What is Passenger Vehicle Aluminum Casting - Global Market?

Passenger vehicle aluminum casting is a significant segment within the global automotive industry, focusing on the production of aluminum components for vehicles. This market is driven by the increasing demand for lightweight materials that enhance fuel efficiency and reduce emissions. Aluminum casting involves the process of pouring molten aluminum into molds to create various parts used in passenger vehicles, such as engine blocks, transmission cases, and structural components. The use of aluminum in vehicles is favored due to its lightweight nature, corrosion resistance, and ability to absorb crash energy, which enhances vehicle safety. As automakers strive to meet stringent environmental regulations and consumer demand for more efficient vehicles, the adoption of aluminum casting in passenger vehicles continues to grow. This market is characterized by technological advancements in casting techniques, which improve the quality and performance of aluminum components. Additionally, the global market is influenced by regional production trends, with significant contributions from Asia, Europe, and North America. The ongoing shift towards electric vehicles also presents new opportunities for aluminum casting, as these vehicles require lightweight materials to offset the weight of batteries and improve range. Overall, the passenger vehicle aluminum casting market plays a crucial role in the evolution of the automotive industry towards more sustainable and efficient transportation solutions.

Die Casting, Permanent Molding Casting, Sand Casting, Other in the Passenger Vehicle Aluminum Casting - Global Market:

Die casting, permanent molding casting, sand casting, and other methods are integral to the passenger vehicle aluminum casting market, each offering unique advantages and applications. Die casting is a highly efficient process where molten aluminum is forced into a mold cavity under high pressure. This method is ideal for producing complex shapes with high dimensional accuracy and smooth surface finishes, making it suitable for components like engine blocks and transmission cases. Die casting is favored for its ability to produce large volumes of parts quickly, which is essential for meeting the high demand in the automotive industry. Permanent molding casting, on the other hand, involves pouring molten aluminum into a reusable metal mold. This method is known for producing parts with superior mechanical properties and a finer grain structure compared to sand casting. It is often used for components that require high strength and durability, such as suspension parts and wheels. Sand casting is a more traditional method where sand is used to create the mold. It is highly versatile and cost-effective, making it suitable for producing large and complex parts that do not require high precision. Sand casting is often used for prototype development and low-volume production runs. Other casting methods, such as investment casting and gravity die casting, also play a role in the passenger vehicle aluminum casting market. Investment casting, also known as lost-wax casting, is used for producing intricate parts with excellent surface finish and dimensional accuracy. Gravity die casting, similar to permanent molding, involves pouring molten aluminum into a mold under the force of gravity. This method is used for producing medium to large-sized parts with good mechanical properties. Each of these casting methods contributes to the diversity and adaptability of the passenger vehicle aluminum casting market, allowing manufacturers to choose the most suitable process based on the specific requirements of the component being produced. As the automotive industry continues to evolve, advancements in casting technologies are expected to further enhance the quality and performance of aluminum components, supporting the industry's shift towards more efficient and sustainable vehicles.

Coupes, Sedans, Hatchbacks, Others in the Passenger Vehicle Aluminum Casting - Global Market:

The usage of passenger vehicle aluminum casting in coupes, sedans, hatchbacks, and other vehicle types highlights the versatility and importance of aluminum components in modern automotive design. Coupes, known for their sporty and stylish appearance, benefit from aluminum casting through the production of lightweight components that enhance performance and fuel efficiency. Aluminum is often used in the construction of engine parts, suspension systems, and body panels, contributing to the overall agility and handling of the vehicle. Sedans, which are popular for their practicality and comfort, also utilize aluminum casting to improve fuel economy and reduce emissions. The use of aluminum in engine blocks, transmission cases, and structural components helps to lower the overall weight of the vehicle, resulting in better fuel efficiency and reduced environmental impact. Hatchbacks, known for their compact size and versatility, benefit from aluminum casting in similar ways. The lightweight nature of aluminum allows for the production of components that do not compromise the vehicle's performance or cargo capacity. Additionally, the use of aluminum in safety-critical components, such as crash structures and crumple zones, enhances the safety of hatchbacks by absorbing impact energy during collisions. Other vehicle types, including SUVs and crossovers, also leverage the advantages of aluminum casting. These vehicles often require robust and durable components to handle various driving conditions and terrains. Aluminum casting provides the necessary strength and durability while keeping the vehicle's weight in check, which is crucial for maintaining fuel efficiency and performance. The adoption of aluminum casting across different vehicle types is driven by the automotive industry's commitment to sustainability and efficiency. As regulations become more stringent and consumer preferences shift towards greener vehicles, the demand for aluminum components is expected to grow. This trend is further supported by the increasing popularity of electric vehicles, which rely on lightweight materials to offset the weight of batteries and extend driving range. Overall, the use of passenger vehicle aluminum casting in coupes, sedans, hatchbacks, and other vehicle types underscores the material's critical role in shaping the future of the automotive industry.

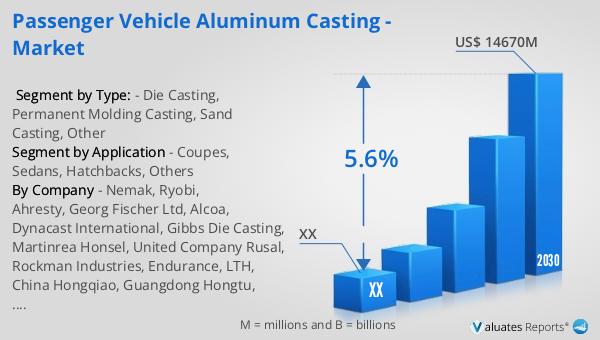

Passenger Vehicle Aluminum Casting - Global Market Outlook:

The global market for passenger vehicle aluminum casting was valued at approximately $9,915 million in 2023. It is projected to expand to a revised size of $14,670 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period from 2024 to 2030. Currently, over 90% of the world's automobiles are concentrated in the continents of Asia, Europe, and North America. Among these, Asia leads with 56% of global automobile production, followed by Europe at 20%, and North America at 16%. This distribution highlights the significant role these regions play in the automotive industry and, consequently, in the passenger vehicle aluminum casting market. The growth in this market is driven by the increasing demand for lightweight and fuel-efficient vehicles, as well as the ongoing shift towards electric vehicles. As automakers strive to meet environmental regulations and consumer expectations, the adoption of aluminum casting is expected to rise, particularly in regions with high automotive production. The market's expansion is also supported by technological advancements in casting processes, which enhance the quality and performance of aluminum components. As the industry continues to evolve, the passenger vehicle aluminum casting market is poised to play a crucial role in the development of more sustainable and efficient transportation solutions.

| Report Metric | Details |

| Report Name | Passenger Vehicle Aluminum Casting - Market |

| Forecasted market size in 2030 | US$ 14670 million |

| CAGR | 5.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Nemak, Ryobi, Ahresty, Georg Fischer Ltd, Alcoa, Dynacast International, Gibbs Die Casting, Martinrea Honsel, United Company Rusal, Rockman Industries, Endurance, LTH, China Hongqiao, Guangdong Hongtu, Hongte, Wencan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |