What is Global 3D Printing & Additive Manufacturing in the Aerospace & Defence Sales Market?

Global 3D Printing and Additive Manufacturing in the Aerospace and Defence Sales Market is a rapidly evolving sector that leverages advanced technologies to create complex components and systems used in aircraft, spacecraft, and defense equipment. This market focuses on the use of 3D printing, also known as additive manufacturing, which involves creating three-dimensional objects by layering materials based on digital models. This innovative approach allows for the production of lightweight, durable, and highly customized parts that are essential in aerospace and defense applications. The technology is particularly beneficial in reducing material waste, lowering production costs, and shortening the time required to develop and manufacture parts. As the aerospace and defense industries demand more efficient and sustainable manufacturing processes, the adoption of 3D printing and additive manufacturing continues to grow. Companies in this market are investing in research and development to enhance the capabilities of 3D printing technologies, aiming to improve the performance and reliability of the components produced. This market is characterized by a high level of innovation and collaboration among manufacturers, suppliers, and end-users, driving advancements that are reshaping the future of aerospace and defense manufacturing.

in the Global 3D Printing & Additive Manufacturing in the Aerospace & Defence Sales Market:

In the Global 3D Printing and Additive Manufacturing in the Aerospace and Defence Sales Market, various types of 3D printing technologies are employed to meet the diverse needs of customers. One of the most widely used types is Fused Deposition Modeling (FDM), which is popular for its cost-effectiveness and ability to produce durable parts. FDM is often used for prototyping and manufacturing small to medium-sized components. Another prevalent type is Stereolithography (SLA), known for its precision and ability to produce highly detailed parts. SLA is particularly useful for creating complex geometries and is often used in the production of intricate aerospace components. Selective Laser Sintering (SLS) is another type that is favored for its ability to produce strong and functional parts from a variety of materials, including metals and polymers. SLS is commonly used in the production of functional prototypes and end-use parts in the aerospace and defense sectors. Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) are advanced types of 3D printing technologies that are specifically used for metal parts. These technologies are essential for producing high-strength, lightweight components that are critical in aerospace and defense applications. DMLS and EBM are often used for manufacturing engine parts, structural components, and other critical elements that require high performance and reliability. Binder Jetting is another type of 3D printing technology that is gaining traction in the aerospace and defense industries. It involves the use of a binding agent to join powder particles, creating parts layer by layer. Binder Jetting is known for its speed and ability to produce large parts, making it suitable for applications where time and size are critical factors. Multi Jet Fusion (MJF) is a relatively new type of 3D printing technology that offers high precision and speed. It is used for producing functional parts with fine details and smooth surfaces, making it ideal for aerospace and defense applications that require high-quality finishes. Each of these 3D printing technologies has its unique advantages and limitations, and the choice of technology depends on the specific requirements of the application, such as material properties, part size, complexity, and production volume. As the Global 3D Printing and Additive Manufacturing in the Aerospace and Defence Sales Market continues to evolve, manufacturers are exploring new materials and processes to enhance the capabilities of these technologies, aiming to meet the growing demands of the aerospace and defense industries.

in the Global 3D Printing & Additive Manufacturing in the Aerospace & Defence Sales Market:

The applications of Global 3D Printing and Additive Manufacturing in the Aerospace and Defence Sales Market are vast and varied, reflecting the diverse needs of these industries. One of the primary applications is in the production of lightweight components, which are crucial for improving fuel efficiency and performance in aircraft and spacecraft. 3D printing allows for the creation of complex geometries that are not possible with traditional manufacturing methods, enabling the production of parts that are both strong and lightweight. This is particularly important in the aerospace industry, where reducing weight can lead to significant cost savings and environmental benefits. Another key application is in the production of customized parts and components. 3D printing enables manufacturers to produce parts that are tailored to specific requirements, allowing for greater flexibility and customization in design. This is especially valuable in the defense sector, where equipment often needs to be adapted to meet the unique needs of different missions and environments. 3D printing also plays a critical role in the rapid prototyping and testing of new designs. The ability to quickly produce and test prototypes allows manufacturers to iterate and refine designs more efficiently, reducing the time and cost associated with bringing new products to market. This is particularly beneficial in the aerospace and defense industries, where innovation and speed are key competitive advantages. Additionally, 3D printing is used in the production of spare parts and maintenance components. The ability to produce parts on-demand reduces the need for large inventories and allows for more efficient supply chain management. This is especially important in the aerospace industry, where downtime can be costly and having the right parts available when needed is critical. Furthermore, 3D printing is increasingly being used in the production of tooling and fixtures, which are essential for the manufacturing process. The ability to quickly produce custom tools and fixtures allows manufacturers to optimize their production processes and improve efficiency. As the Global 3D Printing and Additive Manufacturing in the Aerospace and Defence Sales Market continues to grow, new applications are emerging, driven by advancements in technology and materials. Manufacturers are exploring new ways to leverage 3D printing to improve performance, reduce costs, and enhance the capabilities of aerospace and defense systems.

Global 3D Printing & Additive Manufacturing in the Aerospace & Defence Sales Market Outlook:

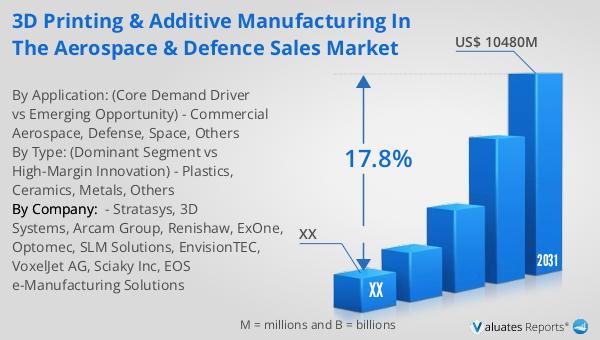

The global market for 3D Printing and Additive Manufacturing in the Aerospace and Defence sector is poised for significant growth. In 2024, the market size was valued at approximately US$ 3,379 million, and it is projected to expand to an adjusted size of US$ 10,480 million by 2031, reflecting a robust compound annual growth rate (CAGR) of 17.8% during the forecast period from 2025 to 2031. The market is dominated by the top five manufacturers, who collectively hold a substantial share of over 70%. Geographically, North America leads the market with a share exceeding 35%, followed closely by Europe and the Asia-Pacific region, which together account for over 45% of the market share. In terms of product segments, plastics material emerges as the largest segment, commanding a share of over 45%. This growth trajectory underscores the increasing adoption of 3D printing technologies in the aerospace and defense industries, driven by the demand for innovative, efficient, and sustainable manufacturing solutions. As the market continues to evolve, manufacturers are focusing on enhancing their capabilities and expanding their product offerings to meet the diverse needs of the aerospace and defense sectors.

| Report Metric | Details |

| Report Name | 3D Printing & Additive Manufacturing in the Aerospace & Defence Sales Market |

| Forecasted market size in 2031 | US$ 10480 million |

| CAGR | 17.8% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Stratasys, 3D Systems, Arcam Group, Renishaw, ExOne, Optomec, SLM Solutions, EnvisionTEC, VoxelJet AG, Sciaky Inc, EOS e-Manufacturing Solutions |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |