What is Power Plant Distributed Control System - Global Market?

The Power Plant Distributed Control System (DCS) is a sophisticated technology used globally to manage and control power plants efficiently. It integrates various control systems within a power plant, allowing operators to monitor and control processes from a central location. This system is crucial for ensuring the smooth operation of power plants, enhancing their efficiency, and reducing downtime. The global market for Power Plant DCS is expanding due to the increasing demand for reliable and efficient power generation solutions. As power plants become more complex, the need for advanced control systems like DCS becomes more critical. These systems help in optimizing the performance of power plants, reducing operational costs, and improving safety standards. The market is driven by the growing adoption of renewable energy sources, which require sophisticated control systems to manage their variable output. Additionally, the push for carbon neutrality and environmental sustainability is propelling the demand for advanced DCS solutions in power plants worldwide.

Hardware, Software, Services in the Power Plant Distributed Control System - Global Market:

The Power Plant Distributed Control System market is segmented into hardware, software, and services, each playing a vital role in the overall functionality and efficiency of power plants. Hardware components in a DCS include controllers, input/output modules, and communication networks. These components are essential for the physical operation of the control system, allowing for real-time data acquisition and processing. Controllers are the brain of the DCS, executing control algorithms and ensuring the plant operates within set parameters. Input/output modules facilitate the exchange of data between the plant's physical processes and the control system, enabling precise monitoring and control. Communication networks ensure seamless data transfer across the system, supporting the integration of various plant components. On the software side, DCS solutions offer advanced functionalities such as process automation, data analytics, and visualization tools. These software applications enable operators to monitor plant performance, identify inefficiencies, and implement corrective actions promptly. Process automation software helps in optimizing plant operations by automating routine tasks, reducing human intervention, and minimizing errors. Data analytics tools provide insights into plant performance, helping operators make informed decisions to enhance efficiency and productivity. Visualization tools offer intuitive interfaces for operators to monitor plant processes, ensuring quick response to any anomalies. Services in the DCS market include installation, maintenance, and support services. These services are crucial for ensuring the smooth operation of the DCS, minimizing downtime, and extending the lifespan of the system. Installation services involve setting up the DCS components and integrating them with existing plant infrastructure. Maintenance services include regular inspections, troubleshooting, and repairs to keep the system running optimally. Support services provide technical assistance and training for plant operators, ensuring they can effectively use the DCS to manage plant operations. The combination of hardware, software, and services in the Power Plant DCS market ensures that power plants can operate efficiently, safely, and sustainably. As the demand for reliable and efficient power generation solutions continues to grow, the market for Power Plant DCS is expected to expand, driven by advancements in technology and the increasing adoption of renewable energy sources.

Small Size, Medium Size, Large Size in the Power Plant Distributed Control System - Global Market:

Power Plant Distributed Control Systems are utilized across various sizes of power plants, each with unique requirements and challenges. In small-sized power plants, DCS solutions are essential for managing limited resources efficiently. These plants often operate with constrained budgets and personnel, making automation and control systems crucial for optimizing operations. DCS in small plants helps in automating routine tasks, reducing the need for manual intervention, and minimizing operational costs. The system's ability to integrate various plant components ensures seamless operation, even with limited resources. In medium-sized power plants, DCS solutions play a critical role in managing more complex operations. These plants require advanced control systems to handle increased output and ensure reliability. DCS in medium-sized plants provides comprehensive monitoring and control capabilities, enabling operators to manage plant processes effectively. The system's scalability allows for easy integration of additional components as the plant expands, ensuring continued efficiency and performance. In large-sized power plants, DCS solutions are indispensable for managing extensive operations and ensuring safety. These plants operate with significant output and require sophisticated control systems to maintain stability and efficiency. DCS in large plants offers advanced functionalities such as predictive maintenance, real-time analytics, and remote monitoring. These features enable operators to anticipate potential issues, optimize performance, and ensure the plant operates within regulatory standards. The system's ability to handle vast amounts of data and integrate with other plant systems ensures seamless operation and enhanced safety. Across all sizes, Power Plant DCS solutions are crucial for optimizing operations, reducing costs, and ensuring safety and reliability. As power plants continue to evolve and adopt new technologies, the demand for advanced DCS solutions is expected to grow, driven by the need for efficient and sustainable power generation.

Power Plant Distributed Control System - Global Market Outlook:

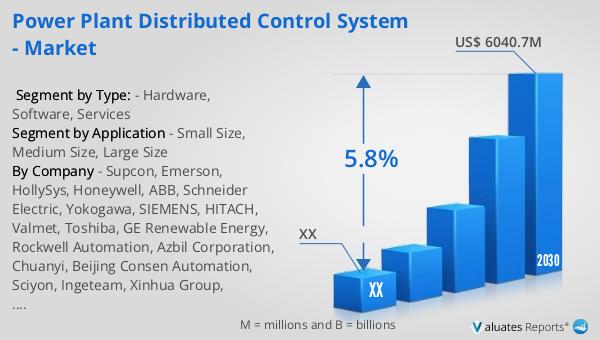

The global market for Power Plant Distributed Control Systems was valued at approximately $4,055.5 million in 2023 and is projected to reach around $6,040.7 million by 2030, growing at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth is largely attributed to the rapid development of the wind power and photovoltaic industries, as well as the increasing awareness of environmental protection across various countries. As nations strive to achieve carbon neutrality, the energy storage industry has emerged as a key technology in advancing these goals. The integration of DCS solutions in power plants is essential for managing the variable output of renewable energy sources, ensuring stability and efficiency. The growing emphasis on environmental sustainability and the transition towards cleaner energy sources are driving the demand for advanced DCS solutions in power plants worldwide. As the market continues to expand, the focus will be on developing innovative technologies that enhance the efficiency and reliability of power plant operations, supporting the global shift towards a more sustainable energy future.

| Report Metric | Details |

| Report Name | Power Plant Distributed Control System - Market |

| Forecasted market size in 2030 | US$ 6040.7 million |

| CAGR | 5.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Supcon, Emerson, HollySys, Honeywell, ABB, Schneider Electric, Yokogawa, SIEMENS, HITACH, Valmet, Toshiba, GE Renewable Energy, Rockwell Automation, Azbil Corporation, Chuanyi, Beijing Consen Automation, Sciyon, Ingeteam, Xinhua Group, Shanghai Automation, Luneng, Mitsubishi Electric Corporation, ANDRITZ, Nanjing Delto Technology, ZAT Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |