What is Blister Packaging Tooling - Global Market?

Blister packaging tooling is a crucial component in the packaging industry, specifically designed for creating blister packs. These packs are commonly used for packaging small consumer goods, pharmaceuticals, and food items. The tooling involves a set of specialized equipment and dies that shape and seal the plastic or aluminum materials into blister packs. The global market for blister packaging tooling is driven by the increasing demand for convenient and tamper-proof packaging solutions. This market encompasses various types of tooling, including forming tools, seal tools, and perforation dies, each playing a vital role in the production process. The growth of this market is attributed to the rising need for efficient packaging solutions that ensure product safety and extend shelf life. As industries continue to innovate and seek sustainable packaging options, the demand for advanced blister packaging tooling is expected to rise, making it a significant area of focus for manufacturers worldwide.

Forming Tools, Seal Tools, Guide Tracks/Rails, Perforation & Scoring Dies, Others in the Blister Packaging Tooling - Global Market:

Blister packaging tooling involves several key components, each serving a specific function in the packaging process. Forming tools are essential for shaping the plastic or aluminum sheets into the desired blister shape. These tools are designed to withstand high temperatures and pressures, ensuring precise and consistent formation of blisters. Seal tools, on the other hand, are used to seal the formed blisters with a backing material, typically made of paperboard or aluminum foil. This sealing process is crucial for maintaining the integrity of the packaged product, preventing contamination and ensuring a secure closure. Guide tracks or rails are another important component, providing a pathway for the blister packs to move through the packaging line. These tracks ensure smooth and accurate movement, reducing the risk of misalignment or damage during the packaging process. Perforation and scoring dies are used to create easy-to-open features on the blister packs, enhancing consumer convenience. These dies are designed to create precise perforations or scores, allowing consumers to easily access the product without compromising the packaging's integrity. Other components in blister packaging tooling may include cutting dies, which are used to trim excess material from the blister packs, and inspection systems, which ensure the quality and consistency of the final product. The global market for blister packaging tooling is driven by the increasing demand for efficient and reliable packaging solutions across various industries. As manufacturers continue to innovate and improve their packaging processes, the need for advanced tooling solutions is expected to grow, making it a key area of focus for the packaging industry.

Thermoform, Cold-form in the Blister Packaging Tooling - Global Market:

Blister packaging tooling is utilized in two primary processes: thermoforming and cold-forming. Thermoforming involves heating a plastic sheet until it becomes pliable, then forming it into the desired shape using a mold. This process is widely used for creating blister packs due to its efficiency and cost-effectiveness. Thermoforming allows for the production of high-quality blister packs with excellent clarity and durability, making it ideal for packaging consumer goods and pharmaceuticals. The tooling used in thermoforming includes forming tools, seal tools, and cutting dies, each playing a crucial role in shaping and sealing the blister packs. Cold-forming, on the other hand, involves shaping aluminum-based materials without the use of heat. This process is typically used for packaging sensitive products that require a high barrier to moisture and oxygen. Cold-forming provides excellent protection for pharmaceuticals and other perishable goods, ensuring their safety and extending their shelf life. The tooling used in cold-forming includes forming tools, seal tools, and perforation dies, each designed to handle the unique properties of aluminum materials. Both thermoforming and cold-forming processes require precise and reliable tooling to ensure the quality and consistency of the final product. As the demand for blister packaging continues to grow, manufacturers are investing in advanced tooling solutions to improve their production processes and meet the evolving needs of consumers.

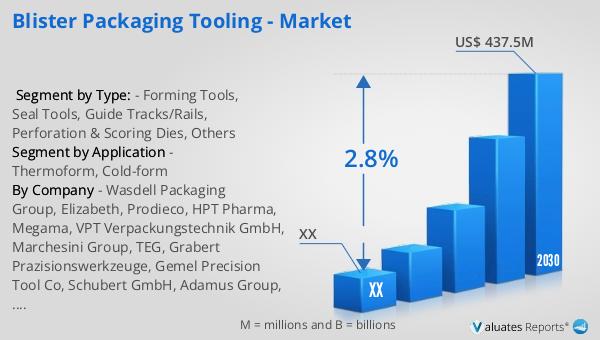

Blister Packaging Tooling - Global Market Outlook:

The global market for blister packaging tooling was valued at approximately $361.6 million in 2023. It is projected to grow to a revised size of $437.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.8% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for efficient and reliable packaging solutions across various industries, including pharmaceuticals, consumer goods, and food. In North America, the market for blister packaging tooling was valued at a significant amount in 2023 and is expected to reach an even higher value by 2030, with a steady CAGR throughout the forecast period. The growth in this region is attributed to the rising demand for convenient and tamper-proof packaging solutions, as well as the increasing focus on sustainability and innovation in packaging processes. As manufacturers continue to invest in advanced tooling solutions, the global market for blister packaging tooling is expected to experience steady growth, making it a key area of focus for the packaging industry.

| Report Metric | Details |

| Report Name | Blister Packaging Tooling - Market |

| Forecasted market size in 2030 | US$ 437.5 million |

| CAGR | 2.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Wasdell Packaging Group, Elizabeth, Prodieco, HPT Pharma, Megama, VPT Verpackungstechnik GmbH, Marchesini Group, TEG, Grabert Prazisionswerkzeuge, Gemel Precision Tool Co, Schubert GmbH, Adamus Group, Borsch Engineering, Inc, Accupack, Prebelli Industries, Thomas Packaging LLC, Dordan Manufacturing, Hangzhou Demei Pharma Technology Co.,Ltd, Toolrite, Forstek D.O.O. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |