What is Global Composite LPG Cylinders Sales Market?

The Global Composite LPG Cylinders Sales Market refers to the worldwide trade and distribution of liquefied petroleum gas (LPG) cylinders made from composite materials. These cylinders are an innovative alternative to traditional steel cylinders, offering several advantages such as being lightweight, corrosion-resistant, and having a higher safety profile. Composite LPG cylinders are made from materials like fiberglass and resin, which make them significantly lighter than their steel counterparts, thus easier to handle and transport. This market has been growing steadily due to the increasing demand for safer and more efficient energy storage solutions. The adoption of composite LPG cylinders is particularly strong in regions where safety standards are stringent and where there is a high demand for portable energy solutions, such as in camping, outdoor activities, and in areas with limited access to natural gas pipelines. The market is driven by factors such as the rising awareness of the benefits of composite materials, the need for sustainable and eco-friendly energy solutions, and the growing demand for LPG in residential, commercial, and industrial applications. As more countries and industries recognize the advantages of composite LPG cylinders, the market is expected to continue its upward trajectory, offering significant opportunities for manufacturers and suppliers worldwide.

in the Global Composite LPG Cylinders Sales Market:

Composite LPG cylinders come in various types, each designed to meet the specific needs of different customers. One of the most common types is the Type 4 composite cylinder, which is made entirely of composite materials, including a polymer liner and a composite overwrap. These cylinders are extremely lightweight, making them ideal for applications where portability is crucial, such as in recreational vehicles, boats, and outdoor cooking. Another type is the Type 3 composite cylinder, which features a metal liner wrapped in composite materials. This design offers a balance between weight reduction and durability, making it suitable for both residential and commercial use. Type 3 cylinders are often used in applications where the cylinder needs to withstand higher pressures or more rugged handling conditions. Additionally, there are Type 2 composite cylinders, which have a metal liner and a partial composite wrap. These cylinders are less common but are used in specific applications where a combination of metal and composite materials is desired for added strength and safety. Customers in the Global Composite LPG Cylinders Sales Market choose these different types based on factors such as weight, durability, safety, and cost. For instance, residential customers may prefer Type 4 cylinders for their lightweight and easy handling, while industrial customers might opt for Type 3 cylinders for their robustness and ability to handle higher pressures. The choice of cylinder type also depends on the regulatory requirements in different regions, as some countries have specific standards for LPG cylinder materials and construction. In addition to the basic types, composite LPG cylinders also come in various sizes and capacities to cater to different customer needs. Smaller cylinders, such as those used for camping stoves or portable heaters, typically have capacities ranging from 5 to 15 kilograms. These are popular among outdoor enthusiasts and are often designed with features like ergonomic handles and easy-to-use valves for convenience. Larger cylinders, used in residential or commercial settings, can have capacities of up to 50 kilograms or more, providing a longer-lasting supply of LPG for cooking, heating, or industrial processes. The versatility of composite LPG cylinders in terms of size and capacity makes them suitable for a wide range of applications, from small-scale personal use to large-scale industrial operations. Another important aspect of the Global Composite LPG Cylinders Sales Market is the customization options available to customers. Manufacturers often offer cylinders with various features such as transparent bodies for easy monitoring of gas levels, UV-resistant coatings for outdoor use, and safety features like pressure relief valves and anti-burst technology. These customizations enhance the usability and safety of composite LPG cylinders, making them more appealing to customers with specific needs or preferences. For example, a customer in a region with high UV exposure might opt for a cylinder with a UV-resistant coating to ensure longevity and performance. Similarly, a customer concerned about safety might choose a cylinder with advanced safety features to minimize the risk of accidents. The availability of these customization options allows customers to select composite LPG cylinders that best suit their individual requirements, further driving the growth of the market. Overall, the various types of composite LPG cylinders available in the market cater to a diverse range of customer needs, from lightweight and portable options for outdoor enthusiasts to robust and durable solutions for industrial users. The choice of cylinder type is influenced by factors such as weight, durability, safety, cost, regulatory requirements, and customization options, allowing customers to find the perfect solution for their specific applications. As the demand for safer, more efficient, and environmentally friendly energy storage solutions continues to grow, the Global Composite LPG Cylinders Sales Market is expected to expand, offering a wide array of options for customers worldwide.

in the Global Composite LPG Cylinders Sales Market:

Composite LPG cylinders are used in a variety of applications across different sectors, thanks to their lightweight, durable, and safe design. One of the primary applications is in the residential sector, where these cylinders are used for cooking and heating purposes. In many households, especially in regions without access to natural gas pipelines, LPG cylinders serve as a vital source of energy for daily cooking needs. The lightweight nature of composite cylinders makes them easy to handle and transport, which is particularly beneficial for households that need to frequently replace or refill their gas supply. Additionally, the safety features of composite cylinders, such as pressure relief valves and anti-burst technology, provide peace of mind to users, making them a preferred choice for residential applications. In the commercial sector, composite LPG cylinders are widely used in restaurants, hotels, and catering services for cooking and heating. The hospitality industry often requires a reliable and efficient energy source to meet the high demands of food preparation and service. Composite cylinders, with their lightweight and durable design, offer a practical solution for commercial kitchens that need to frequently move and replace gas cylinders. Moreover, the safety features of composite cylinders are crucial in commercial settings, where the risk of accidents must be minimized to ensure the safety of staff and customers. The industrial sector also benefits from the use of composite LPG cylinders, particularly in applications that require portable and efficient energy solutions. Industries such as construction, manufacturing, and agriculture often use LPG cylinders for tasks like metal cutting, welding, and powering machinery. The lightweight and corrosion-resistant properties of composite cylinders make them ideal for use in harsh industrial environments, where traditional steel cylinders may be prone to damage or degradation. Furthermore, the ability to customize composite cylinders with features like UV-resistant coatings and advanced safety mechanisms enhances their suitability for industrial applications. In addition to these sectors, composite LPG cylinders are also used in recreational and outdoor activities. For example, campers, hikers, and outdoor enthusiasts often rely on portable LPG cylinders for cooking and heating during their adventures. The lightweight and easy-to-carry design of composite cylinders makes them a popular choice for outdoor use, where portability and convenience are key considerations. Moreover, the transparent bodies of some composite cylinders allow users to easily monitor gas levels, ensuring they have enough fuel for their outdoor activities. The versatility of composite LPG cylinders extends to emergency and disaster relief situations as well. In areas affected by natural disasters or other emergencies, access to reliable energy sources can be critical for survival and recovery efforts. Composite cylinders, with their lightweight and durable design, can be quickly deployed to provide essential energy for cooking, heating, and lighting in affected areas. Their safety features also make them a suitable choice for use in challenging and unpredictable environments, where the risk of accidents must be minimized. Overall, the diverse applications of composite LPG cylinders across residential, commercial, industrial, recreational, and emergency sectors highlight their versatility and practicality as an energy storage solution. The lightweight, durable, and safe design of composite cylinders makes them an attractive option for a wide range of uses, from everyday household cooking to large-scale industrial operations. As the demand for efficient and environmentally friendly energy solutions continues to grow, the Global Composite LPG Cylinders Sales Market is expected to expand, offering even more opportunities for the use of composite cylinders in various applications worldwide.

Global Composite LPG Cylinders Sales Market Outlook:

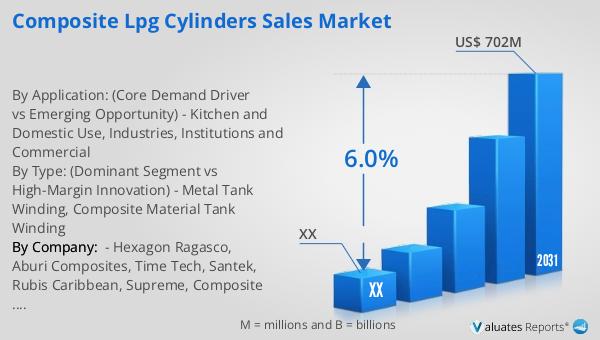

In 2024, the global market for Composite LPG Cylinders was valued at approximately $469 million. Looking ahead, it is projected to grow to an adjusted size of around $702 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.0% during the forecast period from 2025 to 2031. This growth indicates a robust demand for composite LPG cylinders, driven by their advantages over traditional steel cylinders, such as being lighter, more durable, and safer. The market is characterized by a significant concentration of production, with the top five manufacturers accounting for about 60% of the total market share. This concentration suggests that a few key players dominate the market, likely due to their established expertise, production capabilities, and distribution networks. The growth in market size and the dominance of leading manufacturers highlight the increasing acceptance and adoption of composite LPG cylinders across various regions and industries. As more consumers and businesses recognize the benefits of these innovative cylinders, the market is poised for continued expansion. The projected growth also underscores the importance of ongoing research and development in composite materials and manufacturing processes, as companies strive to enhance the performance, safety, and cost-effectiveness of their products. Overall, the outlook for the Global Composite LPG Cylinders Sales Market is positive, with significant opportunities for growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Composite LPG Cylinders Sales Market |

| Forecasted market size in 2031 | US$ 702 million |

| CAGR | 6.0% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Hexagon Ragasco, Aburi Composites, Time Tech, Santek, Rubis Caribbean, Supreme, Composite Scandinavia, Gavenplast, RAD SANE HIDAJ, Sundarban Industrial Complex, Kolos, Metal Mate, EVAS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |