What is Polymer Preparation System - Global Market?

Polymer Preparation Systems are essential components in various industries, designed to efficiently prepare and manage polymers for different applications. These systems are crucial for ensuring that polymers are mixed, activated, and delivered in the right concentrations and forms for their intended use. The global market for Polymer Preparation Systems is driven by the increasing demand for efficient water treatment solutions, advancements in polymer technology, and the growing need for automation in industrial processes. These systems are used in a variety of sectors, including water treatment, petrochemicals, and manufacturing, where they help in optimizing the use of polymers, reducing waste, and improving process efficiency. The market is characterized by a wide range of products, including both powder and liquid polymer preparation systems, each designed to meet specific industry needs. As industries continue to seek more sustainable and cost-effective solutions, the demand for advanced polymer preparation systems is expected to grow, driving innovation and development in this field. The systems are not only about mixing polymers but also about ensuring the right chemical reactions occur to achieve the desired properties in the final product. This makes them indispensable in industries where precision and efficiency are paramount.

Powder or Granular Polymer Preparation System, Liquid Polymer Preparation Units System in the Polymer Preparation System - Global Market:

Powder or Granular Polymer Preparation Systems and Liquid Polymer Preparation Units are two primary types of systems used in the global market for polymer preparation. Powder or Granular Polymer Preparation Systems are designed to handle dry polymers, which are often preferred for their longer shelf life and ease of storage. These systems typically involve the use of feeders, mixers, and dissolvers to ensure that the polymer is properly hydrated and activated before use. The process begins with the accurate dosing of the polymer powder, which is then mixed with water to form a solution. This solution is then allowed to mature, ensuring that the polymer chains are fully activated and ready for application. These systems are widely used in industries where large volumes of polymer solutions are required, such as in wastewater treatment and paper manufacturing. On the other hand, Liquid Polymer Preparation Units are designed to handle liquid polymers, which are often used for their ease of handling and rapid activation. These systems typically involve the use of pumps, mixers, and dosing units to ensure that the polymer is delivered in the correct concentration and form. Liquid polymers are often used in applications where quick response times are critical, such as in emergency spill response or rapid water treatment scenarios. Both types of systems are designed to optimize the use of polymers, ensuring that they are used efficiently and effectively in their respective applications. The choice between powder and liquid systems often depends on the specific requirements of the application, including factors such as the volume of polymer required, the desired activation time, and the available storage space. In recent years, there has been a growing trend towards the use of automated polymer preparation systems, which offer improved accuracy, efficiency, and ease of use. These systems often incorporate advanced technologies such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to provide precise control over the polymer preparation process. This not only helps to reduce waste and improve process efficiency but also ensures that the final product meets the required quality standards. As industries continue to seek more sustainable and cost-effective solutions, the demand for advanced polymer preparation systems is expected to grow, driving innovation and development in this field.

Drinking Water Treatment, Wastewater Treatment, Petrochemical, Others in the Polymer Preparation System - Global Market:

Polymer Preparation Systems play a crucial role in various applications, including drinking water treatment, wastewater treatment, petrochemical processes, and other industrial uses. In drinking water treatment, these systems are used to prepare coagulants and flocculants, which are essential for removing impurities and contaminants from water. The polymers help in aggregating suspended particles, making it easier to filter them out and produce clean, safe drinking water. This process is vital for ensuring public health and meeting regulatory standards for water quality. In wastewater treatment, Polymer Preparation Systems are used to enhance the efficiency of sludge dewatering and solid-liquid separation processes. The polymers help in binding the solid particles in the wastewater, allowing them to be more easily separated from the liquid. This not only improves the efficiency of the treatment process but also reduces the volume of sludge that needs to be disposed of, resulting in cost savings and environmental benefits. In the petrochemical industry, Polymer Preparation Systems are used in various processes, including the production of synthetic rubber, plastics, and other polymer-based products. These systems help in ensuring that the polymers are prepared and delivered in the right concentrations and forms, optimizing the production process and improving the quality of the final product. The use of polymers in the petrochemical industry is critical for producing a wide range of products that are used in everyday life, from packaging materials to automotive components. In addition to these applications, Polymer Preparation Systems are also used in other industries, such as paper manufacturing, mining, and textiles. In paper manufacturing, polymers are used as retention aids and drainage aids, helping to improve the quality and efficiency of the paper production process. In mining, polymers are used in mineral processing and tailings management, helping to improve the recovery of valuable minerals and reduce the environmental impact of mining operations. In textiles, polymers are used in various finishing processes, helping to improve the durability and performance of textile products. Overall, the use of Polymer Preparation Systems in these various applications highlights their importance in modern industrial processes, where efficiency, sustainability, and quality are paramount.

Polymer Preparation System - Global Market Outlook:

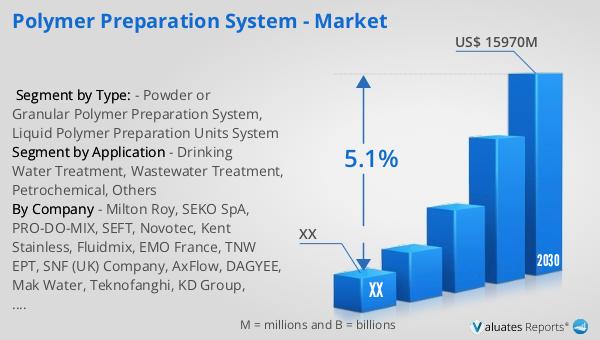

The global market for Polymer Preparation Systems was valued at approximately USD 10,470 million in 2023. It is projected to grow to a revised size of USD 15,970 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.1% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and effective polymer preparation solutions across various industries. In North America, the market for Polymer Preparation Systems was valued at a significant amount in 2023 and is expected to continue its growth trajectory through to 2030. The CAGR for this region during the forecast period is anticipated to be robust, reflecting the strong demand for polymer preparation systems in industries such as water treatment, petrochemicals, and manufacturing. The growth in the North American market is driven by factors such as technological advancements, increasing regulatory requirements for water and wastewater treatment, and the growing need for sustainable and cost-effective solutions. As industries continue to evolve and seek more efficient processes, the demand for advanced polymer preparation systems is expected to rise, contributing to the overall growth of the global market. This market outlook underscores the importance of polymer preparation systems in modern industrial processes and highlights the opportunities for innovation and development in this field.

| Report Metric | Details |

| Report Name | Polymer Preparation System - Market |

| Forecasted market size in 2030 | US$ 15970 million |

| CAGR | 5.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Milton Roy, SEKO SpA, PRO-DO-MIX, SEFT, Novotec, Kent Stainless, Fluidmix, EMO France, TNW EPT, SNF (UK) Company, AxFlow, DAGYEE, Mak Water, Teknofanghi, KD Group, Chemical Support Systems, Baioni, Sodimate, BOEEP, Alltech, JNE Environmental, Hyxo, Mak Process, Polymore AB, Biotec, Kozegho |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |