What is Global Continuous Fiber Reinforced Thermoplastic Composites Sales Market?

The Global Continuous Fiber Reinforced Thermoplastic Composites Sales Market is a specialized segment within the broader composites industry, focusing on materials that combine continuous fibers with thermoplastic matrices. These composites are known for their exceptional strength-to-weight ratio, durability, and versatility, making them highly sought after in various industries. Continuous fibers, such as glass, carbon, or aramid, are embedded in a thermoplastic matrix, resulting in a material that can be easily molded and reshaped while maintaining structural integrity. This market is driven by the increasing demand for lightweight and high-performance materials, particularly in sectors like aerospace, automotive, and construction. The ability of these composites to withstand harsh environmental conditions and their recyclability further enhance their appeal. As industries continue to prioritize sustainability and efficiency, the demand for continuous fiber reinforced thermoplastic composites is expected to grow, offering innovative solutions for modern engineering challenges. The market's growth is also supported by advancements in manufacturing technologies, which enable more cost-effective and scalable production processes. Overall, the Global Continuous Fiber Reinforced Thermoplastic Composites Sales Market represents a dynamic and evolving field with significant potential for future development.

in the Global Continuous Fiber Reinforced Thermoplastic Composites Sales Market:

The Global Continuous Fiber Reinforced Thermoplastic Composites Sales Market encompasses a variety of types, each catering to specific customer needs and applications. One of the most prevalent types is the Glass Fiber Reinforced Thermoplastic (GFRT) composites, which dominate the market due to their cost-effectiveness and excellent mechanical properties. Glass fibers are widely used because they offer a good balance of strength, weight, and affordability, making them suitable for a broad range of applications, from automotive components to consumer electronics. Another significant type is Carbon Fiber Reinforced Thermoplastic (CFRT) composites, known for their superior strength and stiffness. Although more expensive than glass fibers, carbon fibers are preferred in high-performance applications where weight reduction and structural integrity are critical, such as in aerospace and high-end automotive sectors. Aramid Fiber Reinforced Thermoplastic (AFRT) composites are also part of this market, offering exceptional impact resistance and thermal stability. These are often used in military and protective gear applications where durability and safety are paramount. Additionally, hybrid composites, which combine different types of fibers, are gaining traction. These hybrids allow manufacturers to tailor the properties of the composite to meet specific requirements, offering a balance between performance and cost. The choice of fiber type is influenced by factors such as the intended application, environmental conditions, and budget constraints. For instance, in the automotive industry, where reducing vehicle weight is crucial for improving fuel efficiency, manufacturers might opt for carbon fiber composites despite their higher cost. In contrast, for consumer goods where cost is a significant consideration, glass fiber composites might be more appropriate. The versatility of continuous fiber reinforced thermoplastic composites is further enhanced by the variety of thermoplastic matrices available, such as polypropylene, polyamide, and polyetheretherketone (PEEK). Each matrix offers distinct properties, such as chemical resistance, thermal stability, and ease of processing, allowing for further customization of the composite material. The market is also witnessing innovations in fiber and matrix technologies, leading to the development of new composite types with enhanced properties. For example, advancements in nanotechnology are enabling the incorporation of nanofibers into thermoplastic matrices, resulting in composites with improved mechanical and thermal properties. These innovations are expanding the potential applications of continuous fiber reinforced thermoplastic composites, making them an attractive option for industries seeking to enhance product performance and sustainability. As the market continues to evolve, the diversity of composite types available will likely increase, providing customers with a wider range of options to meet their specific needs.

in the Global Continuous Fiber Reinforced Thermoplastic Composites Sales Market:

The applications of Global Continuous Fiber Reinforced Thermoplastic Composites Sales Market are diverse and span across multiple industries, each leveraging the unique properties of these materials to enhance product performance and efficiency. In the aerospace industry, these composites are used extensively for manufacturing aircraft components such as fuselage panels, wing structures, and interior parts. The lightweight nature of these materials contributes to fuel efficiency and reduces emissions, aligning with the industry's sustainability goals. In the automotive sector, continuous fiber reinforced thermoplastic composites are employed in the production of various parts, including bumpers, dashboards, and structural components. The use of these materials helps in reducing vehicle weight, which in turn improves fuel economy and reduces carbon emissions. Additionally, their recyclability makes them an attractive option for manufacturers aiming to meet environmental regulations. The construction industry also benefits from these composites, particularly in applications requiring high strength and durability, such as bridge components, roofing, and cladding. Their resistance to corrosion and environmental degradation makes them ideal for use in harsh environments. In the sports and leisure industry, these composites are used to manufacture equipment such as bicycles, tennis rackets, and golf clubs, where performance and weight are critical factors. The medical field is another area where these composites are making an impact, particularly in the production of prosthetics and orthotic devices. The ability to customize the material properties allows for the creation of lightweight, durable, and comfortable devices that improve patient outcomes. Furthermore, the electronics industry utilizes these composites in the production of lightweight and durable casings for devices such as laptops and smartphones. The versatility and adaptability of continuous fiber reinforced thermoplastic composites make them suitable for a wide range of applications, driving their demand across various sectors. As industries continue to innovate and seek sustainable solutions, the applications of these composites are expected to expand, offering new opportunities for growth and development.

Global Continuous Fiber Reinforced Thermoplastic Composites Sales Market Outlook:

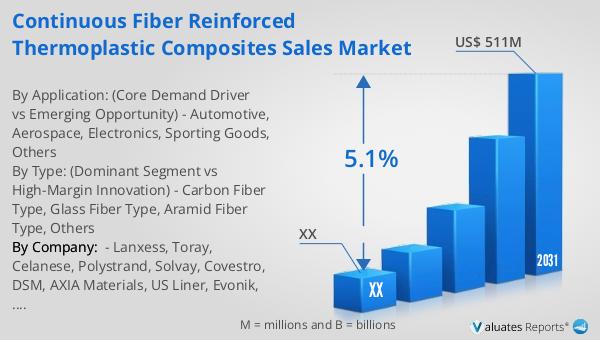

In 2024, the global market for Continuous Fiber Reinforced Thermoplastic Composites was valued at approximately $363 million. By 2031, it is projected to reach an adjusted size of around $511 million, reflecting a compound annual growth rate (CAGR) of 5.1% during the forecast period from 2025 to 2031. The market is characterized by a competitive landscape, with the top four players accounting for about 38% of the total global market share. Among the various types of composites, the Glass Fiber Type is the most prominent, holding a substantial share of approximately 85%. This dominance is attributed to the cost-effectiveness and favorable mechanical properties of glass fiber composites, making them a preferred choice for a wide range of applications. The market's growth is driven by the increasing demand for lightweight and high-performance materials across various industries, including aerospace, automotive, and construction. As these industries continue to prioritize sustainability and efficiency, the demand for continuous fiber reinforced thermoplastic composites is expected to rise, offering innovative solutions for modern engineering challenges. The market's expansion is also supported by advancements in manufacturing technologies, which enable more cost-effective and scalable production processes. Overall, the Global Continuous Fiber Reinforced Thermoplastic Composites Sales Market represents a dynamic and evolving field with significant potential for future development.

| Report Metric | Details |

| Report Name | Continuous Fiber Reinforced Thermoplastic Composites Sales Market |

| Forecasted market size in 2031 | US$ 511 million |

| CAGR | 5.1% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Lanxess, Toray, Celanese, Polystrand, Solvay, Covestro, DSM, AXIA Materials, US Liner, Evonik, SABIC, Teijin, QIYI Tech, Guangzhou Kingfa Carbon Fiber, Zhejiang Suijin Composite Materials, CIMC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |