What is Global Feeler Gauge Sales Market?

The Global Feeler Gauge Sales Market refers to the worldwide industry involved in the production, distribution, and sale of feeler gauges. These are precision tools used to measure gap widths or clearances between two parts. Typically made from high-quality materials like steel, feeler gauges are essential in various industries, including automotive, aerospace, and manufacturing, where precise measurements are crucial. The market encompasses a range of products, from simple, single-blade gauges to complex sets with multiple blades of varying thicknesses. The demand for feeler gauges is driven by the need for accuracy and efficiency in mechanical and engineering tasks. As industries continue to advance technologically, the requirement for precise measurement tools like feeler gauges is expected to grow, contributing to the market's expansion. The market is characterized by a mix of established manufacturers and new entrants, each striving to offer innovative products that meet the evolving needs of their customers. With a focus on quality, durability, and precision, the Global Feeler Gauge Sales Market plays a vital role in supporting industries that rely on accurate measurements for their operations.

in the Global Feeler Gauge Sales Market:

Feeler gauges come in various types, each designed to meet the specific needs of different customers across the Global Feeler Gauge Sales Market. The most common type is the steel feeler gauge, which dominates the market due to its durability and precision. Steel feeler gauges are preferred in industries where high accuracy is required, such as automotive and aerospace, because they can withstand wear and tear while providing consistent measurements. Another type is the brass feeler gauge, which is used in environments where non-magnetic properties are essential. Brass gauges are ideal for applications involving electronic components or where magnetic interference could be an issue. Plastic feeler gauges are also available and are typically used in situations where electrical conductivity needs to be avoided, or where a softer material is required to prevent scratching delicate surfaces. These are often used in the electronics industry or in applications involving sensitive materials. Additionally, there are tapered feeler gauges, which are designed for measuring gaps that are not uniform in width. These are particularly useful in automotive and machinery maintenance, where components may not be perfectly aligned. Another variation is the go/no-go feeler gauge, which is used for quick checks to determine if a gap falls within a specified range. This type is commonly used in quality control processes where speed and efficiency are critical. Customers in the Global Feeler Gauge Sales Market choose the type of feeler gauge based on their specific requirements, considering factors such as the material being measured, the environment in which the gauge will be used, and the level of precision needed. For instance, in the automotive industry, where engine components must fit together with high precision, steel feeler gauges are often the tool of choice. In contrast, in the electronics industry, where non-conductive materials are necessary, plastic or brass gauges may be preferred. The choice of feeler gauge type is also influenced by the complexity of the task at hand. For simple measurements, a single-blade gauge may suffice, while more complex tasks may require a set of gauges with varying thicknesses. This allows for greater flexibility and accuracy in measurement. Furthermore, the ease of use and portability of feeler gauges make them a popular choice for fieldwork and on-site inspections, where quick and accurate measurements are essential. As the Global Feeler Gauge Sales Market continues to evolve, manufacturers are constantly innovating to meet the diverse needs of their customers. This includes developing gauges with enhanced features, such as digital readouts for improved accuracy and ease of use, or gauges made from advanced materials that offer greater durability and resistance to environmental factors. The variety of feeler gauges available ensures that customers can find the right tool for their specific application, whether it be in a high-tech manufacturing facility or a small automotive repair shop.

in the Global Feeler Gauge Sales Market:

The Global Feeler Gauge Sales Market serves a wide range of applications across various industries, each requiring precise measurement tools to ensure optimal performance and quality. In the automotive industry, feeler gauges are indispensable for tasks such as setting valve clearances, checking spark plug gaps, and ensuring proper alignment of engine components. These measurements are crucial for maintaining engine efficiency and performance, as even minor discrepancies can lead to significant issues over time. In the aerospace industry, feeler gauges are used to measure the clearance between critical components, ensuring that aircraft operate safely and efficiently. The precision required in aerospace applications is extremely high, making feeler gauges an essential tool for engineers and technicians. In the manufacturing sector, feeler gauges are used in quality control processes to verify that parts and components meet specified tolerances. This is particularly important in industries where precision is paramount, such as the production of medical devices or precision instruments. Feeler gauges are also used in the maintenance and repair of machinery, where they help technicians identify wear and tear or misalignment issues that could affect performance. In the electronics industry, feeler gauges are used to measure gaps in circuit boards and other components, ensuring that they fit together correctly and function as intended. The non-conductive properties of certain types of feeler gauges, such as those made from plastic or brass, make them ideal for use in environments where electrical conductivity must be avoided. Additionally, feeler gauges are used in the construction industry for tasks such as checking the alignment of structural components or verifying the thickness of materials. The versatility and precision of feeler gauges make them a valuable tool in any industry where accurate measurements are essential. As technology continues to advance, the applications for feeler gauges are likely to expand, with new industries and uses emerging. The Global Feeler Gauge Sales Market is poised to support these developments by providing high-quality, reliable measurement tools that meet the evolving needs of its customers.

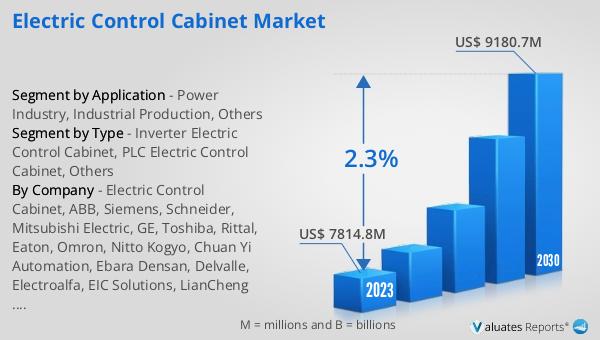

Global Feeler Gauge Sales Market Outlook:

In 2024, the global market for feeler gauges was valued at approximately $106 million. Projections indicate that by 2031, this market will grow to an estimated $116 million, reflecting a compound annual growth rate (CAGR) of 1.2% over the forecast period from 2025 to 2031. This steady growth underscores the ongoing demand for precision measurement tools across various industries. Notably, the top five manufacturers in the global market hold a significant share, collectively accounting for over 35% of the market. This concentration highlights the dominance of key players who continue to innovate and meet the diverse needs of their customers. Among the different types of feeler gauges available, steel feeler gauges represent the largest segment, commanding a market share of over 90%. This preference for steel gauges is largely due to their durability, precision, and versatility, making them the go-to choice for many industries, including automotive, aerospace, and manufacturing. The market's growth is driven by the increasing need for accurate and reliable measurement tools, as industries strive for greater efficiency and precision in their operations. As the market evolves, manufacturers are expected to continue developing innovative products that cater to the specific requirements of their customers, ensuring the sustained relevance and importance of feeler gauges in various applications.

| Report Metric | Details |

| Report Name | Feeler Gauge Sales Market |

| Forecasted market size in 2031 | US$ 116 million |

| CAGR | 1.2% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Stanley Black & Decker, TTI, SnapOn, ATG, Mitutoyo, Schaeffler, SKF, NTN, Great Star, Starrett, Great Wall, Endura, Jetech Tool, Eastern, Precision Brand, SP Air |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |