What is Global Cold Forging Machine Sales Market?

The Global Cold Forging Machine Sales Market is a dynamic and essential segment of the manufacturing industry, focusing on the production and sale of machines used for cold forging processes. Cold forging is a metal shaping technique performed at or near room temperature, which enhances the strength and durability of the metal by altering its structure. This market encompasses a wide range of machinery designed to meet the diverse needs of industries such as automotive, aerospace, and construction. These machines are crucial for producing high-strength components with precise dimensions and excellent surface finishes. The market is driven by the increasing demand for lightweight and high-strength materials, particularly in the automotive and aerospace sectors, where efficiency and performance are paramount. As industries continue to seek cost-effective and sustainable manufacturing solutions, the Global Cold Forging Machine Sales Market is poised for growth, offering advanced technologies and innovative solutions to meet evolving industry requirements. The market's expansion is further supported by technological advancements, which enhance machine efficiency and reduce operational costs, making cold forging an attractive option for manufacturers worldwide.

in the Global Cold Forging Machine Sales Market:

The Global Cold Forging Machine Sales Market offers a variety of machine types tailored to meet the specific needs of different customers. These machines are categorized based on their design, functionality, and the number of die stations they possess. One of the most common types is the multi-station cold forging machine, which is highly versatile and capable of producing complex parts with multiple stages of deformation. This type is particularly favored in industries requiring high-volume production, such as automotive and aerospace, due to its efficiency and precision. Another popular type is the single-station cold forging machine, which is ideal for simpler, less complex parts. These machines are often used by smaller manufacturers or in applications where the production volume is lower. Additionally, there are specialized cold forging machines designed for specific applications, such as those used in the production of fasteners, bearings, and other precision components. These machines are equipped with advanced features to ensure high accuracy and consistency in the final product. The choice of machine type is largely influenced by the specific requirements of the customer, including the complexity of the parts to be produced, the desired production volume, and the available budget. For instance, a manufacturer in the automotive industry may opt for a multi-station machine to efficiently produce large quantities of complex components, while a smaller manufacturer may choose a single-station machine for its cost-effectiveness and simplicity. Furthermore, advancements in technology have led to the development of hybrid cold forging machines, which combine the benefits of cold forging with other processes such as machining or heat treatment. These machines offer enhanced flexibility and can produce parts with superior mechanical properties. As the demand for high-performance materials continues to grow, the Global Cold Forging Machine Sales Market is expected to see an increase in the adoption of these advanced machine types. In summary, the market offers a diverse range of cold forging machines, each designed to meet the unique needs of different customers, from high-volume producers to specialized manufacturers seeking precision and efficiency.

in the Global Cold Forging Machine Sales Market:

The Global Cold Forging Machine Sales Market serves a wide array of applications across various industries, each benefiting from the unique advantages of cold forging technology. One of the primary applications is in the automotive industry, where cold forging machines are used to produce critical components such as gears, shafts, and fasteners. These components require high strength and precision, making cold forging an ideal manufacturing process. The aerospace industry also relies heavily on cold forging machines to produce lightweight yet strong components that can withstand extreme conditions. In this sector, cold forging is used to manufacture parts such as turbine blades, landing gear components, and structural elements. The construction industry is another significant user of cold forging machines, utilizing them to produce durable and reliable components like bolts, nuts, and connectors. These components are essential for ensuring the safety and stability of buildings and infrastructure. Additionally, the electronics industry benefits from cold forging technology, particularly in the production of heat sinks and other thermal management components. Cold forging allows for the efficient production of these components with excellent thermal conductivity and structural integrity. Furthermore, the medical industry is increasingly adopting cold forging machines to produce high-precision components for medical devices and implants. The ability to produce complex shapes with tight tolerances makes cold forging an attractive option for manufacturers in this field. Overall, the Global Cold Forging Machine Sales Market plays a crucial role in supporting a wide range of applications, providing industries with the tools they need to produce high-quality, reliable components. As industries continue to evolve and demand more advanced materials and manufacturing processes, the market is expected to expand, offering innovative solutions to meet the diverse needs of its customers.

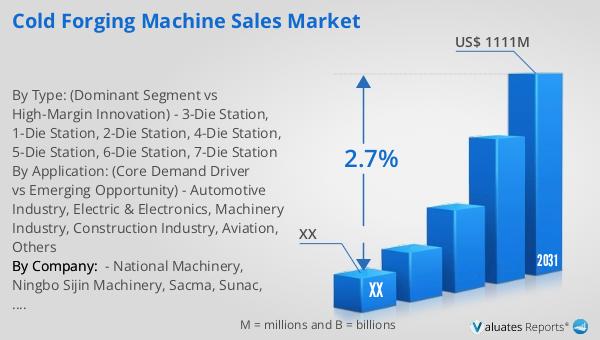

Global Cold Forging Machine Sales Market Outlook:

In 2024, the global Cold Forging Machine market was valued at approximately US$ 927 million, and projections indicate that by 2031, it will reach an adjusted size of around US$ 1111 million. This growth is expected to occur at a compound annual growth rate (CAGR) of 2.7% during the forecast period from 2025 to 2031. The market is characterized by a competitive landscape, with the top five players collectively holding about 40% of the market share. Among the various product types, the 5-Die Station segment stands out as the largest, accounting for approximately 22% of the market share. This segment's prominence is attributed to its efficiency and capability to produce complex parts with high precision. In terms of application, the automotive industry is a major contributor, holding a share of about 24%. This is due to the industry's continuous demand for high-strength, lightweight components that enhance vehicle performance and fuel efficiency. The market's steady growth reflects the increasing adoption of cold forging technology across various industries, driven by the need for cost-effective and sustainable manufacturing solutions. As industries continue to prioritize efficiency and innovation, the Global Cold Forging Machine Sales Market is poised to play a pivotal role in shaping the future of manufacturing.

| Report Metric | Details |

| Report Name | Cold Forging Machine Sales Market |

| Forecasted market size in 2031 | US$ 1111 million |

| CAGR | 2.7% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | National Machinery, Ningbo Sijin Machinery, Sacma, Sunac, Hyodong, Jern Yao, Komatsu, Chun Zu Machinery, Nedschroef, Sakamura, Hatebur, Nakashimada, Aida, Dongrui Machinery, Chin Fong Machine, Qunfeng Machinery, Yeswin Machinery, GFM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |