What is Global Low Temperature Sintered Conductive Silver Paste Market?

The Global Low Temperature Sintered Conductive Silver Paste Market is a specialized segment within the broader conductive materials industry, focusing on the development and application of silver pastes that can be sintered at relatively low temperatures. These pastes are primarily used in electronic applications where high conductivity and thermal stability are required, but where the substrates or components cannot withstand high processing temperatures. The market is driven by the increasing demand for miniaturized and efficient electronic devices, which require advanced materials that can provide reliable electrical connections without compromising the integrity of the components. The low-temperature sintering process allows for the integration of silver paste into delicate electronic assemblies, such as those found in consumer electronics, automotive electronics, and renewable energy systems. This market is characterized by continuous innovation, as manufacturers strive to improve the performance characteristics of their products, such as conductivity, adhesion, and thermal stability, while also reducing costs and environmental impact. The growth of this market is supported by advancements in nanotechnology and material science, which enable the development of new formulations and processing techniques that enhance the properties and applications of conductive silver pastes.

Nano Silver Paste, Micron Silver Paste in the Global Low Temperature Sintered Conductive Silver Paste Market:

Nano Silver Paste and Micron Silver Paste are two key products within the Global Low Temperature Sintered Conductive Silver Paste Market, each offering distinct advantages and applications. Nano Silver Paste is formulated using silver nanoparticles, which are typically less than 100 nanometers in size. These nanoparticles provide a high surface area to volume ratio, which enhances the paste's conductivity and allows for sintering at lower temperatures compared to traditional silver pastes. This makes Nano Silver Paste particularly suitable for applications where thermal sensitivity is a concern, such as in flexible electronics and organic substrates. The small particle size also enables the paste to be applied in very thin layers, which is advantageous for miniaturized electronic components and circuits. On the other hand, Micron Silver Paste is composed of larger silver particles, usually in the range of one to several micrometers. While it may require slightly higher sintering temperatures than its nano counterpart, Micron Silver Paste offers excellent bulk conductivity and is often used in applications where thicker conductive layers are needed, such as in power electronics and certain types of sensors. Both types of silver pastes are integral to the development of advanced electronic devices, but their specific applications depend on the requirements of the end-use products. For instance, Nano Silver Paste is often preferred in applications where fine line printing and high precision are necessary, such as in the production of touch screens and photovoltaic cells. Its ability to form conductive paths at low temperatures without damaging sensitive components makes it ideal for these applications. Meanwhile, Micron Silver Paste is favored in scenarios where robust mechanical properties and high current carrying capacity are required, such as in automotive electronics and industrial sensors. The choice between Nano and Micron Silver Paste is influenced by factors such as the desired electrical and thermal performance, the nature of the substrate, and the processing conditions. Manufacturers in the Global Low Temperature Sintered Conductive Silver Paste Market continue to innovate and optimize these products to meet the evolving demands of the electronics industry. This includes developing hybrid pastes that combine nano and micron-sized particles to achieve a balance of properties, as well as exploring new additives and binders that enhance performance. As the market grows, the distinction between Nano and Micron Silver Paste becomes increasingly important, as each offers unique benefits that can be leveraged to improve the performance and reliability of electronic devices.

Chip Packaging, Semiconductor Bonding, Integrated Circuits in the Global Low Temperature Sintered Conductive Silver Paste Market:

The Global Low Temperature Sintered Conductive Silver Paste Market plays a crucial role in several key areas of electronics manufacturing, including chip packaging, semiconductor bonding, and integrated circuits. In chip packaging, conductive silver paste is used to create reliable electrical connections between the semiconductor die and the package leads. The low-temperature sintering capability of these pastes is particularly beneficial in this application, as it allows for the use of temperature-sensitive substrates and components without risking thermal damage. This is especially important in the production of advanced packaging solutions, such as flip-chip and wafer-level packaging, where precision and reliability are paramount. In semiconductor bonding, conductive silver paste serves as an adhesive that not only provides electrical connectivity but also helps dissipate heat generated by the semiconductor device. The thermal conductivity of silver makes it an ideal material for this purpose, ensuring that heat is efficiently transferred away from the active regions of the device, thereby enhancing performance and longevity. The low-temperature sintering process further aids in maintaining the integrity of the semiconductor materials, which can be sensitive to high temperatures. Integrated circuits (ICs) also benefit from the use of low-temperature sintered conductive silver paste, particularly in the formation of interconnects and conductive traces. The ability to apply the paste in fine lines and patterns is essential for the miniaturization of ICs, as it allows for the creation of complex circuit layouts within a limited space. The high conductivity of silver ensures that these interconnects can carry the necessary electrical signals with minimal resistance, contributing to the overall efficiency of the IC. Additionally, the low-temperature processing capability of the paste supports the integration of ICs with other components on multi-layered circuit boards, where thermal management is a critical concern. Overall, the use of low-temperature sintered conductive silver paste in these areas underscores its importance in the advancement of modern electronics. By enabling the production of smaller, more efficient, and more reliable electronic devices, this market supports the ongoing trend towards miniaturization and increased functionality in consumer electronics, automotive systems, and industrial applications.

Global Low Temperature Sintered Conductive Silver Paste Market Outlook:

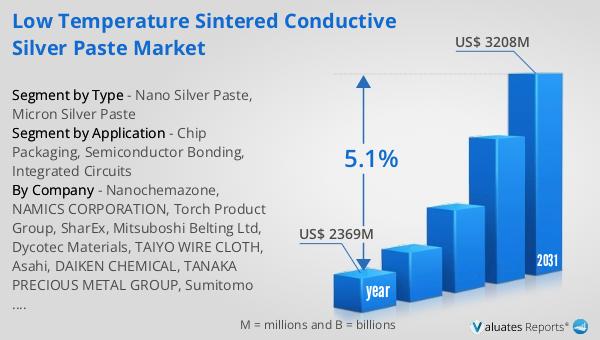

The global market for Low Temperature Sintered Conductive Silver Paste was valued at approximately $2,369 million in 2024, and it is anticipated to expand to a revised size of around $3,208 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.1% over the forecast period. This market outlook reflects the increasing demand for advanced conductive materials that can meet the stringent requirements of modern electronic devices. The ability of low-temperature sintered conductive silver paste to provide high conductivity and thermal stability while being compatible with temperature-sensitive substrates makes it an attractive choice for manufacturers across various industries. As the electronics industry continues to evolve, driven by trends such as miniaturization, increased functionality, and the integration of new technologies, the demand for innovative materials like low-temperature sintered conductive silver paste is expected to rise. This market growth is further supported by ongoing research and development efforts aimed at enhancing the performance characteristics of these pastes, such as improving their adhesion, conductivity, and environmental sustainability. As a result, the Global Low Temperature Sintered Conductive Silver Paste Market is poised to play a pivotal role in the future of electronics manufacturing, providing the materials necessary to support the next generation of electronic devices.

| Report Metric | Details |

| Report Name | Low Temperature Sintered Conductive Silver Paste Market |

| Accounted market size in year | US$ 2369 million |

| Forecasted market size in 2031 | US$ 3208 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nanochemazone, NAMICS CORPORATION, Torch Product Group, SharEx, Mitsuboshi Belting Ltd, Dycotec Materials, TAIYO WIRE CLOTH, Asahi, DAIKEN CHEMICAL, TANAKA PRECIOUS METAL GROUP, Sumitomo Bakelite, Shanghai Baoyin Electronic Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |