What is Industry Carbon Brushes - Global Market?

Industry carbon brushes are essential components in various electrical devices and machinery, playing a crucial role in conducting electrical current between stationary wires and rotating parts. These brushes are typically made from carbon or graphite, which are chosen for their excellent conductivity and ability to withstand high temperatures. The global market for industry carbon brushes is driven by their widespread application in numerous sectors, including automotive, industrial machinery, and consumer electronics. As industries continue to expand and modernize, the demand for efficient and reliable electrical components like carbon brushes is expected to grow. These brushes are vital in ensuring the smooth operation of motors and generators, reducing wear and tear, and enhancing the longevity of the equipment. The market is characterized by a diverse range of products tailored to specific industrial needs, with ongoing innovations aimed at improving performance and durability. Manufacturers are focusing on developing brushes that offer better efficiency and lower maintenance costs, catering to the evolving demands of various industries. The global market for industry carbon brushes is poised for steady growth, driven by technological advancements and the increasing adoption of automation across different sectors.

AC Motors, DC Motors in the Industry Carbon Brushes - Global Market:

AC motors and DC motors are integral to the industry carbon brushes market, each serving distinct functions and applications. AC motors, or alternating current motors, are widely used in various industrial and commercial applications due to their efficiency and reliability. They operate on alternating current and are known for their ability to handle high power loads, making them suitable for heavy machinery and equipment. AC motors are commonly found in applications such as pumps, fans, compressors, and conveyor systems. The use of carbon brushes in AC motors is crucial for maintaining electrical contact and ensuring smooth operation. These brushes help in transferring current to the rotating parts of the motor, minimizing friction and wear. On the other hand, DC motors, or direct current motors, are known for their precision and control. They operate on direct current and are often used in applications where speed control and torque are critical. DC motors are commonly found in electric vehicles, robotics, and small appliances. Carbon brushes in DC motors play a vital role in maintaining electrical contact and ensuring efficient operation. They help in transferring current to the commutator, which in turn powers the motor. The global market for industry carbon brushes is influenced by the demand for both AC and DC motors, with manufacturers focusing on developing brushes that cater to the specific needs of each type of motor. The ongoing advancements in motor technology, coupled with the increasing adoption of automation and electric vehicles, are expected to drive the demand for carbon brushes in the coming years. As industries continue to evolve, the need for efficient and reliable electrical components like carbon brushes will remain a key factor in the growth of the global market.

Steel-Cement-Paper Mills, Textile and Plastic Industry, Power Stations, Others in the Industry Carbon Brushes - Global Market:

Industry carbon brushes are widely used in various sectors, including steel, cement, and paper mills, as well as the textile and plastic industries, power stations, and other applications. In steel mills, carbon brushes are essential for the operation of electric arc furnaces and rolling mills, where they help in conducting electrical current and ensuring smooth operation. The high temperatures and harsh conditions in steel mills require brushes that can withstand extreme environments and provide reliable performance. In cement mills, carbon brushes are used in the operation of rotary kilns and grinding mills, where they help in maintaining electrical contact and ensuring efficient operation. The abrasive nature of cement production requires brushes that are durable and capable of withstanding wear and tear. In paper mills, carbon brushes are used in the operation of paper machines and other equipment, where they help in transferring current and ensuring smooth operation. The high-speed nature of paper production requires brushes that can provide reliable performance and minimize downtime. In the textile and plastic industries, carbon brushes are used in various machinery and equipment, where they help in maintaining electrical contact and ensuring efficient operation. The diverse range of applications in these industries requires brushes that are tailored to specific needs and capable of providing reliable performance. In power stations, carbon brushes are used in generators and other equipment, where they help in conducting electrical current and ensuring smooth operation. The critical nature of power generation requires brushes that are reliable and capable of withstanding high temperatures and harsh conditions. The global market for industry carbon brushes is driven by the demand for efficient and reliable electrical components in these sectors, with manufacturers focusing on developing brushes that cater to the specific needs of each industry. The ongoing advancements in technology and the increasing adoption of automation are expected to drive the demand for carbon brushes in the coming years.

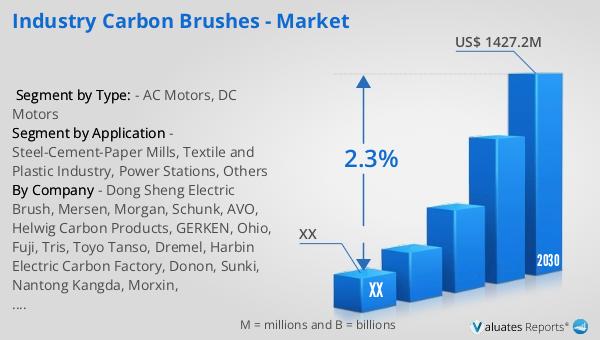

Industry Carbon Brushes - Global Market Outlook:

The global market for industry carbon brushes was valued at approximately $1,214.7 million in 2023, with projections indicating a growth to around $1,427.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.3% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for carbon brushes across various industries, driven by technological advancements and the need for efficient and reliable electrical components. In the construction machinery sector, for instance, there has been a notable increase in sales, particularly in Europe, where sales rose by 24% in 2021. By 2022, the revenue from construction machinery in Europe reached approximately $22 billion, while the U.S. market saw sales of about $36 billion in construction machinery. These figures highlight the growing demand for machinery and equipment that rely on components like carbon brushes for optimal performance. As industries continue to expand and modernize, the need for high-quality carbon brushes is expected to rise, contributing to the overall growth of the global market. The focus on developing brushes that offer better efficiency and lower maintenance costs will be crucial in meeting the evolving demands of various sectors.

| Report Metric | Details |

| Report Name | Industry Carbon Brushes - Market |

| Forecasted market size in 2030 | US$ 1427.2 million |

| CAGR | 2.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Dong Sheng Electric Brush, Mersen, Morgan, Schunk, AVO, Helwig Carbon Products, GERKEN, Ohio, Fuji, Tris, Toyo Tanso, Dremel, Harbin Electric Carbon Factory, Donon, Sunki, Nantong Kangda, Morxin, Schmidthammmer, Fuyung Carbon |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |