What is Global Anti-block Masterbatch Market?

The Global Anti-block Masterbatch Market is a specialized segment within the broader plastics and polymers industry. Anti-block masterbatches are additives used in the production of plastic films to prevent them from sticking together, a phenomenon known as blocking. This is particularly important in industries where plastic films are used for packaging, as blocking can lead to inefficiencies and product damage. The market for these masterbatches is driven by the increasing demand for high-quality packaging solutions across various sectors, including food and beverage, pharmaceuticals, and consumer goods. The anti-block masterbatch market is characterized by a diverse range of products, each tailored to meet specific requirements of different applications. These products are typically composed of fine particles of inorganic or organic materials that are dispersed in a polymer matrix. The global market is witnessing growth due to advancements in technology and the rising awareness about the benefits of using anti-block masterbatches, such as improved processing efficiency and enhanced product quality. As industries continue to seek innovative packaging solutions, the demand for anti-block masterbatches is expected to rise, making it a vital component in the modern manufacturing landscape.

Organic Type, Inorganic Type in the Global Anti-block Masterbatch Market:

In the Global Anti-block Masterbatch Market, there are two primary types of anti-block agents: organic and inorganic. Organic anti-block agents are typically derived from natural sources and are known for their compatibility with a wide range of polymers. These agents are often used in applications where environmental considerations are paramount, as they tend to be more biodegradable and less harmful to the environment. Organic anti-block agents work by creating a micro-rough surface on the film, which reduces the contact area between layers and thus minimizes blocking. Common organic anti-block agents include fatty acid amides and vegetable-based waxes. These materials are particularly favored in applications where food contact is involved, as they are generally recognized as safe and non-toxic. On the other hand, inorganic anti-block agents are composed of mineral-based materials such as silica, talc, and calcium carbonate. These agents are highly effective in reducing blocking due to their ability to create a physical barrier between film layers. Inorganic anti-block agents are often preferred in applications where high-temperature processing is required, as they tend to be more stable under such conditions. Additionally, inorganic agents are known for their cost-effectiveness and durability, making them a popular choice in industrial applications. The choice between organic and inorganic anti-block agents depends largely on the specific requirements of the application, including factors such as cost, environmental impact, and performance characteristics. As the demand for sustainable and efficient packaging solutions continues to grow, manufacturers are increasingly exploring the use of both organic and inorganic anti-block agents to meet the diverse needs of the market. The development of new and innovative anti-block masterbatches is also being driven by advancements in material science, which are enabling the creation of products with enhanced performance and reduced environmental impact. This ongoing innovation is expected to play a crucial role in the future growth of the Global Anti-block Masterbatch Market, as manufacturers strive to meet the evolving demands of consumers and regulatory bodies.

Bags, Film, Others in the Global Anti-block Masterbatch Market:

The usage of Global Anti-block Masterbatch Market products is widespread across various applications, with bags and films being among the most prominent. In the production of plastic bags, anti-block masterbatches are essential for ensuring that the bags do not stick together during manufacturing, storage, or transportation. This is particularly important for industries such as retail and food service, where the ease of handling and separation of bags is crucial for operational efficiency. Anti-block masterbatches help to maintain the quality and functionality of plastic bags, ensuring that they can be easily opened and used by consumers. In the film industry, anti-block masterbatches are used to enhance the performance of plastic films used in packaging, agriculture, and industrial applications. These masterbatches prevent the films from sticking together, which can lead to defects and inefficiencies in the production process. By reducing blocking, anti-block masterbatches help to improve the clarity, gloss, and overall appearance of plastic films, making them more attractive to consumers. In addition to bags and films, anti-block masterbatches are also used in a variety of other applications, including the production of sheets, laminates, and coatings. These products benefit from the anti-block properties of the masterbatches, which help to improve their performance and durability. The versatility of anti-block masterbatches makes them an essential component in the production of a wide range of plastic products, contributing to their growing demand in the global market. As industries continue to seek innovative solutions to improve the quality and functionality of their products, the use of anti-block masterbatches is expected to expand, driving further growth in the market.

Global Anti-block Masterbatch Market Outlook:

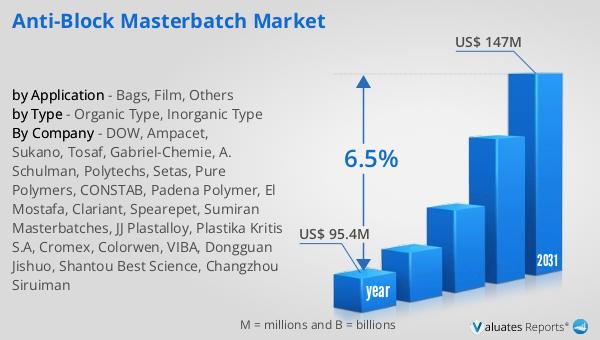

The outlook for the Global Anti-block Masterbatch Market is promising, with significant growth projected in the coming years. In 2024, the market was valued at approximately US$ 95.4 million, reflecting the strong demand for anti-block solutions across various industries. This demand is expected to continue to rise, driven by the increasing need for high-quality packaging and the growing awareness of the benefits of using anti-block masterbatches. By 2031, the market is projected to reach a revised size of US$ 147 million, representing a compound annual growth rate (CAGR) of 6.5% during the forecast period. This growth is indicative of the expanding applications of anti-block masterbatches and the ongoing innovation in the field. Manufacturers are continually developing new and improved products to meet the evolving needs of consumers and industries, contributing to the market's upward trajectory. The increasing focus on sustainability and environmental responsibility is also playing a role in shaping the future of the market, as companies seek to develop eco-friendly solutions that align with regulatory requirements and consumer preferences. As a result, the Global Anti-block Masterbatch Market is poised for continued growth and development, offering significant opportunities for manufacturers and stakeholders in the industry.

| Report Metric | Details |

| Report Name | Anti-block Masterbatch Market |

| Accounted market size in year | US$ 95.4 million |

| Forecasted market size in 2031 | US$ 147 million |

| CAGR | 6.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DOW, Ampacet, Sukano, Tosaf, Gabriel-Chemie, A. Schulman, Polytechs, Setas, Pure Polymers, CONSTAB, Padena Polymer, El Mostafa, Clariant, Spearepet, Sumiran Masterbatches, JJ Plastalloy, Plastika Kritis S.A, Cromex, Colorwen, VIBA, Dongguan Jishuo, Shantou Best Science, Changzhou Siruiman |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |