What is Chemical Industry Distributed Control System - Global Market?

The Chemical Industry Distributed Control System (DCS) - Global Market is a crucial segment within the broader industrial automation landscape. Distributed Control Systems are integral to the chemical industry as they provide a centralized framework for managing and controlling complex processes. These systems are designed to enhance operational efficiency, safety, and reliability by automating various processes and providing real-time data analysis. The global market for DCS in the chemical industry is driven by the increasing demand for automation and the need to improve production efficiency and safety standards. As industries strive to meet stringent regulatory requirements and optimize their operations, the adoption of DCS is becoming more widespread. The market is characterized by technological advancements, such as the integration of IoT and AI, which are further enhancing the capabilities of these systems. The growth of the market is also fueled by the expansion of the chemical industry in emerging economies, where there is a significant push towards modernization and automation. Overall, the Chemical Industry Distributed Control System - Global Market is poised for steady growth as industries continue to prioritize efficiency and safety in their operations.

Hardware, Software, Services in the Chemical Industry Distributed Control System - Global Market:

In the realm of the Chemical Industry Distributed Control System - Global Market, hardware, software, and services play pivotal roles in shaping the landscape. Hardware components in DCS include controllers, input/output modules, and communication devices that form the backbone of the system. These components are responsible for executing control algorithms and facilitating communication between various parts of the system. The demand for robust and reliable hardware is high, as it directly impacts the performance and reliability of the entire system. On the software front, DCS solutions offer sophisticated platforms that enable process control, data acquisition, and analysis. Software solutions are designed to be user-friendly, providing operators with intuitive interfaces to monitor and control processes efficiently. Advanced software capabilities, such as predictive analytics and machine learning, are being integrated to enhance decision-making and optimize operations. Services associated with DCS encompass a wide range of offerings, including system design, installation, maintenance, and support. Service providers play a crucial role in ensuring that DCS systems are tailored to meet the specific needs of chemical plants, providing ongoing support to maximize system uptime and performance. The integration of hardware, software, and services is essential for the successful deployment and operation of DCS in the chemical industry, enabling companies to achieve their operational goals while maintaining high safety and efficiency standards.

Small Size, Medium Size, Large Size in the Chemical Industry Distributed Control System - Global Market:

The usage of Chemical Industry Distributed Control System - Global Market varies significantly across small, medium, and large-sized enterprises, each with its unique set of requirements and challenges. In small-sized chemical plants, the adoption of DCS is often driven by the need to streamline operations and reduce manual intervention. These plants benefit from the scalability and flexibility of DCS, which allows them to automate key processes without incurring excessive costs. The focus is typically on enhancing process efficiency and ensuring compliance with safety regulations. Medium-sized enterprises, on the other hand, leverage DCS to manage more complex operations and integrate various processes across different units. The ability to centralize control and monitor operations in real-time is a significant advantage for these companies, enabling them to optimize resource utilization and improve product quality. For large-sized chemical plants, DCS is indispensable due to the sheer scale and complexity of their operations. These enterprises require advanced DCS solutions that can handle vast amounts of data and provide comprehensive insights into plant performance. The emphasis is on achieving operational excellence, minimizing downtime, and ensuring the highest levels of safety and compliance. Across all sizes, the adoption of DCS is driven by the need to enhance efficiency, reduce costs, and maintain competitiveness in a rapidly evolving market.

Chemical Industry Distributed Control System - Global Market Outlook:

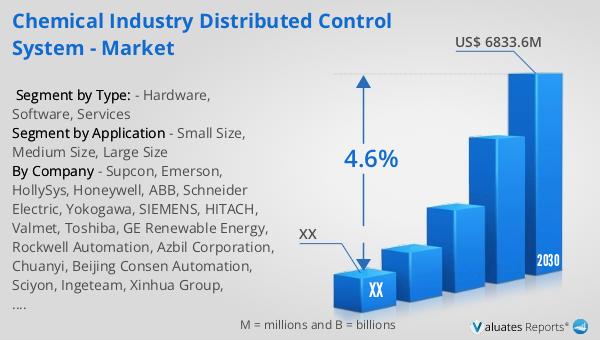

The outlook for the Chemical Industry Distributed Control System - Global Market indicates a promising trajectory. In 2023, the market was valued at approximately US$ 4981.3 million, and it is projected to grow to a revised size of US$ 6833.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2024 to 2030. This growth is largely attributed to the increasing demand for automation and the need to improve operational efficiency and safety in the chemical industry. A significant driver of this market is the server segment, which plays a crucial role in supporting the infrastructure of DCS. According to IDC, the global server market was estimated at US$110 billion in 2022, with the top five players holding a substantial share of about 45 percent. This indicates a strong foundation for the growth of DCS, as robust server infrastructure is essential for the seamless operation of these systems. As the chemical industry continues to evolve and embrace digital transformation, the demand for advanced DCS solutions is expected to rise, further propelling the market forward.

| Report Metric | Details |

| Report Name | Chemical Industry Distributed Control System - Market |

| Forecasted market size in 2030 | US$ 6833.6 million |

| CAGR | 4.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Supcon, Emerson, HollySys, Honeywell, ABB, Schneider Electric, Yokogawa, SIEMENS, HITACH, Valmet, Toshiba, GE Renewable Energy, Rockwell Automation, Azbil Corporation, Chuanyi, Beijing Consen Automation, Sciyon, Ingeteam, Xinhua Group, Shanghai Automation, Luneng, Mitsubishi Electric Corporation, ANDRITZ, Nanjing Delto Technology, ZAT Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |