What is Global CMP Polishing Slurry Market?

The Global CMP Polishing Slurry Market is a crucial component in the semiconductor manufacturing industry, playing a vital role in the chemical mechanical planarization (CMP) process. CMP is a technique used to smooth and flatten surfaces at the microscopic level, which is essential for producing high-performance semiconductor devices. The slurry, a mixture of abrasive particles and chemicals, is used to polish wafers, ensuring that they meet the stringent specifications required for advanced electronic components. As the demand for smaller, faster, and more efficient electronic devices continues to grow, the need for high-quality CMP polishing slurries has increased. This market is driven by technological advancements in semiconductor manufacturing, the increasing complexity of integrated circuits, and the expansion of the electronics industry globally. The market is characterized by a high level of competition, with several key players striving to innovate and improve their slurry formulations to meet the evolving needs of the semiconductor industry. The Global CMP Polishing Slurry Market is expected to continue its growth trajectory, driven by the ongoing demand for advanced electronic devices and the continuous evolution of semiconductor technology.

Alumina CMP Slurry, Colloidal Silica CMP Slurry, Ceria CMP Slurries in the Global CMP Polishing Slurry Market:

Alumina CMP Slurry, Colloidal Silica CMP Slurry, and Ceria CMP Slurries are three primary types of slurries used in the Global CMP Polishing Slurry Market, each with unique properties and applications. Alumina CMP Slurry is known for its high hardness and abrasive properties, making it suitable for polishing hard materials like silicon carbide and sapphire. It is often used in applications where a high removal rate is required, such as in the planarization of hard substrates. The alumina particles in the slurry are typically suspended in a chemical solution that helps to enhance the polishing process by chemically reacting with the surface being polished. This type of slurry is favored for its ability to achieve a high degree of planarity and surface smoothness, which are critical for the performance of semiconductor devices.

Silicon Wafer & IC CMP Slurry, SiC Wafer, Optical Substrates, Disk-drive Components, Others in the Global CMP Polishing Slurry Market:

Colloidal Silica CMP Slurry, on the other hand, is characterized by its smaller particle size and lower hardness compared to alumina slurries. This makes it ideal for polishing softer materials and achieving a high level of surface smoothness. Colloidal silica slurries are widely used in the semiconductor industry for polishing silicon wafers and other delicate substrates. The small particle size allows for precise control over the polishing process, resulting in a smooth and defect-free surface. Additionally, colloidal silica slurries are often used in applications where a high degree of selectivity is required, such as in the polishing of multi-layered structures. The chemical composition of the slurry can be tailored to enhance its performance for specific applications, making it a versatile choice for a wide range of polishing tasks.

Global CMP Polishing Slurry Market Outlook:

Ceria CMP Slurries are another important type of slurry used in the Global CMP Polishing Slurry Market. Ceria, or cerium oxide, is known for its unique chemical and mechanical properties, which make it highly effective for polishing applications that require a high degree of precision and surface quality. Ceria slurries are commonly used in the polishing of glass and other optical materials, where achieving a high level of clarity and smoothness is essential. The ceria particles in the slurry chemically interact with the surface being polished, facilitating the removal of material and the creation of a smooth, defect-free surface. This type of slurry is particularly valued for its ability to achieve a high level of surface quality with minimal defects, making it a preferred choice for applications in the optics and electronics industries.

| Report Metric | Details |

| Report Name | CMP Polishing Slurry Market |

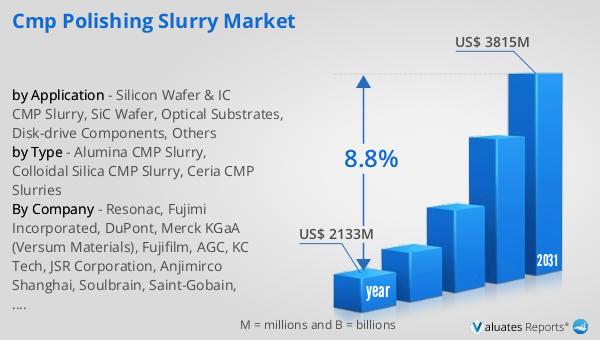

| Accounted market size in year | US$ 2133 million |

| Forecasted market size in 2031 | US$ 3815 million |

| CAGR | 8.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Resonac, Fujimi Incorporated, DuPont, Merck KGaA (Versum Materials), Fujifilm, AGC, KC Tech, JSR Corporation, Anjimirco Shanghai, Soulbrain, Saint-Gobain, TOPPAN INFOMEDIA, Ace Nanochem, Dongjin Semichem, Vibrantz (Ferro), WEC Group, SKC (SK Enpulse), Shanghai Xinanna Electronic Technology, Hubei Dinglong, Beijing Hangtian Saide, Engis Corporation, Shenzhen Angshite Technology, CHUANYAN, Samsung SDI, Zhuhai Cornerstone Technologies, Zhejiang Bolai Narun Electronic Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |