What is Global Mud Pump Piston Market?

The Global Mud Pump Piston Market is a specialized segment within the broader oilfield equipment industry, focusing on the production and distribution of pistons used in mud pumps. Mud pumps are essential components in drilling operations, particularly in the oil and gas sector, where they are used to circulate drilling fluid, commonly known as mud, down the drill string and back up the annulus. This process is crucial for cooling the drill bit, removing cuttings, and maintaining pressure control in the wellbore. The pistons in these pumps are critical as they drive the movement of the fluid, ensuring efficient and continuous operation. The market for mud pump pistons is influenced by factors such as advancements in drilling technologies, the expansion of oil and gas exploration activities, and the need for durable and efficient components that can withstand harsh operating conditions. As the demand for energy continues to rise globally, the market for mud pump pistons is expected to grow, driven by the need for reliable and high-performance equipment in drilling operations.

Rubber Piston, Urethane Piston in the Global Mud Pump Piston Market:

Rubber and urethane pistons are two primary types of pistons used in the Global Mud Pump Piston Market, each offering distinct advantages and applications. Rubber pistons are known for their flexibility and ability to create a tight seal within the pump cylinder, which is crucial for maintaining the pressure and flow of the drilling fluid. They are typically made from high-quality synthetic rubber compounds that provide excellent resistance to wear and tear, as well as chemical and temperature variations encountered in drilling environments. The elasticity of rubber pistons allows them to adapt to minor imperfections in the pump cylinder, ensuring a consistent seal and efficient operation. This adaptability makes rubber pistons a popular choice in various drilling applications, particularly where the conditions are not excessively harsh or abrasive. On the other hand, urethane pistons are favored for their superior durability and resistance to abrasion, making them ideal for more demanding drilling environments. Urethane, a type of polymer, offers a unique combination of toughness and flexibility, allowing pistons made from this material to withstand the rigors of high-pressure and high-temperature conditions often encountered in deep drilling operations. Urethane pistons are also highly resistant to chemical degradation, which is a significant advantage in environments where the drilling fluid may contain corrosive substances. The choice between rubber and urethane pistons often depends on the specific requirements of the drilling operation, including the nature of the drilling fluid, the operating conditions, and the desired lifespan of the piston. In some cases, operators may opt for a combination of both materials, using rubber pistons for less demanding sections of the drilling process and urethane pistons for more challenging conditions. The ongoing development of new materials and manufacturing techniques continues to enhance the performance and longevity of both rubber and urethane pistons, contributing to the overall growth and evolution of the Global Mud Pump Piston Market. As the industry advances, there is a continuous push towards improving the efficiency and reliability of these components, ensuring they meet the ever-increasing demands of modern drilling operations.

Oil & Gas Field, Mining Field, Others in the Global Mud Pump Piston Market:

The Global Mud Pump Piston Market plays a crucial role in various sectors, including the oil and gas field, mining field, and other industries that require efficient fluid handling systems. In the oil and gas field, mud pump pistons are integral to the drilling process, where they facilitate the circulation of drilling fluid, ensuring the removal of cuttings from the wellbore and maintaining the necessary pressure to prevent blowouts. The efficiency and reliability of mud pump pistons directly impact the success of drilling operations, making them a vital component in the exploration and production of oil and gas. In the mining field, mud pump pistons are used in similar applications, where they help in the transportation of slurry and other fluids necessary for mineral extraction processes. The harsh conditions in mining operations, such as abrasive materials and high-pressure environments, require pistons that can withstand significant wear and tear, making the choice of material and design critical for optimal performance. Beyond oil and gas and mining, mud pump pistons find applications in other industries that require robust fluid handling solutions, such as construction and water management. In these sectors, the ability to efficiently move fluids is essential for various processes, from concrete pumping to dewatering operations. The versatility and adaptability of mud pump pistons make them a valuable asset in any industry that relies on the movement of fluids under pressure. As these industries continue to evolve and expand, the demand for high-quality mud pump pistons is expected to grow, driven by the need for reliable and efficient equipment that can meet the challenges of modern operations. The ongoing advancements in piston materials and designs further enhance their performance, ensuring they remain a critical component in the fluid handling systems of various industries.

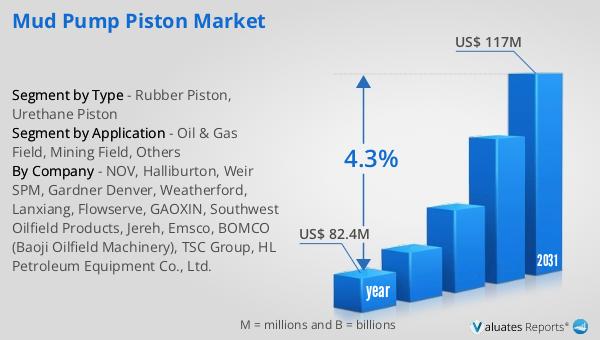

Global Mud Pump Piston Market Outlook:

The global market for Mud Pump Piston was valued at approximately $82.4 million in 2024, and it is anticipated to expand to a revised size of around $117 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. This upward trend in the market is indicative of the increasing demand for efficient and durable mud pump pistons, driven by the expansion of drilling activities and the need for reliable equipment in challenging environments. The growth in the market is also supported by technological advancements in piston materials and manufacturing processes, which enhance the performance and longevity of these critical components. As the energy sector continues to evolve, with a focus on exploring new reserves and optimizing existing operations, the demand for high-quality mud pump pistons is expected to rise. This growth trajectory reflects the broader trends in the oil and gas industry, where the emphasis on efficiency and sustainability drives the adoption of advanced equipment and technologies. The projected increase in market size underscores the importance of mud pump pistons in the global energy landscape, highlighting their role in ensuring the success and safety of drilling operations.

| Report Metric | Details |

| Report Name | Mud Pump Piston Market |

| Accounted market size in year | US$ 82.4 million |

| Forecasted market size in 2031 | US$ 117 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NOV, Halliburton, Weir SPM, Gardner Denver, Weatherford, Lanxiang, Flowserve, GAOXIN, Southwest Oilfield Products, Jereh, Emsco, BOMCO (Baoji Oilfield Machinery), TSC Group, HL Petroleum Equipment Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |