What is 4 Axis Dental Milling Machine - Global Market?

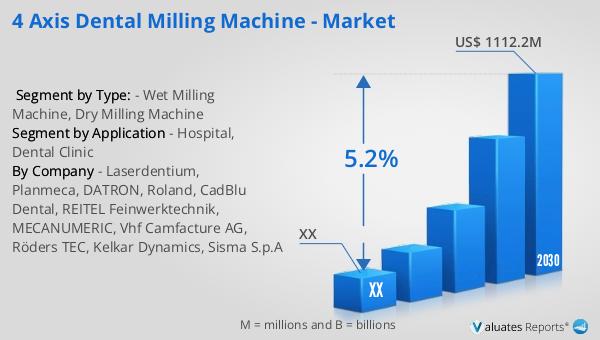

The 4 Axis Dental Milling Machine is a sophisticated piece of equipment used in the dental industry to create precise dental restorations such as crowns, bridges, and dentures. This machine operates on four axes, allowing it to mill complex shapes and contours with high accuracy. The global market for these machines is expanding due to the increasing demand for dental restorations and advancements in dental technology. As of 2023, the market was valued at approximately US$ 774.5 million and is projected to grow to US$ 1112.2 million by 2030, with a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030. This growth is driven by the rising prevalence of dental disorders, an aging population, and the growing adoption of digital dentistry. The 4 Axis Dental Milling Machine offers dental professionals the ability to produce high-quality restorations in-house, reducing the need for outsourcing and improving turnaround times. This capability is particularly beneficial in enhancing patient satisfaction and streamlining dental practice operations. As the market continues to evolve, innovations in milling technology and materials are expected to further enhance the capabilities and efficiency of these machines.

Wet Milling Machine, Dry Milling Machine in the 4 Axis Dental Milling Machine - Global Market:

In the realm of dental milling, two primary types of machines are prevalent: wet milling machines and dry milling machines. Both types are integral to the 4 Axis Dental Milling Machine market, each offering distinct advantages and applications. Wet milling machines utilize a liquid coolant to facilitate the milling process. This coolant helps to reduce heat and friction, which can be beneficial when working with materials that are sensitive to high temperatures, such as ceramics. The use of a coolant also helps to extend the life of the milling tools by reducing wear and tear. Wet milling is particularly advantageous for producing restorations with a high degree of precision and smooth surface finishes. This method is often preferred for creating intricate dental prosthetics that require a high level of detail and accuracy. On the other hand, dry milling machines operate without the use of liquid coolants. This method is typically used for milling materials that do not require cooling, such as zirconia. Dry milling is often faster and more cost-effective than wet milling, as it eliminates the need for coolant management and disposal. Additionally, dry milling machines are generally easier to maintain and clean, making them a popular choice for dental labs and clinics that prioritize efficiency and simplicity. The choice between wet and dry milling largely depends on the specific requirements of the dental restoration being produced, as well as the materials being used. In the global market, both wet and dry milling machines are seeing increased adoption due to their respective benefits. The versatility of 4 Axis Dental Milling Machines allows dental professionals to choose the most appropriate method for their needs, whether it be the precision and detail of wet milling or the speed and cost-effectiveness of dry milling. As the dental industry continues to advance, the demand for both wet and dry milling machines is expected to grow, driven by the need for high-quality, efficient dental restoration solutions. The ongoing development of new materials and milling technologies will likely further enhance the capabilities of these machines, providing dental professionals with even more options for delivering optimal patient care.

Hospital, Dental Clinic in the 4 Axis Dental Milling Machine - Global Market:

The usage of 4 Axis Dental Milling Machines in hospitals and dental clinics is becoming increasingly prevalent as these institutions strive to enhance their dental care services. In hospitals, these machines are utilized to support a wide range of dental procedures, from routine check-ups to complex restorative treatments. The ability to produce precise dental restorations in-house allows hospitals to offer comprehensive dental care services without the need for outsourcing, which can be time-consuming and costly. This capability is particularly beneficial in hospital settings where timely and efficient patient care is paramount. By integrating 4 Axis Dental Milling Machines into their operations, hospitals can improve patient outcomes by providing high-quality dental restorations with reduced waiting times. In dental clinics, the adoption of 4 Axis Dental Milling Machines is driven by the need to enhance patient satisfaction and streamline practice operations. These machines enable dental clinics to produce custom dental restorations on-site, allowing for faster turnaround times and more personalized care. Patients benefit from the convenience of receiving their dental prosthetics in a single visit, reducing the need for multiple appointments and improving overall treatment experience. The precision and accuracy of 4 Axis Dental Milling Machines also contribute to better-fitting restorations, which can enhance patient comfort and satisfaction. Additionally, the ability to produce restorations in-house allows dental clinics to maintain greater control over the quality of their products, ensuring that they meet the highest standards of care. As the demand for digital dentistry continues to grow, the integration of 4 Axis Dental Milling Machines in hospitals and dental clinics is expected to increase. These machines offer a valuable solution for institutions looking to improve their dental care services and provide patients with high-quality, efficient treatment options. The ongoing advancements in milling technology and materials will likely further enhance the capabilities of these machines, enabling hospitals and dental clinics to deliver even better patient care in the future.

4 Axis Dental Milling Machine - Global Market Outlook:

The global market for 4 Axis Dental Milling Machines was valued at approximately US$ 774.5 million in 2023, with projections indicating a growth to US$ 1112.2 million by 2030. This represents a compound annual growth rate (CAGR) of 5.2% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for advanced dental restoration solutions and the adoption of digital dentistry practices worldwide. The broader medical devices market, estimated at US$ 603 billion in 2023, is also expected to grow at a CAGR of 5% over the next six years. This parallel growth highlights the expanding role of technology in healthcare and the increasing emphasis on precision and efficiency in medical treatments. The 4 Axis Dental Milling Machine market is poised to benefit from these trends, as dental professionals seek to enhance their capabilities and improve patient outcomes through the use of advanced milling technology. As the market continues to evolve, innovations in materials and milling techniques are expected to further drive growth, providing dental professionals with even more tools to deliver high-quality care. The integration of these machines into dental practices and hospitals is likely to become increasingly common, as institutions recognize the value of in-house production of dental restorations in terms of cost savings, efficiency, and patient satisfaction.

| Report Metric | Details |

| Report Name | 4 Axis Dental Milling Machine - Market |

| Forecasted market size in 2030 | US$ 1112.2 million |

| CAGR | 5.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Laserdentium, Planmeca, DATRON, Roland, CadBlu Dental, REITEL Feinwerktechnik, MECANUMERIC, Vhf Camfacture AG, Röders TEC, Kelkar Dynamics, Sisma S.p.A |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |