What is High Precision Cycloidal Gear - Global Market?

High precision cycloidal gears are specialized mechanical components used in various industries for their unique ability to deliver smooth, precise, and efficient motion control. These gears are characterized by their distinctive design, which involves a cycloidal disc that rotates within a housing, engaging with pins or rollers to transmit torque. This design allows for high torque transmission with minimal backlash, making them ideal for applications requiring precise positioning and smooth operation. The global market for high precision cycloidal gears is driven by the increasing demand for automation and robotics in industries such as manufacturing, automotive, and aerospace. As industries continue to seek more efficient and reliable motion control solutions, the demand for these gears is expected to grow. The market is also influenced by advancements in gear manufacturing technologies, which have improved the performance and durability of cycloidal gears. Additionally, the growing trend towards miniaturization in various applications has further boosted the demand for compact and high-performance gear solutions like cycloidal gears. Overall, the high precision cycloidal gear market is poised for significant growth as industries continue to prioritize efficiency and precision in their operations.

Single Stage Cycloidal Gearing, Double-Stage Cycloidal Gearing in the High Precision Cycloidal Gear - Global Market:

Single-stage cycloidal gearing and double-stage cycloidal gearing are two configurations of high precision cycloidal gears, each offering distinct advantages and applications. Single-stage cycloidal gearing involves a single cycloidal disc and is typically used in applications where moderate speed reduction and high torque transmission are required. This configuration is known for its simplicity and compact design, making it suitable for applications with limited space. Single-stage cycloidal gears are often used in robotics, where precise motion control is essential, and in machine tools, where they provide smooth and accurate positioning. On the other hand, double-stage cycloidal gearing involves two cycloidal discs, providing a higher reduction ratio and increased torque capacity. This configuration is ideal for applications requiring significant speed reduction and high torque, such as heavy machinery and industrial equipment. Double-stage cycloidal gears offer enhanced performance and durability, making them suitable for demanding applications in industries like construction and mining. Both single-stage and double-stage cycloidal gears benefit from the inherent advantages of cycloidal design, including low backlash, high efficiency, and smooth operation. These features make them highly desirable in applications where precision and reliability are critical. As the demand for automation and advanced machinery continues to rise, the market for both single-stage and double-stage cycloidal gearing is expected to expand, driven by the need for efficient and reliable motion control solutions.

Machine Tools, Industrial Robots, Others (Automotive Systems, etc) in the High Precision Cycloidal Gear - Global Market:

High precision cycloidal gears find extensive usage in various sectors, including machine tools, industrial robots, and other applications such as automotive systems. In the realm of machine tools, these gears are integral to ensuring precise and smooth operation. Machine tools require accurate positioning and consistent performance, which cycloidal gears provide through their unique design that minimizes backlash and enhances torque transmission. This precision is crucial in applications like CNC machines, where even the slightest error can lead to significant defects in the final product. In industrial robots, high precision cycloidal gears are essential for achieving the precise and repeatable movements required in automated processes. These gears enable robots to perform complex tasks with high accuracy, making them indispensable in manufacturing environments where efficiency and precision are paramount. The low backlash and high torque capacity of cycloidal gears ensure that robots can handle various tasks, from assembly to welding, with ease and reliability. Beyond machine tools and industrial robots, cycloidal gears are also used in automotive systems and other applications where precision and efficiency are critical. In automotive systems, these gears contribute to the smooth operation of components such as steering systems and transmission systems, enhancing overall vehicle performance. The versatility and reliability of high precision cycloidal gears make them a preferred choice in various industries seeking to optimize their operations and improve product quality. As industries continue to embrace automation and advanced technologies, the demand for high precision cycloidal gears is expected to grow, driven by the need for efficient and reliable motion control solutions.

High Precision Cycloidal Gear - Global Market Outlook:

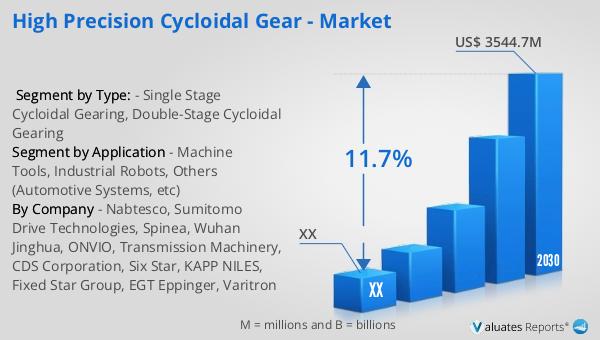

The global market for high precision cycloidal gears was valued at approximately US$ 1,632 million in 2023, with projections indicating a significant increase to US$ 3,544.7 million by 2030. This growth represents a compound annual growth rate (CAGR) of 11.7% during the forecast period from 2024 to 2030. This upward trend is indicative of the increasing demand for high precision cycloidal gears across various industries, driven by the need for efficient and reliable motion control solutions. In the construction machinery sector, for instance, sales in Europe saw a 24% increase in 2021, highlighting the growing demand for advanced machinery. By 2022, construction machinery revenue in Europe reached approximately US$ 22 billion, while the US market recorded sales of about US$ 36 billion. These figures underscore the expanding market for high precision cycloidal gears, as industries continue to prioritize automation and precision in their operations. The robust growth in the construction machinery sector is a testament to the increasing adoption of advanced technologies and the critical role of high precision cycloidal gears in enhancing machinery performance and efficiency. As industries continue to evolve and embrace new technologies, the demand for high precision cycloidal gears is expected to remain strong, driven by the need for reliable and efficient motion control solutions.

| Report Metric | Details |

| Report Name | High Precision Cycloidal Gear - Market |

| Forecasted market size in 2030 | US$ 3544.7 million |

| CAGR | 11.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Nabtesco, Sumitomo Drive Technologies, Spinea, Wuhan Jinghua, ONVIO, Transmission Machinery, CDS Corporation, Six Star, KAPP NILES, Fixed Star Group, EGT Eppinger, Varitron |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |