What is Commercial Vehicle Aluminum Casting - Global Market?

Commercial Vehicle Aluminum Casting refers to the process of creating aluminum components for vehicles like trucks and special vehicles. This market is a significant part of the automotive industry, focusing on producing lightweight, durable, and efficient parts. Aluminum casting is favored in the commercial vehicle sector due to its ability to reduce vehicle weight, which in turn enhances fuel efficiency and reduces emissions. The global market for commercial vehicle aluminum casting is driven by the increasing demand for fuel-efficient vehicles and stringent environmental regulations. Manufacturers are investing in advanced casting technologies to improve the quality and performance of aluminum parts. The market is also influenced by the growth of the automotive industry, particularly in regions like Asia, Europe, and North America, where vehicle production is concentrated. As the demand for commercial vehicles continues to rise, the aluminum casting market is expected to expand, offering opportunities for innovation and development in casting techniques and materials.

Die Casting, Permanent Molding Casting, Sand Casting, Other in the Commercial Vehicle Aluminum Casting - Global Market:

Die casting, permanent molding casting, sand casting, and other methods are integral to the commercial vehicle aluminum casting market. Die casting is a popular method due to its ability to produce complex shapes with high precision and excellent surface finish. It involves forcing molten aluminum into a mold cavity under high pressure, which allows for the production of intricate parts with tight tolerances. This method is highly efficient and suitable for mass production, making it ideal for the automotive industry where large volumes of parts are required. Permanent molding casting, on the other hand, involves pouring molten aluminum into a reusable mold. This method is known for producing parts with superior mechanical properties and a good surface finish. It is often used for components that require high strength and durability, such as engine blocks and transmission cases. Sand casting is another widely used method, particularly for larger parts that do not require high precision. It involves creating a mold from a sand mixture, into which molten aluminum is poured. Sand casting is versatile and cost-effective, making it suitable for producing a wide range of parts. Other methods, such as investment casting and gravity die casting, are also used in the commercial vehicle aluminum casting market, each offering unique advantages in terms of cost, precision, and production speed. These casting methods are essential for meeting the diverse needs of the commercial vehicle industry, providing manufacturers with the flexibility to produce a wide range of components with varying specifications.

Truck, Special Vehicle, Others in the Commercial Vehicle Aluminum Casting - Global Market:

The usage of commercial vehicle aluminum casting is prevalent in various areas, including trucks, special vehicles, and others. In the truck segment, aluminum casting is used to produce components such as engine blocks, cylinder heads, transmission cases, and wheels. The lightweight nature of aluminum helps reduce the overall weight of trucks, leading to improved fuel efficiency and lower emissions. This is particularly important for long-haul trucks, where fuel consumption is a significant cost factor. In special vehicles, which include construction vehicles, agricultural machinery, and military vehicles, aluminum casting is used to manufacture parts that require high strength and durability. The ability to produce complex shapes with aluminum casting allows for the design of components that can withstand harsh operating conditions and heavy loads. Additionally, the corrosion resistance of aluminum makes it suitable for use in environments where vehicles are exposed to moisture and chemicals. Other applications of commercial vehicle aluminum casting include the production of chassis components, suspension parts, and brake systems. The versatility of aluminum casting allows manufacturers to produce a wide range of parts that meet the specific requirements of different vehicle types. As the demand for commercial vehicles continues to grow, the use of aluminum casting is expected to increase, driven by the need for lightweight, durable, and efficient components.

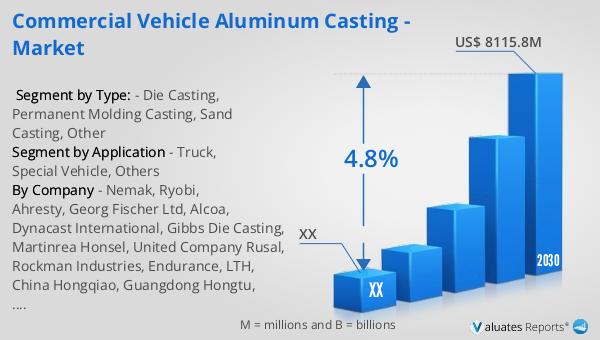

Commercial Vehicle Aluminum Casting - Global Market Outlook:

The global market for commercial vehicle aluminum casting was valued at approximately $5,894 million in 2023. It is projected to grow to a revised size of $8,115.8 million by 2030, with a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. Currently, over 90% of the world's automobiles are concentrated in Asia, Europe, and North America. Asia leads in automobile production, accounting for 56% of the global output, followed by Europe at 20% and North America at 16%. This concentration of vehicle production in these regions significantly influences the commercial vehicle aluminum casting market. The growth in these regions is driven by factors such as increasing demand for fuel-efficient vehicles, stringent environmental regulations, and advancements in casting technologies. As the automotive industry continues to evolve, the commercial vehicle aluminum casting market is expected to expand, offering opportunities for innovation and development in casting techniques and materials.

| Report Metric | Details |

| Report Name | Commercial Vehicle Aluminum Casting - Market |

| Forecasted market size in 2030 | US$ 8115.8 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Nemak, Ryobi, Ahresty, Georg Fischer Ltd, Alcoa, Dynacast International, Gibbs Die Casting, Martinrea Honsel, United Company Rusal, Rockman Industries, Endurance, LTH, China Hongqiao, Guangdong Hongtu, Hongte, Wencan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |