental sustainability of these fibres. As industries continue to seek ways to improve energy efficiency and reduce carbon footprints, the demand for high temperature insulating bulk fibres is expected to grow, making it a vital component of modern industrial processes. The market's growth trajectory highlights the importance of these fibres in addressing the challenges of energy conservation and environmental sustainability, offering new opportunities for manufacturers and end-users alike. As the market continues to evolve, stakeholders are likely to focus on developing advanced materials and technologies that meet the changing needs of industries and contribute to a more sustainable future.

| Report Metric | Details |

| Report Name | High Temperature Insulating Bulk Fibres Market |

| Accounted market size in year | US$ 989 million |

| Forecasted market size in 2031 | US$ 1423 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Alkegen (Unifrax), Nutec Procal, MAFTEC, DENKA, Thermal Ceramics, RATH Group, Adinal, Zircar Ceramics, Luyang Energy-Saving Materials, Zhejiang Orcas Refractories, Zhejiang Deqing Leijing Crystal Fiber, Shandong Dongheng Sinofibre New Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |