What is Global Nondestructive Testing of Wire Ropes Market?

The Global Nondestructive Testing (NDT) of Wire Ropes Market is a specialized segment within the broader field of nondestructive testing, focusing on the evaluation and inspection of wire ropes without causing any damage to them. Wire ropes are critical components in various industries, including construction, mining, oil and gas, and transportation, where they are used for lifting, hoisting, and securing loads. The primary goal of nondestructive testing in this context is to ensure the safety, reliability, and longevity of wire ropes by detecting any potential defects or weaknesses that could lead to failure. This market encompasses a range of testing methods and technologies designed to assess the integrity of wire ropes, such as electromagnetic testing, ultrasonic testing, and visual inspection. As industries continue to prioritize safety and efficiency, the demand for advanced NDT solutions for wire ropes is expected to grow, driven by the need to minimize downtime, reduce maintenance costs, and prevent accidents. The market is characterized by ongoing technological advancements, with companies investing in research and development to enhance the accuracy and effectiveness of testing methods. Overall, the Global Nondestructive Testing of Wire Ropes Market plays a crucial role in ensuring the safe and efficient operation of various industrial applications.

Electromagnetic Testing, Ultrasonic Testing, Others in the Global Nondestructive Testing of Wire Ropes Market:

Electromagnetic Testing (ET) is one of the most widely used methods in the Global Nondestructive Testing of Wire Ropes Market. This technique involves the use of electromagnetic fields to detect flaws and irregularities in wire ropes. By passing an electric current through the wire rope, electromagnetic testing can identify variations in the magnetic field, which may indicate the presence of defects such as broken wires, corrosion, or wear. This method is particularly effective for detecting surface and near-surface defects, making it a popular choice for routine inspections. The advantage of electromagnetic testing lies in its ability to provide real-time results, allowing for immediate assessment and decision-making. Additionally, it is a non-contact method, meaning that it does not require physical contact with the wire rope, reducing the risk of further damage during the inspection process. Ultrasonic Testing (UT) is another critical method used in the nondestructive testing of wire ropes. This technique employs high-frequency sound waves to penetrate the wire rope and detect internal flaws. By analyzing the reflections of these sound waves, technicians can identify defects such as internal cracks, voids, or inclusions. Ultrasonic testing is highly effective for detecting subsurface defects, providing a comprehensive assessment of the wire rope's integrity. One of the key benefits of ultrasonic testing is its ability to provide detailed information about the size, location, and nature of defects, enabling more accurate assessments and informed decision-making. However, this method requires skilled technicians and specialized equipment, which can increase the cost and complexity of the inspection process. In addition to electromagnetic and ultrasonic testing, there are several other methods used in the nondestructive testing of wire ropes. Visual inspection is one of the simplest and most cost-effective methods, involving a thorough examination of the wire rope's surface for signs of wear, corrosion, or damage. While visual inspection is limited in its ability to detect internal defects, it remains an essential part of the overall inspection process, providing valuable information about the rope's condition. Other methods, such as radiographic testing and acoustic emission testing, offer additional options for assessing the integrity of wire ropes. Radiographic testing uses X-rays or gamma rays to create images of the wire rope's internal structure, allowing for the detection of internal defects. Acoustic emission testing, on the other hand, involves listening for the sounds emitted by the wire rope as it is subjected to stress, which can indicate the presence of defects. Each of these methods has its own advantages and limitations, and the choice of method often depends on factors such as the type of wire rope, the specific application, and the level of detail required. Overall, the Global Nondestructive Testing of Wire Ropes Market offers a range of advanced testing methods and technologies designed to ensure the safety and reliability of wire ropes in various industrial applications.

Mining, Oil & Gas, Others in the Global Nondestructive Testing of Wire Ropes Market:

The Global Nondestructive Testing of Wire Ropes Market plays a vital role in several key industries, including mining, oil and gas, and others, by ensuring the safety and reliability of wire ropes used in these sectors. In the mining industry, wire ropes are essential for various applications, such as hoisting and transporting materials, as well as supporting structures in underground mines. The harsh conditions and heavy loads encountered in mining operations can lead to significant wear and tear on wire ropes, making regular inspections crucial to prevent accidents and ensure operational efficiency. Nondestructive testing methods, such as electromagnetic and ultrasonic testing, are employed to detect defects and assess the condition of wire ropes, allowing for timely maintenance and replacement. This not only enhances safety but also minimizes downtime and reduces maintenance costs, contributing to the overall productivity of mining operations. In the oil and gas industry, wire ropes are used in a wide range of applications, including drilling, lifting, and mooring. The demanding environments and high-stress conditions in this sector require wire ropes to be in optimal condition to prevent failures that could lead to costly downtime or environmental hazards. Nondestructive testing of wire ropes is essential for identifying potential issues before they become critical, ensuring the safe and efficient operation of oil and gas facilities. By employing advanced testing methods, companies can maintain the integrity of their wire ropes, reduce the risk of accidents, and comply with industry regulations and standards. Beyond mining and oil and gas, the Global Nondestructive Testing of Wire Ropes Market serves various other industries, such as construction, transportation, and maritime. In construction, wire ropes are used for lifting and securing loads, as well as supporting structures like cranes and elevators. Regular inspections through nondestructive testing help ensure the safety and reliability of these critical components, preventing accidents and enhancing the overall safety of construction sites. In the transportation sector, wire ropes are used in applications such as cable cars, bridges, and suspension systems. Nondestructive testing is crucial for maintaining the integrity of these systems, ensuring safe and reliable operation. Similarly, in the maritime industry, wire ropes are used for mooring, towing, and lifting operations, where they are exposed to harsh environmental conditions. Nondestructive testing helps identify potential issues, allowing for timely maintenance and replacement, thus ensuring the safety and efficiency of maritime operations. Overall, the Global Nondestructive Testing of Wire Ropes Market plays a critical role in ensuring the safety, reliability, and efficiency of wire ropes across various industries, contributing to the overall success and sustainability of these sectors.

Global Nondestructive Testing of Wire Ropes Market Outlook:

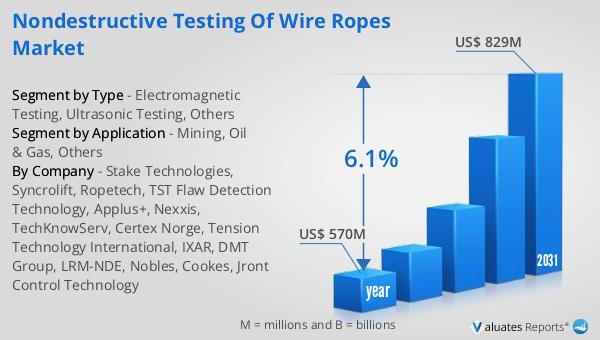

The global market for Nondestructive Testing of Wire Ropes was valued at $570 million in 2024 and is anticipated to expand to a revised size of $829 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.1% over the forecast period. This growth trajectory underscores the increasing importance of nondestructive testing in ensuring the safety and reliability of wire ropes across various industries. As industries continue to prioritize safety and operational efficiency, the demand for advanced testing solutions is expected to rise, driving market growth. The projected expansion of the market highlights the ongoing advancements in testing technologies and the growing awareness of the benefits of nondestructive testing. Companies are increasingly investing in research and development to enhance the accuracy and effectiveness of testing methods, further fueling market growth. The anticipated growth of the market also reflects the increasing adoption of nondestructive testing solutions in emerging economies, where industrialization and infrastructure development are driving demand for reliable and efficient testing methods. Overall, the Global Nondestructive Testing of Wire Ropes Market is poised for significant growth, driven by the need for enhanced safety, reliability, and efficiency in various industrial applications.

| Report Metric | Details |

| Report Name | Nondestructive Testing of Wire Ropes Market |

| Accounted market size in year | US$ 570 million |

| Forecasted market size in 2031 | US$ 829 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Stake Technologies, Syncrolift, Ropetech, TST Flaw Detection Technology, Applus+, Nexxis, TechKnowServ, Certex Norge, Tension Technology International, IXAR, DMT Group, LRM-NDE, Nobles, Cookes, Jront Control Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |