What is Global Enzyme for Pulp & Paper Sales Market?

The global enzyme market for pulp and paper sales is a specialized segment within the broader enzyme industry, focusing on the use of enzymes to enhance the production processes in the pulp and paper sector. Enzymes are biological catalysts that speed up chemical reactions, and in the context of pulp and paper, they are used to improve the efficiency and environmental sustainability of production. The market for these enzymes is driven by the increasing demand for paper products and the need for more sustainable and cost-effective production methods. Enzymes help in reducing the use of harsh chemicals, lowering energy consumption, and improving the quality of the final product. The market is characterized by a variety of enzyme types, each serving specific functions in the production process, such as bleaching, fiber modification, and pitch control. As the industry continues to evolve, the adoption of enzyme technology is expected to grow, driven by the dual pressures of environmental regulation and cost reduction. The global enzyme for pulp and paper sales market is thus a dynamic and evolving field, offering significant opportunities for innovation and growth.

in the Global Enzyme for Pulp & Paper Sales Market:

In the global enzyme market for pulp and paper sales, various types of enzymes are utilized by different customers to meet specific needs in the production process. One of the most commonly used enzymes is xylanase, which plays a crucial role in the bleaching process. Xylanase helps in breaking down hemicellulose, a component of plant cell walls, thereby facilitating the removal of lignin and enhancing the brightness of the paper. This enzyme is particularly valued for its ability to reduce the need for chlorine-based chemicals, making the bleaching process more environmentally friendly. Another important enzyme is cellulase, which is used for fiber modification. Cellulase breaks down cellulose fibers, improving the flexibility and strength of the paper. This enzyme is often used in the production of tissue paper and other products where softness and absorbency are important. Lipase is another enzyme used in the pulp and paper industry, primarily for pitch control. Pitch, a sticky substance found in wood, can cause problems during the paper-making process by sticking to machinery and reducing the quality of the final product. Lipase breaks down the pitch, preventing these issues and ensuring a smoother production process. Amylase is also used in the pulp and paper industry, particularly in the recycling process. Amylase breaks down starch, which is often used as a binder in paper products. By breaking down the starch, amylase facilitates the recycling of paper, making the process more efficient and cost-effective. Each of these enzymes serves a specific function in the pulp and paper production process, and their use is tailored to the specific needs of the customer. For example, a company focused on producing high-quality, bright white paper may prioritize the use of xylanase, while a company focused on producing soft tissue paper may prioritize the use of cellulase. The choice of enzyme is also influenced by factors such as cost, availability, and environmental regulations. In recent years, there has been a growing interest in the use of enzyme cocktails, which combine multiple enzymes to achieve a synergistic effect. These cocktails can be tailored to the specific needs of the customer, offering a more customized solution to the challenges of pulp and paper production. The use of enzyme cocktails is particularly appealing to companies looking to optimize their production processes and reduce their environmental impact. Overall, the global enzyme market for pulp and paper sales is characterized by a diverse range of enzyme types, each offering unique benefits to customers. The choice of enzyme is influenced by a variety of factors, including the specific needs of the customer, cost considerations, and environmental regulations. As the industry continues to evolve, the use of enzymes is expected to grow, driven by the need for more sustainable and cost-effective production methods.

in the Global Enzyme for Pulp & Paper Sales Market:

The global enzyme market for pulp and paper sales finds applications across various stages of the production process, each benefiting from the unique properties of enzymes. One of the primary applications is in the bleaching process, where enzymes like xylanase are used to enhance the brightness of the paper. By breaking down hemicellulose, xylanase facilitates the removal of lignin, a component that contributes to the color of the paper. This enzymatic process not only improves the brightness but also reduces the need for chlorine-based chemicals, making the process more environmentally friendly. Another significant application is in fiber modification, where enzymes such as cellulase are used to alter the properties of cellulose fibers. This modification improves the flexibility and strength of the paper, making it suitable for various applications, including tissue paper and packaging materials. The use of cellulase in fiber modification also enhances the softness and absorbency of the paper, which is particularly important in the production of tissue paper. Enzymes also play a crucial role in pitch control, a common challenge in the pulp and paper industry. Pitch, a sticky substance found in wood, can cause problems during the paper-making process by sticking to machinery and reducing the quality of the final product. Enzymes like lipase break down the pitch, preventing these issues and ensuring a smoother production process. This application is particularly important for companies looking to maintain high-quality standards and minimize production disruptions. In addition to these applications, enzymes are also used in the recycling process. Enzymes like amylase break down starch, which is often used as a binder in paper products. By breaking down the starch, amylase facilitates the recycling of paper, making the process more efficient and cost-effective. This application is particularly important in the context of increasing environmental regulations and the growing demand for sustainable production methods. The use of enzymes in the recycling process not only improves the efficiency of recycling but also enhances the quality of the recycled paper. Overall, the global enzyme market for pulp and paper sales offers a wide range of applications, each benefiting from the unique properties of enzymes. From bleaching and fiber modification to pitch control and recycling, enzymes play a crucial role in enhancing the efficiency and sustainability of the pulp and paper production process. As the industry continues to evolve, the use of enzymes is expected to grow, driven by the need for more sustainable and cost-effective production methods.

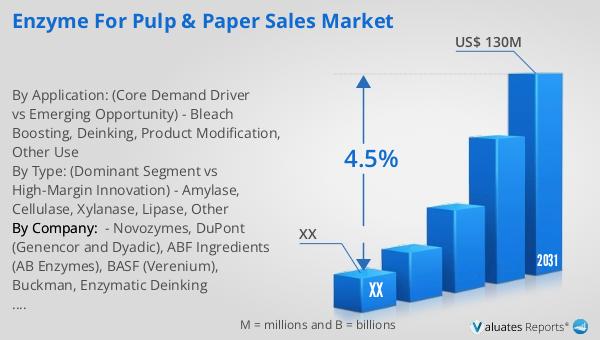

Global Enzyme for Pulp & Paper Sales Market Outlook:

In 2024, the global enzyme market for pulp and paper was valued at approximately $96 million. By 2031, it is projected to reach an adjusted size of $130 million, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period from 2025 to 2031. This growth is indicative of the increasing demand for enzymes in the pulp and paper industry, driven by the need for more sustainable and efficient production processes. The market is dominated by the top three manufacturers, who collectively hold a market share exceeding 60%. This concentration of market power highlights the competitive nature of the industry and the importance of innovation and differentiation for smaller players. Among the various enzyme types, xylanase stands out as the largest segment, accounting for over 35% of the market share. This dominance is due to xylanase's critical role in the bleaching process, where it helps reduce the use of chlorine-based chemicals and enhances the brightness of the paper. The strong market position of xylanase underscores the growing importance of environmentally friendly production methods in the pulp and paper industry. As the market continues to evolve, the focus on sustainability and efficiency is expected to drive further growth and innovation in the enzyme market for pulp and paper sales.

| Report Metric | Details |

| Report Name | Enzyme for Pulp & Paper Sales Market |

| Forecasted market size in 2031 | US$ 130 million |

| CAGR | 4.5% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Novozymes, DuPont (Genencor and Dyadic), ABF Ingredients (AB Enzymes), BASF (Verenium), Buckman, Enzymatic Deinking Technologies, Denykem, Metgen, Advanced Enzymes, Anil Bioplus, Leveking, Sukehan, Kdnbio, Yiduoli, Youtellbio |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |