What is Global Industrial Anhydrous Hydrogen Fluoride Market?

The Global Industrial Anhydrous Hydrogen Fluoride Market is a significant segment within the chemical industry, focusing on the production and distribution of anhydrous hydrogen fluoride (AHF). AHF is a colorless, fuming liquid or gas that is highly corrosive and is used as a precursor to many important compounds, including fluorocarbons and aluminum trifluoride. This market is driven by the demand for AHF in various industrial applications, such as the production of refrigerants, pharmaceuticals, and high-performance plastics. The market's growth is influenced by factors such as technological advancements, regulatory policies, and the increasing need for efficient and sustainable chemical processes. Companies operating in this market are continually investing in research and development to enhance the quality and efficiency of AHF production. The global reach of this market is extensive, with key players located in regions such as North America, Europe, and Asia-Pacific, each contributing to the overall supply chain. The market's dynamics are shaped by the interplay of supply and demand, raw material availability, and the competitive landscape, which includes both established companies and emerging players.

Hydrogen Fluoride Content: >99.92%, Hydrogen Fluoride Content: <99.92% in the Global Industrial Anhydrous Hydrogen Fluoride Market:

Hydrogen fluoride content is a critical factor in the Global Industrial Anhydrous Hydrogen Fluoride Market, with two primary categories: >99.92% and <99.92%. The >99.92% hydrogen fluoride content is considered high purity and is essential for applications requiring stringent quality standards. This high-purity AHF is predominantly used in the electronics industry for etching and cleaning processes, where impurities can significantly affect the performance of electronic components. The demand for high-purity AHF is driven by the rapid growth of the electronics sector, particularly in the production of semiconductors and integrated circuits. On the other hand, hydrogen fluoride content of <99.92% is used in applications where ultra-high purity is not as critical. This includes the production of refrigerants, aluminum fluoride, and various chemical intermediates. The lower purity AHF is more cost-effective and is suitable for large-scale industrial applications where the presence of minor impurities does not compromise the end product's quality. The choice between high and lower purity AHF depends on the specific requirements of the application, cost considerations, and regulatory compliance. Companies in the AHF market must balance these factors to meet the diverse needs of their customers while maintaining profitability. The production of AHF with varying purity levels involves different manufacturing processes and quality control measures to ensure that the final product meets the desired specifications. The market for AHF with different purity levels is influenced by technological advancements, environmental regulations, and the availability of raw materials. As industries continue to evolve, the demand for both high and lower purity AHF is expected to grow, driven by the need for efficient and sustainable chemical processes. The competitive landscape of the AHF market is characterized by the presence of both large multinational corporations and smaller specialized companies, each vying for market share by offering products that meet the specific needs of their customers. The ability to produce AHF with the desired purity levels is a key differentiator in this market, with companies investing in research and development to enhance their production capabilities and maintain a competitive edge. The global nature of the AHF market means that companies must also navigate complex regulatory environments and trade dynamics to ensure the smooth supply of their products to customers worldwide.

Chemical Industry, Mining, Metallurgy, Others in the Global Industrial Anhydrous Hydrogen Fluoride Market:

The Global Industrial Anhydrous Hydrogen Fluoride Market plays a crucial role in several industries, including the chemical industry, mining, metallurgy, and others. In the chemical industry, AHF is used as a key raw material in the production of fluorocarbons, which are essential for manufacturing refrigerants, solvents, and propellants. The demand for AHF in this sector is driven by the need for environmentally friendly and energy-efficient products, as well as the development of new chemical processes that require high-purity hydrogen fluoride. In the mining industry, AHF is used for the extraction and processing of minerals, particularly in the production of aluminum and uranium. Its ability to react with various ores makes it an invaluable tool for separating valuable metals from their natural sources. The use of AHF in mining is influenced by factors such as the availability of mineral resources, environmental regulations, and the demand for metals in various industrial applications. In the metallurgy industry, AHF is used for the production of aluminum fluoride, which is a critical component in the aluminum smelting process. The demand for aluminum, driven by its lightweight and corrosion-resistant properties, has led to increased consumption of AHF in this sector. Additionally, AHF is used in the production of other metal fluorides, which are used in various metallurgical processes. The versatility of AHF makes it an essential component in the production of high-performance materials and alloys. Beyond these industries, AHF is also used in the production of pharmaceuticals, agrochemicals, and high-performance plastics. Its ability to act as a catalyst and reactant in various chemical reactions makes it a valuable tool for developing new products and processes. The demand for AHF in these sectors is driven by the need for innovative solutions that meet the evolving needs of consumers and industries. The global nature of the AHF market means that companies must navigate complex supply chains and regulatory environments to ensure the smooth delivery of their products to customers worldwide. The ability to adapt to changing market conditions and customer requirements is critical for success in this dynamic and competitive market.

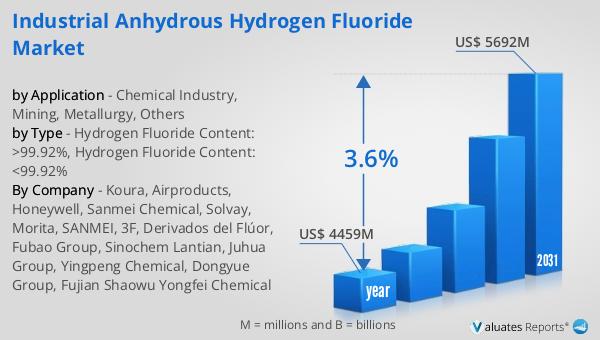

Global Industrial Anhydrous Hydrogen Fluoride Market Outlook:

The global market for Industrial Anhydrous Hydrogen Fluoride was valued at approximately $4,459 million in 2024. It is anticipated to grow steadily, reaching an estimated size of $5,692 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 3.6% over the forecast period. The market's expansion is driven by increasing demand across various industries, including electronics, chemicals, and metallurgy, where AHF is a critical component. The rising need for high-purity hydrogen fluoride in the electronics industry, particularly for semiconductor manufacturing, is a significant factor contributing to this growth. Additionally, the chemical industry's demand for AHF as a precursor to fluorocarbons and other compounds further supports market expansion. The market's growth is also influenced by technological advancements and the development of new applications for AHF, which drive innovation and create new opportunities for market players. Companies operating in this market are investing in research and development to enhance their production capabilities and meet the evolving needs of their customers. The competitive landscape is characterized by the presence of both established players and emerging companies, each striving to capture a share of this growing market. As the market continues to evolve, companies must navigate complex regulatory environments and trade dynamics to ensure the smooth supply of their products to customers worldwide. The ability to adapt to changing market conditions and customer requirements is critical for success in this dynamic and competitive market.

| Report Metric | Details |

| Report Name | Industrial Anhydrous Hydrogen Fluoride Market |

| Accounted market size in year | US$ 4459 million |

| Forecasted market size in 2031 | US$ 5692 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Koura, Airproducts, Honeywell, Sanmei Chemical, Solvay, Morita, SANMEI, 3F, Derivados del Flúor, Fubao Group, Sinochem Lantian, Juhua Group, Yingpeng Chemical, Dongyue Group, Fujian Shaowu Yongfei Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |