What is Blister Machine Tooling - Global Market?

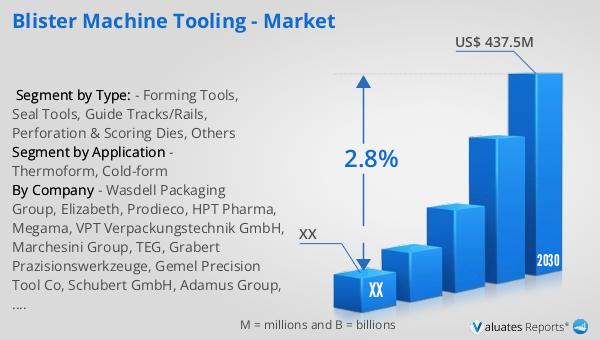

Blister machine tooling refers to the specialized equipment used in the production of blister packs, which are commonly used for packaging pharmaceuticals, consumer goods, and food products. These machines are essential for creating the plastic or aluminum cavities that hold individual items securely in place. The global market for blister machine tooling is a dynamic and evolving sector, driven by the increasing demand for efficient and reliable packaging solutions. As industries continue to prioritize product safety, tamper resistance, and extended shelf life, the need for advanced blister packaging technologies has grown. This market encompasses a wide range of tools and components, including forming tools, seal tools, guide tracks, perforation and scoring dies, and other specialized equipment. Each component plays a crucial role in ensuring the precision and quality of the final blister pack. The global market for blister machine tooling was valued at approximately $361.6 million in 2023, with projections indicating a growth trajectory that will see it reach around $437.5 million by 2030. This growth is driven by technological advancements, increased automation, and the expanding pharmaceutical and consumer goods sectors. As companies strive to enhance their packaging capabilities, the demand for innovative blister machine tooling solutions is expected to continue rising.

Forming Tools, Seal Tools, Guide Tracks/Rails, Perforation & Scoring Dies, Others in the Blister Machine Tooling - Global Market:

Forming tools are a critical component of blister machine tooling, responsible for shaping the plastic or aluminum material into the desired cavity shape. These tools must be designed with precision to ensure that the formed cavities meet the exact specifications required for the product being packaged. The forming process involves heating the material to a pliable state and then using the forming tool to mold it into the desired shape. This requires a high degree of accuracy to ensure that the cavities are uniform and capable of securely holding the product. Seal tools, on the other hand, are used to create a secure seal between the formed blister and the backing material, which is typically a foil or paperboard. This seal is crucial for maintaining the integrity of the package and protecting the contents from external factors such as moisture and contamination. Guide tracks or rails are essential for ensuring the smooth movement of the blister material through the machine. They help maintain alignment and prevent misfeeds, which can lead to defects in the final product. Perforation and scoring dies are used to create easy-to-open features in the blister pack, such as tear lines or perforations. These features enhance the user experience by making it easier to access the product without damaging the packaging. Other components of blister machine tooling may include cutting dies, which are used to trim the excess material from the formed blister, and inspection systems, which ensure that each blister pack meets quality standards. The global market for these tools is driven by the need for high-quality, reliable packaging solutions that can meet the demands of various industries. As companies continue to innovate and improve their packaging processes, the demand for advanced blister machine tooling is expected to grow.

Thermoform, Cold-form in the Blister Machine Tooling - Global Market:

Blister machine tooling is used in two primary types of blister packaging processes: thermoforming and cold-forming. Thermoforming is a process that involves heating a plastic sheet until it becomes pliable and then forming it into the desired shape using a mold. This method is widely used for packaging products that require a clear view of the contents, such as pharmaceuticals and consumer goods. The thermoforming process is highly efficient and allows for the production of large volumes of blister packs in a relatively short amount of time. It also offers flexibility in terms of design, allowing manufacturers to create custom shapes and sizes to meet specific packaging needs. Cold-forming, on the other hand, involves shaping a laminate material, typically aluminum, without the use of heat. This process is used for products that require a high level of protection from moisture and light, such as certain pharmaceuticals. Cold-forming provides an excellent barrier to external elements, ensuring the product remains safe and effective throughout its shelf life. The choice between thermoforming and cold-forming depends on the specific requirements of the product being packaged. Both processes require precise tooling to ensure the quality and consistency of the final product. The global market for blister machine tooling is driven by the increasing demand for both thermoformed and cold-formed blister packs, as industries continue to seek efficient and reliable packaging solutions. As technology advances, the capabilities of blister machine tooling are expected to expand, offering even greater precision and efficiency in the packaging process.

Blister Machine Tooling - Global Market Outlook:

The global market for blister machine tooling was valued at approximately $361.6 million in 2023, with expectations of reaching around $437.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.8% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for advanced packaging solutions across various industries, including pharmaceuticals, consumer goods, and food products. The North American market, in particular, is poised for significant growth, driven by technological advancements and the expanding pharmaceutical sector. While specific figures for the North American market were not provided, it is expected to contribute substantially to the overall growth of the global market. The demand for blister machine tooling in this region is fueled by the need for efficient, reliable, and tamper-resistant packaging solutions that meet stringent regulatory requirements. As companies continue to innovate and improve their packaging processes, the market for blister machine tooling is expected to expand, offering new opportunities for manufacturers and suppliers. The focus on sustainability and environmentally friendly packaging solutions is also expected to drive growth in this market, as companies seek to reduce their environmental impact while maintaining the quality and integrity of their products.

| Report Metric | Details |

| Report Name | Blister Machine Tooling - Market |

| Forecasted market size in 2030 | US$ 437.5 million |

| CAGR | 2.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Wasdell Packaging Group, Elizabeth, Prodieco, HPT Pharma, Megama, VPT Verpackungstechnik GmbH, Marchesini Group, TEG, Grabert Prazisionswerkzeuge, Gemel Precision Tool Co, Schubert GmbH, Adamus Group, Borsch Engineering, Inc, Accupack, Prebelli Industries, Thomas Packaging LLC, Dordan Manufacturing, Hangzhou Demei Pharma Technology Co.,Ltd, Toolrite, Forstek D.O.O. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |