What is Global Helical Rotor Pumps Market?

The Global Helical Rotor Pumps Market is a significant segment within the broader industrial pumps industry, characterized by its unique design and operational efficiency. Helical rotor pumps, also known as progressive cavity pumps, are positive displacement pumps that use a helical rotor to move fluids through a series of cavities. This design allows for the smooth and continuous flow of liquids, making them ideal for handling viscous, shear-sensitive, or abrasive fluids. These pumps are widely used across various industries due to their ability to handle a wide range of fluid types and their robust performance in challenging conditions. The market for helical rotor pumps is driven by the increasing demand for efficient and reliable pumping solutions in industries such as oil and gas, water and wastewater treatment, and food and beverage processing. Additionally, advancements in pump technology and the growing focus on energy efficiency are further propelling the market's growth. As industries continue to seek solutions that offer both performance and sustainability, the demand for helical rotor pumps is expected to remain strong. The market's expansion is also supported by the ongoing industrialization and infrastructure development in emerging economies, which are key factors contributing to the rising adoption of these pumps globally.

Twin-Screw Pumps, Three Screw Pumps, Other Multi-Screw Pumps in the Global Helical Rotor Pumps Market:

Twin-screw pumps, three-screw pumps, and other multi-screw pumps are integral components of the Global Helical Rotor Pumps Market, each offering distinct advantages and applications. Twin-screw pumps are renowned for their ability to handle a wide range of viscosities and are particularly valued in industries where the gentle handling of fluids is crucial. These pumps operate by using two intermeshing screws that rotate in opposite directions, creating a sealed cavity that moves the fluid from the pump's inlet to its outlet. This design ensures a smooth, pulsation-free flow, making twin-screw pumps ideal for applications in the food and beverage industry, where maintaining the integrity of the product is essential. Additionally, their ability to handle multiphase fluids makes them suitable for the oil and gas sector, where they are used for transporting crude oil and other hydrocarbons. Three-screw pumps, on the other hand, are primarily used in applications requiring high pressure and low flow rates. These pumps consist of a central drive screw that intermeshes with two idler screws, creating a sealed cavity that moves the fluid. This design allows for efficient handling of lubricating fluids, making three-screw pumps a popular choice in the marine industry for fuel and lubrication oil transfer. Their compact design and ability to operate at high pressures also make them suitable for use in hydraulic systems and power generation applications. Other multi-screw pumps, which include designs with more than three screws, offer enhanced performance characteristics, such as increased flow rates and improved efficiency. These pumps are often used in specialized applications where standard pump designs may not suffice. For instance, in the chemical and petrochemical industries, multi-screw pumps are used to handle aggressive and corrosive fluids, thanks to their robust construction and ability to maintain a consistent flow. The versatility of multi-screw pumps makes them an attractive option for industries seeking reliable and efficient pumping solutions. Overall, the diversity of screw pump designs within the Global Helical Rotor Pumps Market highlights the adaptability and innovation present in this sector. As industries continue to evolve and demand more specialized solutions, the role of twin-screw, three-screw, and other multi-screw pumps will remain pivotal in meeting these needs.

Chemical & Petrochemical Industries, Mechanical Engineering, Power Generation, Marine, Other Applications in the Global Helical Rotor Pumps Market:

The Global Helical Rotor Pumps Market finds extensive usage across various industries, each benefiting from the unique capabilities of these pumps. In the chemical and petrochemical industries, helical rotor pumps are indispensable due to their ability to handle a wide range of aggressive and corrosive fluids. These industries require pumps that can maintain a consistent flow while minimizing the risk of leaks and contamination. Helical rotor pumps, with their robust construction and efficient sealing mechanisms, are well-suited for these demanding applications. They are used for transferring chemicals, solvents, and other hazardous materials, ensuring safe and reliable operations. In mechanical engineering, helical rotor pumps play a crucial role in processes that require precise fluid handling. Their ability to deliver a steady flow of fluids makes them ideal for applications such as lubrication systems, where maintaining the integrity of the machinery is paramount. These pumps are also used in hydraulic systems, providing the necessary pressure and flow to power various mechanical operations. The power generation industry relies on helical rotor pumps for their efficiency and reliability in handling cooling and lubrication fluids. These pumps are used in power plants to circulate water and other fluids, ensuring optimal performance and preventing overheating. Their ability to operate under high temperatures and pressures makes them a preferred choice in this sector. In the marine industry, helical rotor pumps are used for fuel transfer, bilge pumping, and ballast water management. Their robust design and ability to handle a variety of fluids make them suitable for the harsh conditions encountered at sea. Additionally, their compact size and efficiency are advantageous in the confined spaces of marine vessels. Beyond these industries, helical rotor pumps are also used in a range of other applications, including water and wastewater treatment, food and beverage processing, and pharmaceuticals. In water treatment, these pumps are used for dosing chemicals and transferring sludge, while in the food industry, they handle viscous products such as syrups and sauces. The pharmaceutical industry benefits from the gentle handling of sensitive fluids, ensuring product integrity and quality. Overall, the versatility and reliability of helical rotor pumps make them an essential component in various industrial processes, contributing to their widespread adoption across multiple sectors.

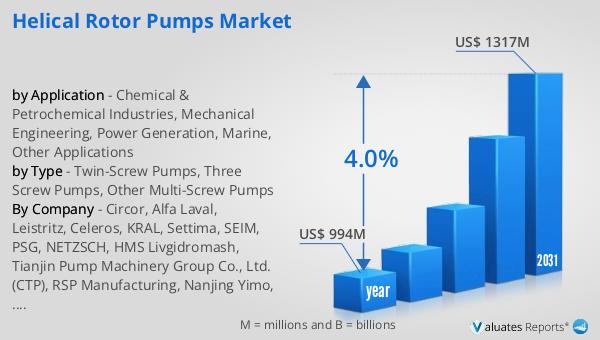

Global Helical Rotor Pumps Market Outlook:

In 2024, the global market for Helical Rotor Pumps was valued at approximately $994 million. By 2031, it is anticipated to grow to a revised size of around $1,317 million, reflecting a compound annual growth rate (CAGR) of 4.0% over the forecast period. This growth trajectory underscores the increasing demand for helical rotor pumps across various industries, driven by their efficiency and versatility in handling diverse fluid types. The Asia-Pacific region stands out as the largest consumer of these pumps, accounting for about 28% of the global market. This significant share is attributed to the rapid industrialization and infrastructure development in countries within this region, which are fueling the demand for reliable and efficient pumping solutions. The robust growth in sectors such as oil and gas, water treatment, and food processing in Asia-Pacific further contributes to the region's dominance in the market. As industries continue to seek advanced technologies that offer both performance and sustainability, the demand for helical rotor pumps is expected to remain strong. The market's expansion is also supported by ongoing technological advancements and the increasing focus on energy efficiency, which are key factors driving the adoption of these pumps globally. Overall, the Global Helical Rotor Pumps Market is poised for steady growth, with the Asia-Pacific region leading the way in terms of consumption and market share.

| Report Metric | Details |

| Report Name | Helical Rotor Pumps Market |

| Accounted market size in year | US$ 994 million |

| Forecasted market size in 2031 | US$ 1317 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Circor, Alfa Laval, Leistritz, Celeros, KRAL, Settima, SEIM, PSG, NETZSCH, HMS Livgidromash, Tianjin Pump Machinery Group Co., Ltd. (CTP), RSP Manufacturing, Nanjing Yimo, Xinglong Pump, Delta Corporation, Aiken Machinery, Tianjin Huaman Pumps, ITT Bornemann, Flowserve, Klaus Union, Pumpenfabrik Wangen, Fristam, Kosaka Laboratory, Mingjie Pump, THE VERDER |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |