What is Global Additive Manufacturing with Metal Powders Sales Market?

Global Additive Manufacturing with Metal Powders Sales Market refers to the industry focused on the production and sale of metal powders used in additive manufacturing, commonly known as 3D printing. This market is a crucial segment of the broader additive manufacturing industry, which involves creating three-dimensional objects from digital files by layering materials. Metal powders, such as titanium, aluminum, and stainless steel, are essential for producing high-strength, durable components in various industries, including aerospace, automotive, and healthcare. The market's growth is driven by the increasing demand for lightweight, complex, and customized parts that traditional manufacturing methods cannot easily produce. As technology advances, the efficiency and capabilities of additive manufacturing with metal powders continue to improve, making it an attractive option for manufacturers seeking to innovate and optimize their production processes. The market is characterized by a diverse range of players, from large multinational corporations to specialized startups, all competing to develop new materials and technologies that enhance the performance and cost-effectiveness of metal additive manufacturing. As a result, the Global Additive Manufacturing with Metal Powders Sales Market is poised for significant growth in the coming years, driven by technological advancements and the expanding adoption of 3D printing across various industries.

in the Global Additive Manufacturing with Metal Powders Sales Market:

In the Global Additive Manufacturing with Metal Powders Sales Market, various types of metal powders are utilized by customers depending on their specific needs and applications. One of the most popular types is titanium powder, known for its excellent strength-to-weight ratio and corrosion resistance. This makes it ideal for aerospace and medical applications, where lightweight and durable materials are crucial. Aluminum powder is another widely used type, valued for its lightweight properties and high thermal conductivity, making it suitable for automotive and aerospace components. Stainless steel powder is favored for its strength, durability, and resistance to wear and corrosion, making it a versatile choice for a wide range of industries, including automotive, aerospace, and consumer goods. Nickel-based superalloy powders are also significant in this market, particularly in the aerospace and energy sectors, where high-temperature resistance and strength are essential. These powders are used to produce turbine blades, engine components, and other critical parts that must withstand extreme conditions. Copper powder is another type used in additive manufacturing, prized for its excellent electrical and thermal conductivity. It is commonly used in the electronics industry for producing components like heat exchangers and electrical connectors. Cobalt-chrome powders are also notable, especially in the medical and dental fields, where biocompatibility and strength are required for implants and prosthetics. The choice of metal powder depends on several factors, including the desired properties of the final product, the specific requirements of the application, and the cost considerations. As the technology and materials continue to evolve, the range of available metal powders is expected to expand, offering even more options for manufacturers to tailor their products to meet the demands of various industries. This diversity in metal powders allows for greater flexibility and innovation in design and manufacturing, enabling companies to produce complex geometries and customized parts that were previously unattainable with traditional manufacturing methods. As a result, the Global Additive Manufacturing with Metal Powders Sales Market is characterized by a dynamic and competitive landscape, with companies continually seeking to develop new materials and processes that enhance the capabilities and applications of metal additive manufacturing.

in the Global Additive Manufacturing with Metal Powders Sales Market:

The Global Additive Manufacturing with Metal Powders Sales Market finds applications across a wide range of industries, each leveraging the unique advantages of metal additive manufacturing to enhance their products and processes. In the aerospace industry, additive manufacturing with metal powders is used to produce lightweight, complex components that reduce fuel consumption and improve performance. Parts such as turbine blades, engine components, and structural elements benefit from the design flexibility and material efficiency offered by 3D printing. The automotive industry also utilizes metal additive manufacturing to create lightweight parts that enhance fuel efficiency and reduce emissions. Components like engine parts, exhaust systems, and structural elements can be optimized for performance and weight, contributing to the development of more sustainable vehicles. In the medical field, additive manufacturing with metal powders is revolutionizing the production of implants and prosthetics. The ability to create customized, patient-specific implants with complex geometries improves the fit and function of medical devices, leading to better patient outcomes. Dental applications also benefit from metal additive manufacturing, with the production of crowns, bridges, and orthodontic appliances tailored to individual patients. The energy sector is another significant user of metal additive manufacturing, particularly in the production of components for gas turbines and other high-temperature applications. The ability to produce parts with intricate cooling channels and optimized geometries enhances the efficiency and performance of energy systems. Additionally, the electronics industry leverages metal additive manufacturing for the production of components like heat exchangers and electrical connectors, where the excellent thermal and electrical conductivity of metal powders is advantageous. The versatility and precision of metal additive manufacturing make it an attractive option for industries seeking to innovate and improve their products. As the technology continues to advance, the range of applications is expected to expand, offering new opportunities for manufacturers to enhance their products and processes. The Global Additive Manufacturing with Metal Powders Sales Market is poised for significant growth as more industries recognize the benefits of 3D printing and adopt it as a key component of their manufacturing strategies.

Global Additive Manufacturing with Metal Powders Sales Market Outlook:

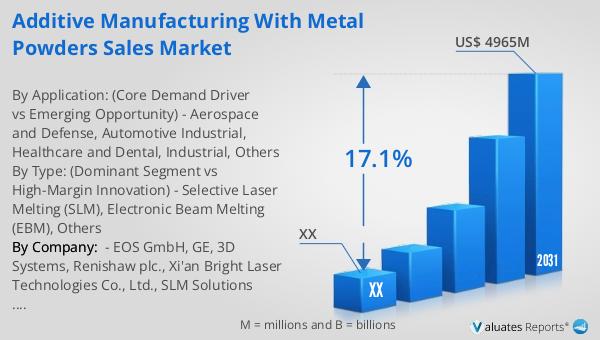

In 2024, the global market for Additive Manufacturing with Metal Powders was valued at approximately $1,669 million. Looking ahead, it is projected to grow significantly, reaching an estimated $4,965 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 17.1% during the forecast period from 2025 to 2031. The market is dominated by the top five manufacturers, who collectively hold a market share exceeding 40%. Geographically, Europe emerges as the largest market, accounting for over 35% of the global share. Following closely are the Asia-Pacific and North American regions, which together represent about 60% of the market share. In terms of product segments, Selective Laser Melting (SLM) stands out as the largest, capturing over 70% of the market share. This data highlights the dynamic nature of the Global Additive Manufacturing with Metal Powders Sales Market, driven by technological advancements and increasing adoption across various industries. The significant growth potential and competitive landscape underscore the importance of innovation and strategic positioning for companies operating in this market. As the demand for lightweight, complex, and customized components continues to rise, the market is expected to witness further expansion and development in the coming years.

| Report Metric | Details |

| Report Name | Additive Manufacturing with Metal Powders Sales Market |

| Forecasted market size in 2031 | US$ 4965 million |

| CAGR | 17.1% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | EOS GmbH, GE, 3D Systems, Renishaw plc., Xi'an Bright Laser Technologies Co., Ltd., SLM Solutions Group AG, Huake 3D, ExOne, Shining 3D Tech Co., Ltd., Syndaya |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |