What is Vibration Monitoring Devices - Global Market?

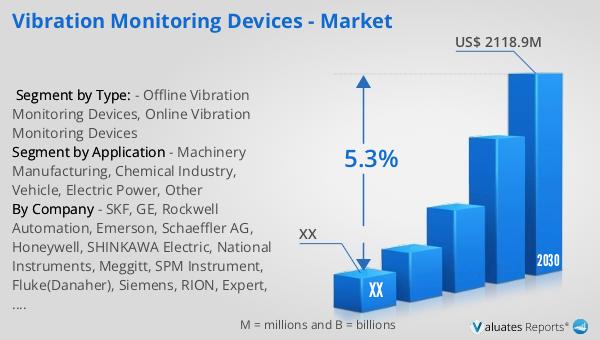

The global market for vibration monitoring devices is a dynamic and rapidly evolving sector, driven by the increasing need for predictive maintenance and the desire to minimize downtime in various industries. These devices are essential tools used to monitor the condition of machinery and equipment by measuring vibrations, which can indicate potential issues such as imbalance, misalignment, or wear and tear. In 2023, the market was valued at approximately US$ 1465 million, and it is projected to grow to around US$ 2118.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.3% from 2024 to 2030. North America leads the market, holding about 40% of the market share, followed by Europe with approximately 29%. The top three companies in this sector account for about 28% of the market share, highlighting a competitive landscape where innovation and technological advancements are key drivers. As industries continue to prioritize efficiency and reliability, the demand for vibration monitoring devices is expected to rise, making this market a crucial component of modern industrial operations.

Offline Vibration Monitoring Devices, Online Vibration Monitoring Devices in the Vibration Monitoring Devices - Global Market:

Vibration monitoring devices are categorized into two main types: offline and online systems, each serving distinct purposes within the global market. Offline vibration monitoring devices are typically used for periodic checks and maintenance schedules. These devices are portable and are brought to the site to measure the vibration levels of machinery at specific intervals. They are ideal for industries where continuous monitoring is not feasible or necessary, allowing maintenance teams to gather data and analyze it to predict potential failures. This approach is cost-effective and suitable for smaller operations or less critical machinery where real-time data is not crucial. On the other hand, online vibration monitoring devices provide continuous, real-time data on the condition of machinery. These systems are permanently installed on equipment and are connected to a central monitoring system. They are essential for critical machinery where any downtime could lead to significant financial losses or safety hazards. Online systems offer the advantage of immediate alerts and insights, enabling quick responses to any detected anomalies. This continuous monitoring is particularly beneficial in industries such as oil and gas, power generation, and manufacturing, where equipment reliability is paramount. The choice between offline and online systems depends on several factors, including the criticality of the machinery, budget constraints, and the specific needs of the operation. As technology advances, the integration of IoT and AI in vibration monitoring devices is enhancing their capabilities, providing more accurate diagnostics and predictive maintenance solutions. This evolution is driving the global market forward, as industries seek to optimize their operations and reduce maintenance costs.

Machinery Manufacturing, Chemical Industry, Vehicle, Electric Power, Other in the Vibration Monitoring Devices - Global Market:

Vibration monitoring devices play a crucial role in various industries, including machinery manufacturing, the chemical industry, vehicles, electric power, and others. In machinery manufacturing, these devices are used to ensure the smooth operation of equipment by detecting any irregular vibrations that could indicate potential issues. By identifying problems early, manufacturers can prevent costly breakdowns and extend the lifespan of their machinery. In the chemical industry, where precision and safety are paramount, vibration monitoring devices help maintain the integrity of equipment such as pumps, compressors, and mixers. These devices ensure that machinery operates within safe parameters, reducing the risk of leaks or failures that could lead to hazardous situations. In the automotive sector, vibration monitoring is used to enhance vehicle performance and safety. By analyzing the vibrations of engines and other components, manufacturers can identify areas for improvement and ensure that vehicles meet stringent quality standards. In the electric power industry, vibration monitoring devices are used to maintain the reliability of generators, turbines, and other critical equipment. By continuously monitoring vibrations, power companies can detect potential issues before they lead to outages or equipment damage. Other industries, such as mining, construction, and aerospace, also benefit from vibration monitoring devices, as they provide valuable insights into the condition of machinery and help optimize maintenance schedules. Overall, the use of vibration monitoring devices across these sectors highlights their importance in ensuring operational efficiency, safety, and cost-effectiveness.

Vibration Monitoring Devices - Global Market Outlook:

The global market for vibration monitoring devices was valued at approximately US$ 1465 million in 2023, with expectations to grow to around US$ 2118.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.3% from 2024 to 2030. North America holds the largest share of this market, accounting for about 40%, followed by Europe with approximately 29%. The top three companies in this sector collectively occupy about 28% of the market share, indicating a competitive landscape where innovation and technological advancements are key drivers. As industries continue to prioritize efficiency and reliability, the demand for vibration monitoring devices is expected to rise, making this market a crucial component of modern industrial operations. The growth of this market is driven by the increasing need for predictive maintenance and the desire to minimize downtime in various industries. These devices are essential tools used to monitor the condition of machinery and equipment by measuring vibrations, which can indicate potential issues such as imbalance, misalignment, or wear and tear. As industries continue to prioritize efficiency and reliability, the demand for vibration monitoring devices is expected to rise, making this market a crucial component of modern industrial operations.

| Report Metric | Details |

| Report Name | Vibration Monitoring Devices - Market |

| Forecasted market size in 2030 | US$ 2118.9 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | SKF, GE, Rockwell Automation, Emerson, Schaeffler AG, Honeywell, SHINKAWA Electric, National Instruments, Meggitt, SPM Instrument, Fluke(Danaher), Siemens, RION, Expert, Instantel, Bruel & Kjaer, Donghua |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |