What is Global CNC Metal Cutting Machine Tools Sales Market?

The Global CNC Metal Cutting Machine Tools Sales Market refers to the worldwide industry focused on the production, distribution, and sale of CNC (Computer Numerical Control) metal cutting machines. These machines are essential in the manufacturing sector as they automate the process of cutting metal into precise shapes and sizes, which is crucial for producing components used in various industries such as automotive, aerospace, and construction. The market encompasses a wide range of CNC machines, including lathes, mills, routers, and grinders, each designed to perform specific cutting tasks with high precision and efficiency. The demand for CNC metal cutting machines is driven by the need for high-quality, accurate, and efficient manufacturing processes. As industries continue to evolve and require more complex and precise components, the market for these machines is expected to grow. Additionally, advancements in technology, such as the integration of AI and IoT in CNC machines, are further propelling the market by enhancing the capabilities and efficiency of these tools. The global reach of this market indicates its significance in the modern manufacturing landscape, providing essential tools that enable industries to meet the demands of a rapidly changing world.

in the Global CNC Metal Cutting Machine Tools Sales Market:

The Global CNC Metal Cutting Machine Tools Sales Market is diverse, with various types of machines catering to different customer needs. CNC Lathes are one of the most popular types, accounting for over 30% of the market share. These machines are primarily used for shaping metal by rotating the workpiece against a cutting tool, making them ideal for producing cylindrical parts like shafts and pulleys. CNC Milling Machines are another significant type, used for cutting and drilling tasks. They are versatile and can handle complex shapes, making them suitable for industries that require intricate designs, such as aerospace and automotive. CNC Routers are designed for cutting softer materials like wood and plastic but are also used for metal cutting in some applications. They are favored for their ability to produce detailed and precise cuts, making them popular in the furniture and signage industries. CNC Grinders are used for finishing processes, providing a smooth surface finish to metal parts. These machines are essential in industries where precision and surface quality are critical, such as in the production of bearings and gears. Another type is CNC Plasma Cutters, which use a high-velocity jet of ionized gas to cut through metal. They are commonly used in industries that require fast and efficient cutting of thick metal sheets, such as shipbuilding and construction. CNC Laser Cutters are similar but use a laser beam for cutting, offering high precision and the ability to cut intricate designs. They are widely used in the electronics and jewelry industries. CNC Waterjet Cutters use a high-pressure stream of water mixed with abrasive materials to cut through metal. They are preferred for their ability to cut without generating heat, which is crucial for materials sensitive to high temperatures. Each type of CNC machine offers unique advantages, and the choice of machine depends on the specific requirements of the customer, such as the type of material to be cut, the desired precision, and the production volume. As technology advances, these machines are becoming more sophisticated, offering enhanced capabilities and efficiency, which in turn is driving their adoption across various industries.

in the Global CNC Metal Cutting Machine Tools Sales Market:

The applications of Global CNC Metal Cutting Machine Tools are vast and varied, spanning multiple industries that rely on precision and efficiency in manufacturing. In the automotive industry, CNC machines are used to produce a wide range of components, from engine parts to body panels. The precision offered by CNC machines ensures that each part meets the stringent quality standards required in the automotive sector. In the aerospace industry, CNC machines are indispensable for manufacturing complex components such as turbine blades and structural parts. The high precision and repeatability of CNC machines are crucial in this industry, where even the smallest deviation can have significant consequences. The construction industry also benefits from CNC machines, particularly in the production of metal frameworks and structural components. The ability to cut and shape metal with high precision allows for the creation of complex structures that are both strong and aesthetically pleasing. In the electronics industry, CNC machines are used to produce intricate components such as circuit boards and connectors. The precision and accuracy of CNC machines are essential in this industry, where even the smallest error can affect the performance of the final product. The medical industry also relies on CNC machines for the production of surgical instruments and implants. The high precision and quality offered by CNC machines ensure that these critical components meet the stringent standards required in the medical field. Additionally, the jewelry industry uses CNC machines to create intricate designs and patterns, allowing for the production of high-quality pieces with consistent precision. The versatility and efficiency of CNC machines make them an essential tool in modern manufacturing, enabling industries to produce high-quality components with precision and efficiency. As technology continues to advance, the applications of CNC machines are expected to expand further, driving innovation and growth in various sectors.

Global CNC Metal Cutting Machine Tools Sales Market Outlook:

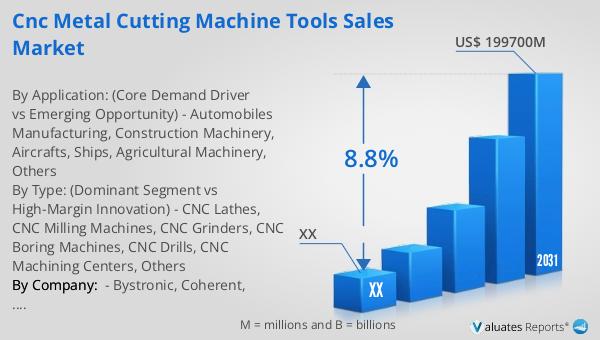

The global CNC Metal Cutting Machine Tools market is projected to experience significant growth in the coming years. In 2024, the market size was valued at approximately US$ 111,560 million. By 2031, it is anticipated to reach an adjusted size of US$ 199,700 million, reflecting a compound annual growth rate (CAGR) of 8.8% during the forecast period from 2025 to 2031. This growth is indicative of the increasing demand for CNC metal cutting machines across various industries. Among the different types of CNC machines, CNC Lathes hold the largest market segment, accounting for over 30% of the total market share. This dominance can be attributed to their widespread use in industries that require the production of cylindrical parts with high precision and efficiency. The growing adoption of CNC Lathes is driven by their ability to automate the manufacturing process, reduce production time, and improve the quality of the final product. As industries continue to seek ways to enhance productivity and maintain competitive advantage, the demand for CNC metal cutting machines is expected to rise. The market's growth is further supported by technological advancements, such as the integration of artificial intelligence and the Internet of Things (IoT) in CNC machines, which enhance their capabilities and efficiency. These advancements are likely to attract more industries to adopt CNC machines, thereby contributing to the market's expansion. Overall, the global CNC Metal Cutting Machine Tools market is poised for robust growth, driven by increasing demand, technological advancements, and the need for precision and efficiency in manufacturing processes.

| Report Metric | Details |

| Report Name | CNC Metal Cutting Machine Tools Sales Market |

| Forecasted market size in 2031 | US$ 199700 million |

| CAGR | 8.8% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Bystronic, Coherent, Colfax, Komatsu, Nissan Tanaka, Trumpf, Yamazaki Mazak, DMG Mori Seiki, AMADA, Okuma Corporation, Schuler, GF Machining Solutions, Haas Automation, Emag |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |