What is Global Magnetic Alloy Powder and Magnetic Core Market?

The Global Magnetic Alloy Powder and Magnetic Core Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries. This market primarily revolves around the production and application of magnetic alloy powders and cores, which are essential components in the manufacturing of electronic devices and systems. Magnetic alloy powders are finely ground materials composed of magnetic metals and alloys, which are used to create magnetic cores. These cores are integral to the functioning of transformers, inductors, and other electromagnetic devices. The market is driven by the increasing demand for energy-efficient and high-performance electronic devices across the globe. As industries continue to innovate and develop new technologies, the need for advanced magnetic materials grows, fueling the expansion of this market. The market's growth is also supported by advancements in material science and manufacturing processes, which enable the production of more efficient and cost-effective magnetic components. Overall, the Global Magnetic Alloy Powder and Magnetic Core Market is poised for significant growth as it continues to meet the demands of various high-tech industries.

MPP, Sendust, High Flux, Fe-Si, Others in the Global Magnetic Alloy Powder and Magnetic Core Market:

MPP (Molypermalloy Powder), Sendust, High Flux, Fe-Si (Iron-Silicon), and other magnetic materials are key components in the Global Magnetic Alloy Powder and Magnetic Core Market. Each of these materials has unique properties that make them suitable for specific applications. MPP is known for its low core loss and high permeability, making it ideal for use in high-frequency applications such as power inductors and transformers. Its ability to maintain stable inductance over a wide range of temperatures and frequencies makes it a preferred choice for many electronic devices. Sendust, on the other hand, is an alloy composed of aluminum, silicon, and iron. It is valued for its low core loss and high saturation magnetization, which makes it suitable for use in power conversion and filtering applications. Sendust cores are often used in applications where low noise and high efficiency are critical. High Flux materials are composed of nickel, iron, and molybdenum, and are known for their high saturation flux density and low core loss. These properties make High Flux materials ideal for use in high-power applications such as inverters and converters. Fe-Si, or Iron-Silicon, is another important material in this market. It is known for its high electrical resistivity and low hysteresis loss, making it suitable for use in transformers and other electromagnetic devices. Fe-Si cores are often used in applications where high efficiency and low energy loss are important. Other materials in this market include amorphous and nanocrystalline alloys, which offer unique properties such as high permeability and low core loss. These materials are often used in advanced applications where traditional materials may not meet the required performance standards. Overall, the diversity of materials available in the Global Magnetic Alloy Powder and Magnetic Core Market allows for a wide range of applications, each with its own set of requirements and challenges.

Photovoltaic, New Energy Vehicles, Household Appliances, UPS, Telecommunication, Others in the Global Magnetic Alloy Powder and Magnetic Core Market:

The Global Magnetic Alloy Powder and Magnetic Core Market finds extensive usage across various sectors, including Photovoltaic, New Energy Vehicles, Household Appliances, UPS (Uninterruptible Power Supply), Telecommunication, and others. In the photovoltaic industry, magnetic cores are used in inverters, which are essential for converting the direct current (DC) generated by solar panels into alternating current (AC) for use in homes and businesses. The efficiency and reliability of these inverters are crucial for maximizing the energy output of solar power systems. In the realm of New Energy Vehicles, magnetic cores are integral to the functioning of electric motors and power electronics, which are key components in electric and hybrid vehicles. The demand for energy-efficient and high-performance magnetic materials is driven by the need to improve the range and efficiency of these vehicles. Household appliances also benefit from the use of magnetic cores, particularly in devices such as refrigerators, air conditioners, and washing machines, where they are used in motors and power supplies to enhance energy efficiency and performance. In the UPS industry, magnetic cores are used in transformers and inductors to ensure a stable and reliable power supply, which is critical for protecting sensitive electronic equipment from power fluctuations and outages. The telecommunication sector relies on magnetic cores for the efficient transmission and reception of signals, as well as for power management in communication devices and infrastructure. Other industries, such as industrial automation and medical equipment, also utilize magnetic cores for various applications, highlighting the versatility and importance of these materials in modern technology. The growing demand for energy-efficient and high-performance electronic devices across these sectors continues to drive the expansion of the Global Magnetic Alloy Powder and Magnetic Core Market.

Global Magnetic Alloy Powder and Magnetic Core Market Outlook:

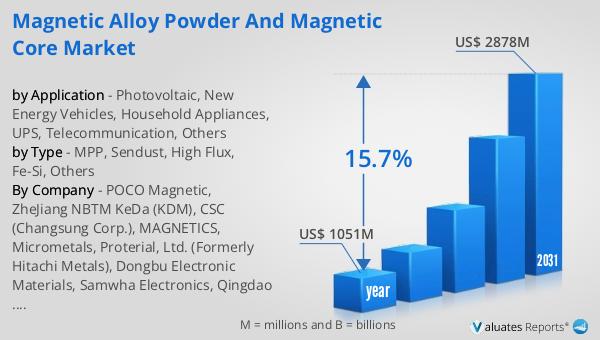

The global market for Magnetic Alloy Powder and Magnetic Core was valued at $1,051 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $2,878 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 15.7% over the forecast period. This impressive growth trajectory underscores the increasing demand for magnetic materials across various industries, driven by the need for energy-efficient and high-performance electronic devices. As industries continue to innovate and develop new technologies, the demand for advanced magnetic materials is expected to rise, further fueling the expansion of this market. The market's growth is also supported by advancements in material science and manufacturing processes, which enable the production of more efficient and cost-effective magnetic components. Overall, the Global Magnetic Alloy Powder and Magnetic Core Market is poised for significant growth as it continues to meet the demands of various high-tech industries.

| Report Metric | Details |

| Report Name | Magnetic Alloy Powder and Magnetic Core Market |

| Accounted market size in year | US$ 1051 million |

| Forecasted market size in 2031 | US$ 2878 million |

| CAGR | 15.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | POCO Magnetic, ZheJiang NBTM KeDa (KDM), CSC (Changsung Corp.), MAGNETICS, Micrometals, Proterial, Ltd. (Formerly Hitachi Metals), Dongbu Electronic Materials, Samwha Electronics, Qingdao Yunlu Advanced Materials, TDG, DMEGC, CMSS Technology, Nanjing New Conda Magnetic, Sinomag Technology, Amogreentech, Advanced Technology & Materials, Epson Atmix, Jiangxi Yuean Advanced Materials, Hunan Hualiu New Materials, Sandvik, Daido Steel, Hoganas, DOWA Electronics Materials, Yahao Materials & Technology, Nopion Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |