What is Global Engineering Plastic Sales Market?

The Global Engineering Plastic Sales Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries worldwide. Engineering plastics are a group of plastic materials that exhibit superior mechanical and thermal properties compared to commodity plastics. These materials are used in applications that require high performance, durability, and resistance to harsh environmental conditions. The market for engineering plastics is driven by the increasing demand from industries such as automotive, electronics, construction, and consumer goods. As industries continue to innovate and develop new technologies, the need for materials that can withstand higher temperatures, pressures, and stresses becomes more critical. Engineering plastics offer solutions to these challenges, providing manufacturers with materials that can improve product performance and longevity. The global market is characterized by a diverse range of products, each tailored to meet specific industry needs, and is supported by ongoing research and development efforts aimed at enhancing the properties and applications of these materials. As a result, the Global Engineering Plastic Sales Market is poised for continued growth, driven by technological advancements and the expanding applications of engineering plastics across various sectors.

in the Global Engineering Plastic Sales Market:

The Global Engineering Plastic Sales Market encompasses a wide array of plastic types, each serving distinct purposes and catering to various customer needs. One of the most prominent types is Polycarbonate (PC), known for its high impact resistance and optical clarity, making it ideal for applications such as automotive headlamps, eyewear lenses, and electronic components. Another significant type is Polyamide (PA), commonly referred to as nylon, which is valued for its excellent mechanical properties and resistance to wear and chemicals. This makes it a preferred choice for automotive parts, industrial machinery, and consumer goods. Acrylonitrile Butadiene Styrene (ABS) is another versatile engineering plastic, appreciated for its toughness and ease of processing, often used in automotive interiors, consumer electronics, and toys. Polyoxymethylene (POM), also known as acetal, is renowned for its high stiffness, low friction, and excellent dimensional stability, making it suitable for precision parts in automotive and industrial applications. Polyethylene Terephthalate (PET) is widely used in the packaging industry due to its strength, thermal stability, and recyclability. It is commonly found in beverage bottles, food containers, and synthetic fibers. Polybutylene Terephthalate (PBT) is another engineering plastic that offers good electrical properties and resistance to chemicals, making it ideal for electrical and electronic components. Polyphenylene Oxide (PPO) is known for its high heat resistance and dimensional stability, often used in automotive and electrical applications. Polysulfone (PSU) is valued for its transparency and resistance to high temperatures, commonly used in medical devices and food processing equipment. Each of these engineering plastics is designed to meet specific performance criteria, allowing manufacturers to select the most appropriate material for their applications. The diversity of engineering plastics available in the market ensures that there is a suitable option for virtually any industrial requirement, from high-strength automotive components to lightweight consumer electronics. As industries continue to evolve and demand more advanced materials, the range of engineering plastics is expected to expand further, offering even more specialized solutions to meet the ever-changing needs of customers worldwide.

in the Global Engineering Plastic Sales Market:

The applications of engineering plastics in the Global Engineering Plastic Sales Market are vast and varied, reflecting the versatility and adaptability of these materials. In the automotive industry, engineering plastics are used extensively to reduce vehicle weight, improve fuel efficiency, and enhance safety features. Components such as bumpers, dashboards, and fuel systems benefit from the strength and durability of materials like polycarbonate and polyamide. In the electronics sector, engineering plastics are crucial for producing lightweight, durable, and heat-resistant components. They are used in the manufacturing of connectors, enclosures, and circuit boards, where materials like polybutylene terephthalate and polyphenylene oxide provide excellent electrical insulation and thermal stability. The construction industry also relies on engineering plastics for applications such as piping, insulation, and glazing. Materials like polyvinyl chloride and polyethylene terephthalate offer the necessary strength and weather resistance for these demanding environments. In the medical field, engineering plastics are used to produce devices and equipment that require high levels of hygiene and biocompatibility. Polysulfone and polycarbonate are commonly used in medical instruments, surgical tools, and diagnostic equipment due to their ability to withstand sterilization processes and maintain clarity. The consumer goods sector benefits from engineering plastics in the production of durable and aesthetically pleasing products. From household appliances to sports equipment, materials like acrylonitrile butadiene styrene and polyoxymethylene provide the necessary balance of strength, flexibility, and ease of manufacturing. The packaging industry also utilizes engineering plastics to create lightweight, strong, and recyclable packaging solutions. Polyethylene terephthalate is a popular choice for beverage bottles and food containers due to its excellent barrier properties and recyclability. As industries continue to innovate and seek more sustainable and efficient solutions, the applications of engineering plastics are expected to grow, offering new opportunities for manufacturers and consumers alike.

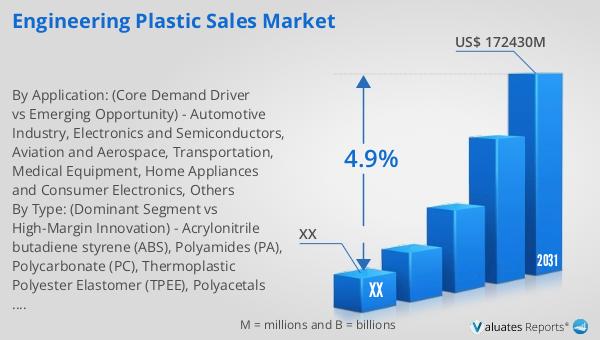

Global Engineering Plastic Sales Market Outlook:

In 2024, the global engineering plastic market was valued at approximately $124.35 billion. This figure is projected to increase significantly, reaching an estimated $172.43 billion by 2031. This growth represents a compound annual growth rate (CAGR) of 4.9% over the forecast period from 2025 to 2031. The expansion of the market can be attributed to several factors, including the increasing demand for high-performance materials in various industries such as automotive, electronics, and construction. As these industries continue to evolve and innovate, the need for materials that offer superior mechanical and thermal properties becomes more critical. Engineering plastics provide solutions to these challenges, offering manufacturers materials that can enhance product performance and longevity. The market's growth is also supported by ongoing research and development efforts aimed at improving the properties and applications of engineering plastics. As a result, the global engineering plastic market is expected to continue its upward trajectory, driven by technological advancements and the expanding applications of these materials across various sectors. This growth presents significant opportunities for manufacturers, suppliers, and consumers, as the demand for high-performance materials continues to rise.

| Report Metric | Details |

| Report Name | Engineering Plastic Sales Market |

| Forecasted market size in 2031 | US$ 172430 million |

| CAGR | 4.9% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Ineos, Covestro, SABIC, Mitsubishi Chemical, Lotte Chemical, Teijin Limited, DSM, Victrex, Solvay, Evonik, Arkema, UBE Industries, BASF SE, AdvanSix, Lanxess, Clariant Corporation, Toray, JSR, Röhm, Sumitomo Chemical, LX MMA, Celanese, Asahi Kasei, LyondellBasell, Kolon Plastics, DuPont, Kuraray, Idemitsu Kosan, Trinseo, CHIMEI, LG Chem, Samyang Kasei, SIBUR (Kazanorgsintez), Sinopec, Wanhua Chemical, Formosa, CNPC, Dagu Chemical, KKPC, EMS-Grivory, Unitika, DOMO Chemicals, Grupa Azoty, LIBOLON, Polymeric Resources Corporation (PRC), Shakespeare, Huajin Chemical, Gaoqiao, Grand Pacific Petrochemical, Kumho Sunny, MEP, Polyplastics, DIC, Kureha, Plaskolite, PTTAC, Dow, Avient |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |